The break-in period for automotive pets, such as driving aids or electronic accessories installed in vehicles, ensures optimal performance and longevity by allowing components to adjust gradually under controlled conditions. Choosing devices that require no break-in period offers immediate full functionality and convenience, reducing downtime and eliminating the need for special handling during initial use. Understanding the difference helps vehicle owners select products that best fit their driving habits and maintenance preferences.

Table of Comparison

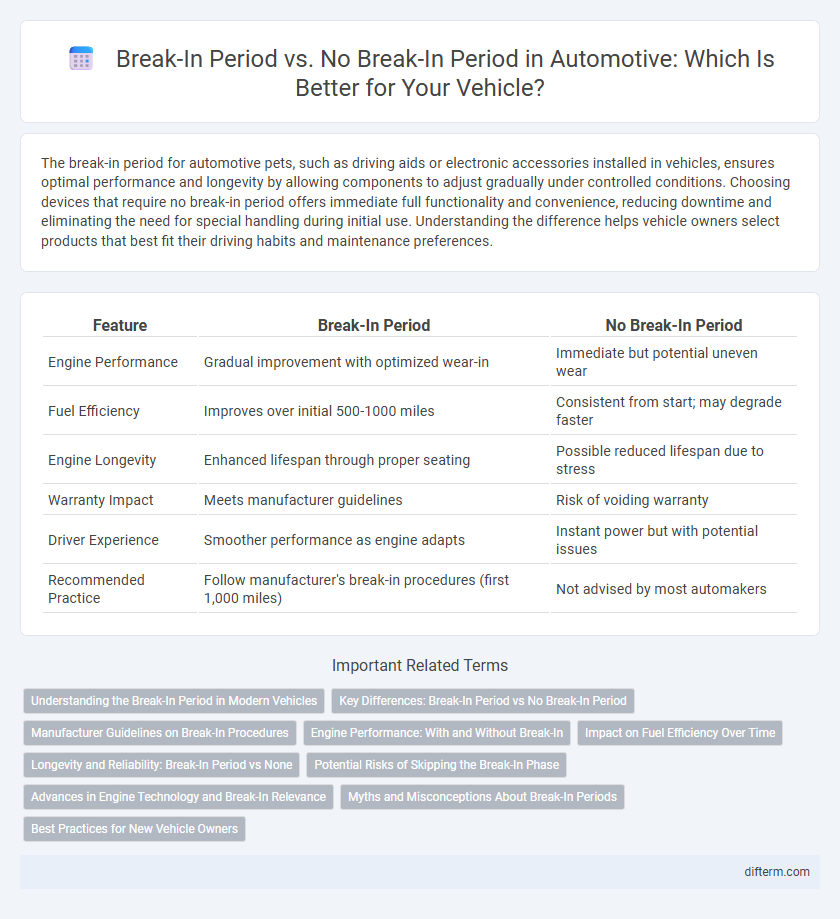

| Feature | Break-In Period | No Break-In Period |

|---|---|---|

| Engine Performance | Gradual improvement with optimized wear-in | Immediate but potential uneven wear |

| Fuel Efficiency | Improves over initial 500-1000 miles | Consistent from start; may degrade faster |

| Engine Longevity | Enhanced lifespan through proper seating | Possible reduced lifespan due to stress |

| Warranty Impact | Meets manufacturer guidelines | Risk of voiding warranty |

| Driver Experience | Smoother performance as engine adapts | Instant power but with potential issues |

| Recommended Practice | Follow manufacturer's break-in procedures (first 1,000 miles) | Not advised by most automakers |

Understanding the Break-In Period in Modern Vehicles

The break-in period in modern vehicles is designed to ensure optimal engine performance and longevity by allowing components such as piston rings and cylinder walls to properly seat under controlled conditions. Skipping this process can lead to increased wear, reduced fuel efficiency, and potential long-term engine damage despite advancements in materials and manufacturing technologies. Understanding manufacturer-specific guidelines for break-in periods helps maintain warranty validity and maximizes engine durability.

Key Differences: Break-In Period vs No Break-In Period

The break-in period involves gradually increasing engine load and speed to allow components such as piston rings and cylinder walls to properly seat, reducing wear and enhancing long-term performance. In contrast, a no break-in period assumes modern manufacturing tolerances and materials eliminate the need for gradual use, enabling immediate full performance but potentially risking uneven seating and early component wear. Understanding these key differences helps optimize engine longevity, warranty compliance, and initial performance based on vehicle design and manufacturer recommendations.

Manufacturer Guidelines on Break-In Procedures

Manufacturer guidelines on break-in procedures emphasize the importance of controlled driving conditions during the initial 1,000 miles to ensure optimal engine performance and longevity. Some manufacturers recommend avoiding full throttle, high RPMs, and heavy loads to allow engine components to properly seat and minimize wear. Emerging trends toward no break-in periods reflect advancements in manufacturing precision and lubricants, but adherence to specific manufacturer break-in instructions remains critical for warranty compliance and vehicle reliability.

Engine Performance: With and Without Break-In

Engines with a proper break-in period typically achieve optimal piston ring seating, leading to improved compression and reduced oil consumption, which enhances overall engine performance and longevity. Without a break-in period, engines may experience suboptimal sealing and increased wear, resulting in decreased fuel efficiency, lower power output, and higher emission levels. Modern engine designs and advanced materials sometimes allow for reduced or no break-in requirements, but controlled initial operating conditions remain crucial for maximizing engine durability and performance.

Impact on Fuel Efficiency Over Time

A proper break-in period for new vehicles improves fuel efficiency by allowing engine components to wear in gradually, optimizing combustion and reducing friction. Vehicles without a break-in period often experience higher initial fuel consumption due to incomplete sealing of engine parts and uneven wear. Over time, engines subjected to a break-in period maintain better fuel economy and lower emissions compared to those without controlled usage during early operation.

Longevity and Reliability: Break-In Period vs None

Engines subjected to a proper break-in period typically exhibit enhanced longevity and improved reliability due to the gradual settling of components and the formation of optimal wear patterns. Conversely, skipping the break-in can lead to premature wear and potential mechanical failures, negatively impacting the overall lifespan of the vehicle. Manufacturers often recommend break-in protocols to ensure consistent engine performance and durability over time.

Potential Risks of Skipping the Break-In Phase

Skipping the break-in period in automotive engines can lead to increased wear and tear due to insufficient proper seating of piston rings and cylinder walls. This practice may result in reduced engine efficiency, higher oil consumption, and a greater likelihood of premature engine failure. Proper break-in ensures optimal engine longevity and performance by allowing components to bed in under controlled conditions.

Advances in Engine Technology and Break-In Relevance

Advances in engine technology, such as improved machining precision, higher-quality materials, and enhanced manufacturing processes, have significantly reduced the necessity of traditional break-in periods for new vehicles. Modern engines employ computer-controlled fuel injection and adaptive engine management systems that optimize performance from the first start, minimizing wear and ensuring longevity without extensive initial conditioning. Despite these technological improvements, some manufacturers still recommend a controlled break-in to ensure optimal sealing of piston rings and longevity under specific operating conditions.

Myths and Misconceptions About Break-In Periods

The break-in period in automotive engines is often surrounded by myths suggesting immediate high-performance driving causes damage, yet modern engines are designed with precision manufacturing that reduces this necessity. Many misconceptions claim neglecting the break-in period leads to engine failure, but current materials and production techniques ensure engines can endure varied driving conditions from the start. Scientific studies and manufacturer guidelines emphasize proper maintenance over rigid break-in protocols for long-term engine reliability.

Best Practices for New Vehicle Owners

New vehicle owners should follow the manufacturer's recommended break-in period, typically spanning the first 1,000 miles, to ensure optimal engine performance and longevity. Proper break-in practices include varying engine speeds, avoiding full-throttle acceleration, and refraining from towing heavy loads to allow engine components to settle correctly. Ignoring the break-in period can lead to premature wear, reduced fuel efficiency, and potential engine damage, impacting the vehicle's resale value and reliability.

break-in period vs no break-in period Infographic

difterm.com

difterm.com