The Torsen differential offers precise torque distribution through its gear-based system, enhancing traction and stability without the need for electronic intervention. In contrast, clutch-type differentials rely on friction plates to modulate torque, which can wear over time and may require maintenance. Torsen differentials generally provide smoother performance and durability, making them ideal for high-demand automotive applications.

Table of Comparison

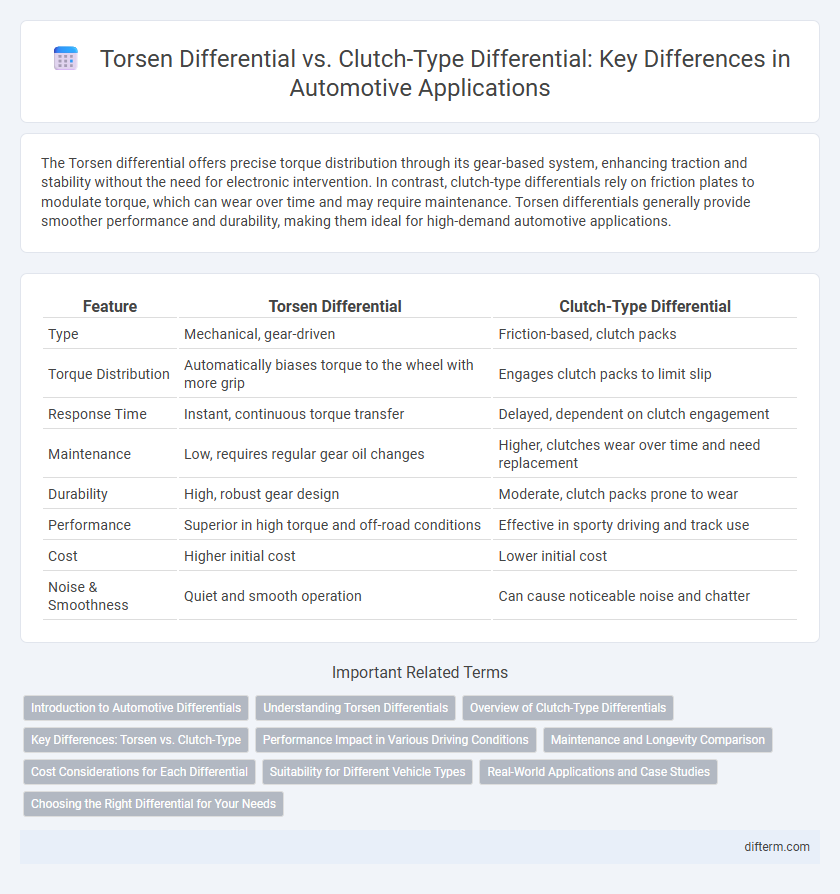

| Feature | Torsen Differential | Clutch-Type Differential |

|---|---|---|

| Type | Mechanical, gear-driven | Friction-based, clutch packs |

| Torque Distribution | Automatically biases torque to the wheel with more grip | Engages clutch packs to limit slip |

| Response Time | Instant, continuous torque transfer | Delayed, dependent on clutch engagement |

| Maintenance | Low, requires regular gear oil changes | Higher, clutches wear over time and need replacement |

| Durability | High, robust gear design | Moderate, clutch packs prone to wear |

| Performance | Superior in high torque and off-road conditions | Effective in sporty driving and track use |

| Cost | Higher initial cost | Lower initial cost |

| Noise & Smoothness | Quiet and smooth operation | Can cause noticeable noise and chatter |

Introduction to Automotive Differentials

Torsen differentials use worm gears to distribute torque based on traction, providing smooth and automatic torque transfer between wheels, enhancing stability and performance in various driving conditions. Clutch-type differentials rely on friction clutches to control wheel slippage, allowing for adjustable torque distribution but often requiring maintenance due to wear. In automotive applications, choosing between Torsen and clutch-type differentials depends on factors like vehicle usage, desired handling characteristics, and maintenance preferences.

Understanding Torsen Differentials

Torsen differentials utilize helical gears to distribute torque smoothly between wheels, enhancing traction without the need for electronic intervention. Unlike clutch-type differentials, which rely on friction plates that can wear over time, Torsen differentials provide immediate torque transfer and greater durability under high-stress driving conditions. This mechanical advantage makes Torsen differentials ideal for performance and off-road vehicles requiring consistent grip and stability.

Overview of Clutch-Type Differentials

Clutch-type differentials use a set of friction plates to distribute torque between wheels, offering controlled slip and improved traction during cornering and low-traction conditions. These differentials are commonly found in performance and off-road vehicles due to their ability to adjust torque dynamically based on wheel slip. Compared to Torsen differentials, clutch-type systems provide tunable locking characteristics and responsiveness suited for variable driving environments.

Key Differences: Torsen vs. Clutch-Type

Torsen differentials use helical gears to provide continuous, smooth torque distribution between wheels based on traction, offering superior reliability and low maintenance compared to clutch-type differentials. Clutch-type differentials rely on friction plates to modulate torque, allowing for adjustable locking but requiring regular maintenance due to wear and heat buildup. The mechanical engagement of Torsen units ensures faster response and durability, making them ideal for performance and off-road vehicles, while clutch-type differentials offer customizable traction control suited for racing and street applications.

Performance Impact in Various Driving Conditions

Torsen differentials provide superior torque distribution and improved traction in variable driving conditions by instantly transferring power to the wheel with the most grip, enhancing stability and cornering performance. Clutch-type differentials rely on friction plates to control wheel slip, offering adjustable locking but potentially less precise torque split and increased wear under aggressive driving. In off-road or slippery environments, Torsen differentials maintain consistent power delivery, while clutch-type systems may require frequent adjustments to optimize performance.

Maintenance and Longevity Comparison

Torsen differentials require minimal maintenance due to their mechanical design, which relies on gears rather than friction plates, resulting in increased longevity and consistent performance over time. Clutch-type differentials demand regular inspection and replacement of worn clutch plates to maintain optimal functionality, often leading to higher maintenance costs and shorter service intervals. The robust, gear-driven construction of Torsen differentials typically extends their lifespan beyond that of clutch-type systems in automotive applications.

Cost Considerations for Each Differential

Torsen differentials typically incur higher initial costs due to their complex internal gearing and precision manufacturing. Clutch-type differentials tend to be more affordable upfront, with simpler mechanical designs and widely available components. Long-term maintenance expenses may be higher for clutch systems, as frequent clutch pack replacements are often necessary, whereas Torsen differentials generally require less maintenance over time.

Suitability for Different Vehicle Types

Torsen differentials excel in high-performance and off-road vehicles due to their ability to provide seamless torque distribution between wheels without electronic intervention. Clutch-type differentials suit everyday passenger cars and lightweight sports vehicles by offering controlled slip and improved traction under varying road conditions. Torsen's mechanical design ensures durability and consistent performance in rugged environments, while clutch-type units offer cost-effective adaptability for urban and mixed driving scenarios.

Real-World Applications and Case Studies

Torsen differentials excel in real-world applications such as performance sports cars and off-road vehicles, providing seamless torque distribution and enhanced traction without driver intervention. Clutch-type differentials are prevalent in vehicles requiring adjustable traction control, including rally cars and torque vectoring systems, where variable lockup improves handling during aggressive cornering. Case studies from manufacturers like Audi's Quattro system demonstrate Torsen's reliability in high-speed stability, while Subaru's clutch-type differentials highlight benefits in adaptable traction under diverse driving conditions.

Choosing the Right Differential for Your Needs

Torsen differentials provide superior torque distribution by mechanically transferring power between wheels based on traction, ideal for high-performance and off-road driving where consistent grip is crucial. Clutch-type differentials use friction plates to limit wheel slip, offering more customizable lock settings suitable for varied driving conditions and easier maintenance. Selecting the right differential depends on your driving style, terrain, and need for responsiveness versus adaptability in torque distribution.

Torsen differential vs clutch-type differential Infographic

difterm.com

difterm.com