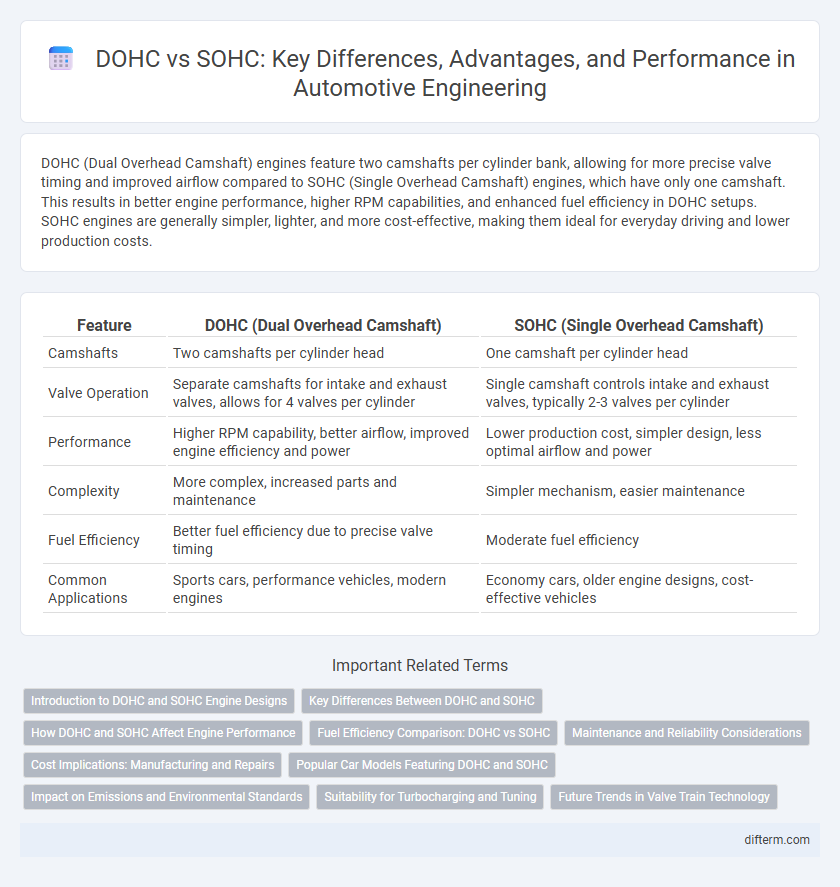

DOHC (Dual Overhead Camshaft) engines feature two camshafts per cylinder bank, allowing for more precise valve timing and improved airflow compared to SOHC (Single Overhead Camshaft) engines, which have only one camshaft. This results in better engine performance, higher RPM capabilities, and enhanced fuel efficiency in DOHC setups. SOHC engines are generally simpler, lighter, and more cost-effective, making them ideal for everyday driving and lower production costs.

Table of Comparison

| Feature | DOHC (Dual Overhead Camshaft) | SOHC (Single Overhead Camshaft) |

|---|---|---|

| Camshafts | Two camshafts per cylinder head | One camshaft per cylinder head |

| Valve Operation | Separate camshafts for intake and exhaust valves, allows for 4 valves per cylinder | Single camshaft controls intake and exhaust valves, typically 2-3 valves per cylinder |

| Performance | Higher RPM capability, better airflow, improved engine efficiency and power | Lower production cost, simpler design, less optimal airflow and power |

| Complexity | More complex, increased parts and maintenance | Simpler mechanism, easier maintenance |

| Fuel Efficiency | Better fuel efficiency due to precise valve timing | Moderate fuel efficiency |

| Common Applications | Sports cars, performance vehicles, modern engines | Economy cars, older engine designs, cost-effective vehicles |

Introduction to DOHC and SOHC Engine Designs

Dual Overhead Camshaft (DOHC) engines feature two camshafts per cylinder head, allowing independent control of intake and exhaust valves, enhancing engine performance and efficiency. Single Overhead Camshaft (SOHC) engines use a single camshaft to operate both intake and exhaust valves, offering simpler design and reduced manufacturing costs. DOHC designs typically provide higher power output and better valve timing precision, while SOHC engines balance performance with compactness and lower complexity.

Key Differences Between DOHC and SOHC

DOHC (Dual Overhead Camshaft) engines feature two camshafts per cylinder head, enabling separate control of intake and exhaust valves, which enhances valve timing precision and improves high RPM performance. SOHC (Single Overhead Camshaft) engines utilize a single camshaft to operate both intake and exhaust valves, resulting in simpler design, reduced manufacturing costs, and typically better low to mid-range torque delivery. The primary distinctions lie in valve control complexity, engine efficiency, and performance characteristics tailored for different driving demands.

How DOHC and SOHC Affect Engine Performance

DOHC (Dual Overhead Camshaft) engines improve engine performance by allowing more precise control of intake and exhaust valves, leading to increased airflow and higher RPM capabilities compared to SOHC (Single Overhead Camshaft) engines. SOHC engines typically offer simpler design and lower manufacturing costs but may sacrifice some power and efficiency due to less optimal valve timing. The enhanced valve timing and greater valve area in DOHC configurations contribute to better fuel combustion and overall higher engine output.

Fuel Efficiency Comparison: DOHC vs SOHC

Dual Overhead Camshaft (DOHC) engines provide more precise valve timing control than Single Overhead Camshaft (SOHC) designs, enhancing combustion efficiency and improving fuel economy. SOHC engines typically have fewer moving parts, resulting in lower internal friction and slightly better fuel efficiency at low to moderate speeds. DOHC configurations excel at higher RPMs with optimized airflow, yielding better fuel efficiency during aggressive driving conditions and variable valve timing systems.

Maintenance and Reliability Considerations

DOHC engines typically require more precise maintenance due to their complex valve train and additional camshafts, which can increase the risk of timing chain or belt issues if not regularly serviced. SOHC engines, with a simpler design, often present fewer maintenance challenges and tend to offer greater long-term reliability, especially in high-mileage scenarios. Regular oil changes and valve adjustments remain critical for both designs to ensure optimal performance and durability.

Cost Implications: Manufacturing and Repairs

DOHC (Double Overhead Camshaft) engines typically incur higher manufacturing costs due to their complex design involving two camshafts per cylinder bank and more precise timing mechanisms. Repair expenses tend to be greater compared to SOHC (Single Overhead Camshaft) engines because the additional components and tighter tolerances increase labor time and parts replacement costs. SOHC engines offer a cost-effective solution for manufacturers and consumers seeking simpler maintenance and lower initial production expenses.

Popular Car Models Featuring DOHC and SOHC

Popular car models featuring DOHC engines include the Honda Civic, Toyota Corolla, and Ford Mustang, valued for their higher performance and efficiency. SOHC engines are commonly found in models like the Hyundai Elantra, Nissan Sentra, and early-generation Volkswagen Jetta, offering simpler design and cost-effective maintenance. The choice between DOHC and SOHC in popular vehicles reflects a balance between power output and engine complexity preferred by manufacturers and consumers.

Impact on Emissions and Environmental Standards

DOHC (Dual Overhead Camshaft) engines typically offer more precise valve timing control compared to SOHC (Single Overhead Camshaft) designs, resulting in improved combustion efficiency and reduced emissions of pollutants such as NOx and CO. Enhanced airflow management in DOHC engines contributes to cleaner exhaust output, aiding compliance with stringent environmental standards like Euro 6 and EPA Tier 3 regulations. SOHC engines generally produce higher emissions due to less optimized valve operation, making DOHC preferred for manufacturers aiming to meet modern emissions targets.

Suitability for Turbocharging and Tuning

DOHC (Dual Overhead Camshaft) engines offer superior valve control and higher RPM potential, making them more suitable for turbocharging and performance tuning compared to SOHC (Single Overhead Camshaft) engines. The independent camshafts allow precise timing adjustments for intake and exhaust valves, optimizing airflow and boost efficiency under forced induction. Tuning flexibility is enhanced in DOHC setups due to better valve timing control, resulting in improved power gains and responsiveness in turbocharged applications.

Future Trends in Valve Train Technology

Future trends in valve train technology focus on increasing efficiency and performance, with DOHC (Double Overhead Camshaft) systems gaining prominence due to their ability to support variable valve timing and multi-valve configurations. Advancements in electronic valve actuation and camless valve technology promise precise control over valve operation, reducing emissions and improving fuel economy compared to traditional SOHC (Single Overhead Camshaft) designs. Integration of lightweight materials and smart sensors is set to further enhance durability and real-time engine optimization in next-generation automotive engines.

DOHC vs SOHC Infographic

difterm.com

difterm.com