Torsen differentials offer superior torque distribution by using worm gears to provide enhanced traction and smoother handling in automotive applications. Helical differentials use angled gears to deliver quieter operation and efficient power transfer but may sacrifice some of the immediate torque bias capabilities found in Torsen systems. Choosing between a Torsen and helical diff depends on the desired balance of traction performance and noise reduction in vehicle dynamics.

Table of Comparison

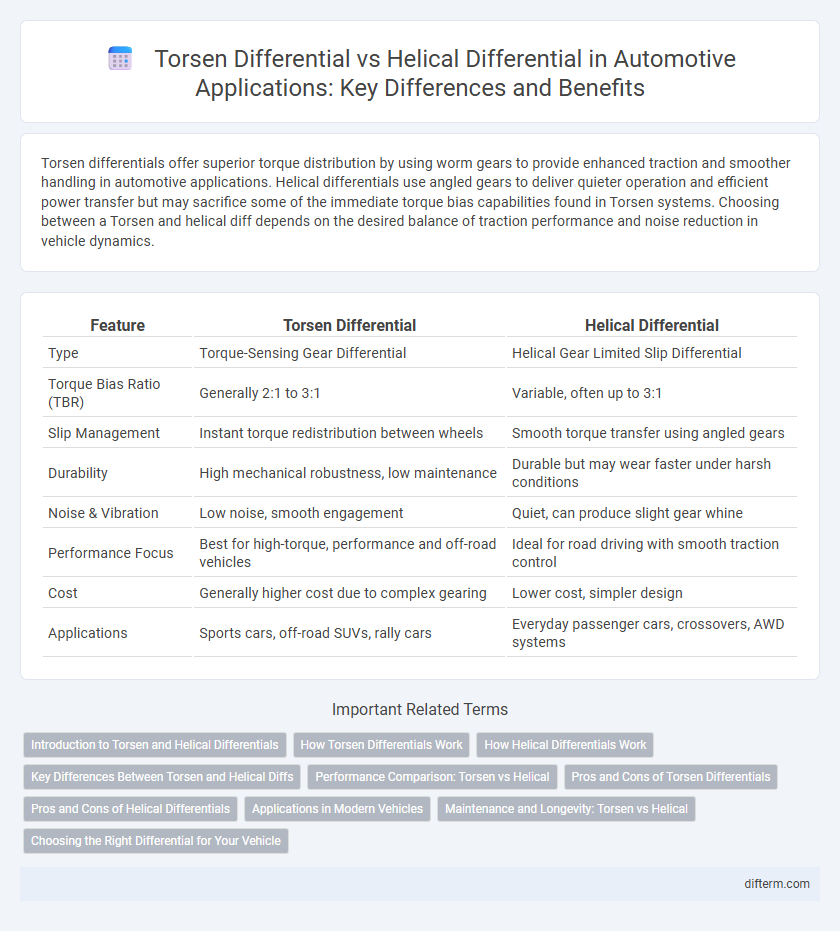

| Feature | Torsen Differential | Helical Differential |

|---|---|---|

| Type | Torque-Sensing Gear Differential | Helical Gear Limited Slip Differential |

| Torque Bias Ratio (TBR) | Generally 2:1 to 3:1 | Variable, often up to 3:1 |

| Slip Management | Instant torque redistribution between wheels | Smooth torque transfer using angled gears |

| Durability | High mechanical robustness, low maintenance | Durable but may wear faster under harsh conditions |

| Noise & Vibration | Low noise, smooth engagement | Quiet, can produce slight gear whine |

| Performance Focus | Best for high-torque, performance and off-road vehicles | Ideal for road driving with smooth traction control |

| Cost | Generally higher cost due to complex gearing | Lower cost, simpler design |

| Applications | Sports cars, off-road SUVs, rally cars | Everyday passenger cars, crossovers, AWD systems |

Introduction to Torsen and Helical Differentials

Torsen differentials use a worm gear mechanism to provide torque-sensing capabilities, enabling precise power distribution between wheels for enhanced traction and cornering. Helical differentials rely on angled helical gears that create a smooth torque bias through friction, improving stability on varying road surfaces. Both designs are integral in all-wheel-drive systems, but Torsen offers quicker response times, whereas helical diffs focus on smoother operation.

How Torsen Differentials Work

Torsen differentials use helical gears to distribute torque between wheels based on traction, relying on the differential's internal worm gears that automatically bias power to the wheel with more grip without electronic input. Unlike traditional helical differentials that primarily split torque evenly, Torsen differentials dynamically adjust torque transfer real-time, enhancing cornering performance and stability. This mechanical torque-sensing mechanism improves vehicle handling by reducing wheel slip and maximizing traction on uneven or slippery surfaces.

How Helical Differentials Work

Helical differentials use angled helical gears to transfer torque smoothly between wheels, providing continuous and gradual power distribution without sudden engagement. This design enhances traction by allowing torque to flow to the wheel with the most grip, improving vehicle stability on uneven surfaces. Their quiet operation and low maintenance make helical differentials ideal for modern automotive applications requiring efficient and reliable performance.

Key Differences Between Torsen and Helical Diffs

Torsen differentials utilize worm gears to provide torque-sensing capabilities, delivering variable torque distribution for improved traction and handling. Helical differentials rely on angled helical gears, offering smoother engagement and quieter operation but less precise torque biasing compared to Torsen. Key differences include Torsen's higher torque bias ratio and faster response in torque transfer, making it ideal for performance vehicles, while helical diffs prioritize durability and cost-effectiveness in everyday driving conditions.

Performance Comparison: Torsen vs Helical

Torsen differentials deliver superior torque biasing and faster response times compared to helical differentials, enhancing vehicle stability and traction under dynamic driving conditions. The worm gear design in Torsen diffs provides a more predictable power distribution on slippery surfaces, improving cornering performance and reducing wheel slip. Helical differentials, while smoother and quieter, generally offer less aggressive torque transfer, leading to moderate performance in off-road or high-performance scenarios.

Pros and Cons of Torsen Differentials

Torsen differentials offer superior torque distribution and enhanced traction by mechanically sensing torque differences, providing immediate power transfer to the wheel with more grip without electronic intervention. Their robust design reduces wheel slip and improves handling, especially in performance and off-road vehicles, but they tend to be heavier, more complex, and costlier than helical differentials. However, Torsen diffs may be less effective in low-traction scenarios such as ice or mud where both wheels lose grip, unlike some helical designs that perform more predictably under those conditions.

Pros and Cons of Helical Differentials

Helical differentials offer smooth and quiet operation with improved traction by distributing torque evenly between wheels, making them ideal for on-road performance and moderate off-road conditions. However, they can generate more internal friction compared to Torsen differentials, leading to slight efficiency losses and increased wear over time. Their reliance on helical gears means reduced effectiveness in extreme low-traction scenarios where torque biasing is critical.

Applications in Modern Vehicles

Torsen differentials are widely used in sports cars and high-performance vehicles due to their ability to provide precise torque distribution and enhanced traction on varying road surfaces. Helical differentials, commonly found in everyday passenger cars and SUVs, offer smooth, quiet operation with reliable torque transfer suitable for all-weather conditions. Modern all-wheel-drive systems often combine these differential types to optimize vehicle stability, handling, and fuel efficiency.

Maintenance and Longevity: Torsen vs Helical

Torsen differentials typically offer superior longevity and require less frequent maintenance due to their robust gear-based design, which minimizes wear under high torque conditions. Helical differentials, while smoother in operation, often demand more regular inspection and maintenance to address potential issues with their worm and spur gear interactions. Choosing a Torsen diff can reduce long-term servicing costs and downtime, making it a preferred option in performance and off-road automotive applications.

Choosing the Right Differential for Your Vehicle

Choosing between a Torsen differential and a helical differential depends on your vehicle's performance needs and driving conditions. Torsen differentials excel in delivering torque biasing with rapid response, making them ideal for high-performance sports cars requiring superior traction and handling on varied road surfaces. Helical differentials offer smoother, quieter operation and better durability in everyday driving scenarios, making them suitable for daily-driven vehicles prioritizing comfort and reliability.

Torsen diff vs helical diff Infographic

difterm.com

difterm.com