Speed density systems estimate engine airflow based on manifold pressure and air temperature, providing reliable performance without direct airflow measurement. Mass airflow sensors measure the actual volume of air entering the engine, offering precise fuel delivery and improved efficiency. In automotive applications, mass airflow generally delivers better accuracy, while speed density is valued for simplicity and cost-effectiveness.

Table of Comparison

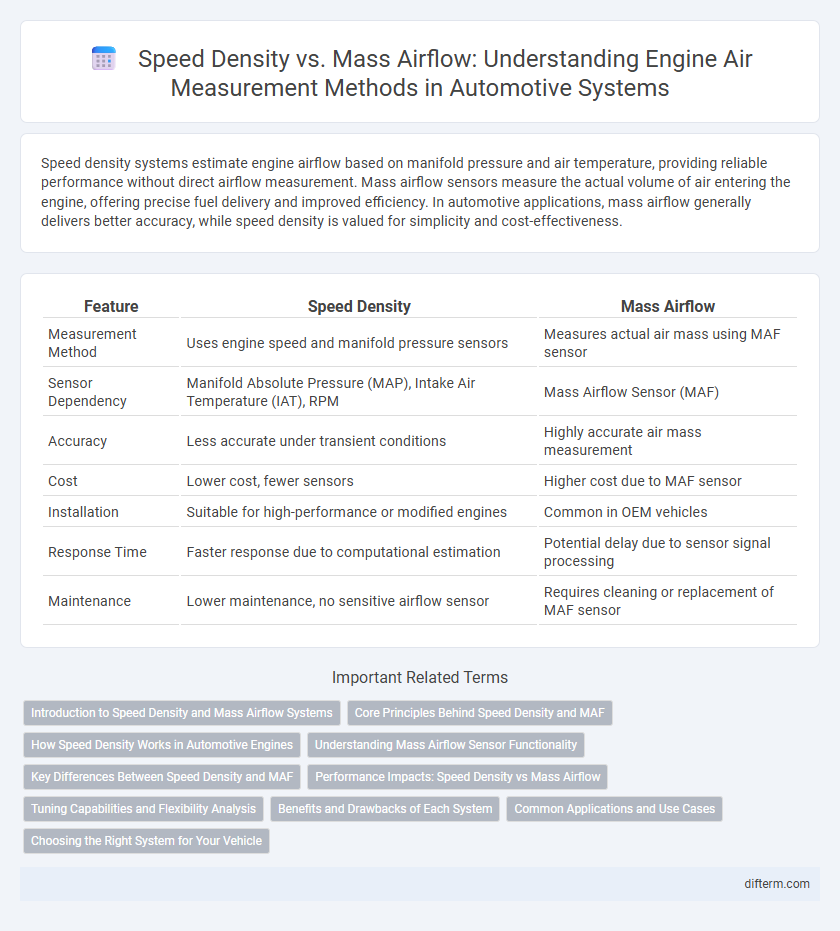

| Feature | Speed Density | Mass Airflow |

|---|---|---|

| Measurement Method | Uses engine speed and manifold pressure sensors | Measures actual air mass using MAF sensor |

| Sensor Dependency | Manifold Absolute Pressure (MAP), Intake Air Temperature (IAT), RPM | Mass Airflow Sensor (MAF) |

| Accuracy | Less accurate under transient conditions | Highly accurate air mass measurement |

| Cost | Lower cost, fewer sensors | Higher cost due to MAF sensor |

| Installation | Suitable for high-performance or modified engines | Common in OEM vehicles |

| Response Time | Faster response due to computational estimation | Potential delay due to sensor signal processing |

| Maintenance | Lower maintenance, no sensitive airflow sensor | Requires cleaning or replacement of MAF sensor |

Introduction to Speed Density and Mass Airflow Systems

Speed density and mass airflow systems are two primary methods for measuring engine air intake to optimize fuel injection and ignition timing. Speed density relies on engine speed and manifold absolute pressure (MAP) sensor data to estimate air mass, while mass airflow systems use a dedicated sensor to directly measure the incoming air volume. Understanding the differences between these systems is crucial for tuning and diagnosing modern automotive engine management.

Core Principles Behind Speed Density and MAF

Speed Density systems calculate engine airflow based on manifold pressure, intake air temperature, and engine speed using volumetric efficiency tables, providing precise fuel delivery without a physical airflow sensor. Mass Airflow (MAF) sensors measure the actual volume and density of incoming air, directly capturing real-time airflow data for accurate fuel calculation. Both methods rely on airflow measurement principles, with Speed Density emphasizing calculated engine parameters and MAF focusing on direct airflow measurement for fueling accuracy.

How Speed Density Works in Automotive Engines

Speed density calculates engine airflow by using manifold absolute pressure (MAP), intake air temperature (IAT), and engine speed (RPM) to estimate air mass entering the engine, enabling precise fuel delivery in real-time. This method relies on predefined volumetric efficiency tables and engine displacement parameters, allowing the ECU to determine the proper air density without a direct airflow sensor. Speed density systems are preferred in performance tuning and turbocharged applications due to their responsiveness and adaptability to varying pressure conditions.

Understanding Mass Airflow Sensor Functionality

The mass airflow (MAF) sensor measures the actual amount of air entering the engine, providing precise data for the engine control unit (ECU) to optimize fuel injection and maintain ideal air-fuel ratios. In contrast, the speed density system estimates air intake based on manifold pressure and engine speed without direct airflow measurement, often resulting in less accuracy under varying conditions. Understanding MAF sensor functionality helps improve engine performance, fuel efficiency, and emissions control by delivering real-time airflow data critical for modern automotive engines.

Key Differences Between Speed Density and MAF

Speed Density relies on manifold absolute pressure (MAP), intake air temperature, and RPM to calculate engine airflow, providing quick response in transient conditions without a physical sensor. Mass Airflow (MAF) uses a sensor to directly measure the mass of incoming air, offering precise airflow data that adapts to modifications like forced induction or intake changes. Speed Density is less affected by sensor contamination and often preferred in high-performance tuning, while MAF provides more accurate fueling in stock applications due to real-time airflow measurement.

Performance Impacts: Speed Density vs Mass Airflow

Speed Density systems use manifold pressure and intake air temperature to calculate airflow, providing quicker response and better tuning flexibility, which enhances throttle response and overall engine performance. Mass Airflow sensors measure the actual volume of air entering the engine, offering accuracy in varying conditions but potentially causing lag under rapid throttle changes due to sensor processing time. For high-performance applications, Speed Density offers improved transient response and adaptability, while Mass Airflow ensures reliable data for consistent power output across diverse environments.

Tuning Capabilities and Flexibility Analysis

Speed density tuning leverages manifold absolute pressure and intake air temperature data to calculate engine airflow, enabling precise fuel delivery adjustments without relying on external airflow sensors, which enhances tuning flexibility for various engine modifications. Mass airflow (MAF) tuning uses real-time airflow measurements, providing accurate fuel mapping across a wide range of operating conditions but may be less adaptable when installing aftermarket intakes or forced induction systems. The choice between speed density and MAF tuning significantly impacts calibration strategies, with speed density offering greater adaptability for custom setups and MAF delivering consistent accuracy under stock-like conditions.

Benefits and Drawbacks of Each System

Speed density systems use manifold absolute pressure (MAP) sensors and intake air temperature data to calculate engine airflow, offering benefits like cost-effectiveness, simplicity, and fewer moving parts, which enhance system reliability. Mass airflow (MAF) systems directly measure the volume of air entering the engine using a MAF sensor, providing greater accuracy in varying environmental conditions and improved fuel management under dynamic driving scenarios. However, speed density systems may suffer from less precise airflow estimates under rapid throttle changes or engine modifications, while MAF sensors can be more expensive, sensitive to contamination, and prone to calibration drift over time.

Common Applications and Use Cases

Speed density and mass airflow are two critical methods for determining engine load in automotive engine management systems. Speed density is commonly used in turbocharged and high-performance engines due to its accuracy in varying atmospheric conditions and its reliance on manifold pressure and engine speed sensors. Mass airflow sensors are frequently employed in naturally aspirated engines where straightforward, direct measurement of incoming air improves fuel injection precision and emissions control.

Choosing the Right System for Your Vehicle

Selecting between speed density and mass airflow systems depends on your vehicle's specific performance needs and operating conditions. Speed density systems use manifold absolute pressure and engine RPM to calculate air intake, offering advantages in high-performance tuning and reliability under extreme conditions. Mass airflow sensors provide precise real-time measurement of incoming air, delivering improved fuel efficiency and smoother throttle response, making them ideal for street-driven vehicles seeking balanced performance.

speed density vs mass airflow Infographic

difterm.com

difterm.com