The monocoque chassis integrates the body and frame into a single unit, enhancing vehicle rigidity and reducing weight for improved fuel efficiency and handling in automotive pet designs. In contrast, the ladder frame consists of two longitudinal rails connected by cross members, offering superior strength for off-road durability and heavy-duty applications but tends to be heavier and less aerodynamic. Choosing between the two depends on priorities such as performance, safety, and intended vehicle use in the pet automotive sector.

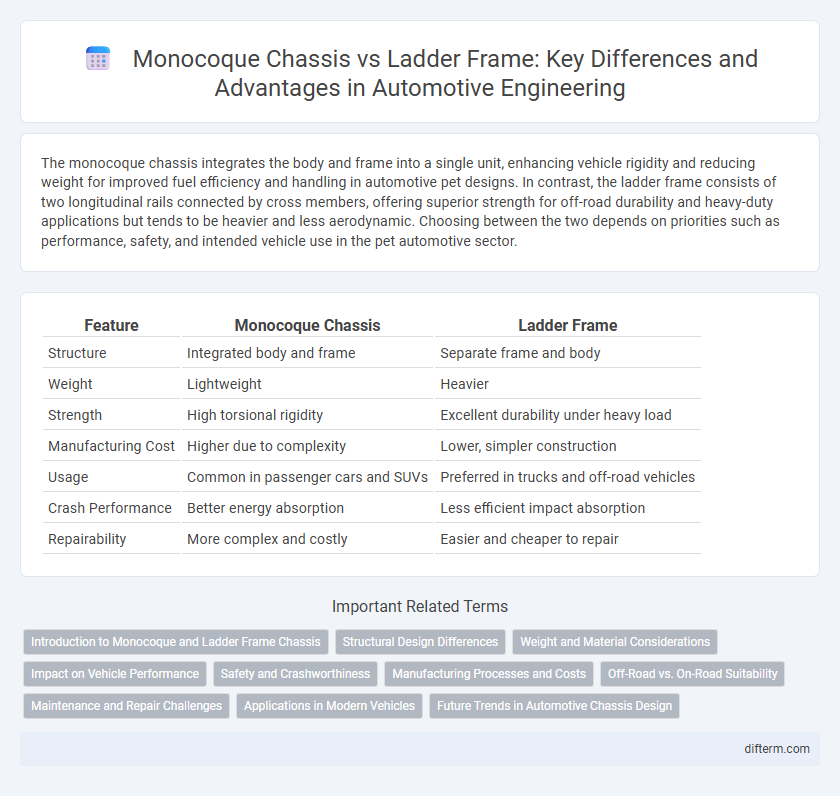

Table of Comparison

| Feature | Monocoque Chassis | Ladder Frame |

|---|---|---|

| Structure | Integrated body and frame | Separate frame and body |

| Weight | Lightweight | Heavier |

| Strength | High torsional rigidity | Excellent durability under heavy load |

| Manufacturing Cost | Higher due to complexity | Lower, simpler construction |

| Usage | Common in passenger cars and SUVs | Preferred in trucks and off-road vehicles |

| Crash Performance | Better energy absorption | Less efficient impact absorption |

| Repairability | More complex and costly | Easier and cheaper to repair |

Introduction to Monocoque and Ladder Frame Chassis

Monocoque chassis integrates the body and frame into a single unit, enhancing structural rigidity while reducing weight, which improves fuel efficiency and handling in modern vehicles. Ladder frame chassis consists of a strong, rectangular steel frame that supports the vehicle's body and components, offering durability and ease of repair, making it ideal for trucks and off-road applications. Understanding these fundamental designs helps in selecting the appropriate chassis based on vehicle usage, performance needs, and manufacturing costs.

Structural Design Differences

Monocoque chassis integrates the vehicle's body and frame into a single unified structure, enhancing rigidity and reducing weight for improved handling and fuel efficiency. Ladder frame consists of two parallel beams connected by cross members, providing robust support ideal for heavy-duty and off-road applications due to its superior durability and ease of repair. Structural differences impact vehicle performance, with monocoque offering better crash energy absorption while ladder frame excels in load-bearing capacity and customization.

Weight and Material Considerations

Monocoque chassis designs typically use lightweight materials such as aluminum or carbon fiber composites, resulting in significant weight reduction compared to traditional ladder frames constructed from steel. This weight advantage enhances fuel efficiency and handling dynamics in vehicles employing monocoque construction. Ladder frames provide superior durability for heavy-duty applications but incur higher mass, impacting overall vehicle weight and performance.

Impact on Vehicle Performance

Monocoque chassis offers superior rigidity and reduced weight compared to ladder frames, enhancing handling, acceleration, and fuel efficiency in vehicles. The integrated structure distributes stress evenly, improving crash safety and ride quality. In contrast, ladder frames provide greater durability and ease of repair, making them preferable for heavy-duty and off-road applications despite their higher weight and reduced agility.

Safety and Crashworthiness

Monocoque chassis offers superior safety and crashworthiness by distributing impact forces across the entire body structure, reducing injury risk. Ladder frame designs concentrate impact forces on the frame, often leading to higher occupant injury potential during collisions. Advanced materials and engineering in monocoque structures enhance energy absorption and structural integrity compared to traditional ladder frames.

Manufacturing Processes and Costs

Monocoque chassis manufacturing involves advanced stamping and welding techniques that integrate the body and frame into a single unit, resulting in lower material usage and reduced assembly time compared to ladder frame construction. Ladder frame chassis require separate fabrication of the frame and body, involving more labor-intensive processes such as riveting and bolting, which increase manufacturing complexity and cost. Overall, monocoque designs benefit from automation and economies of scale, leading to cost efficiencies, while ladder frames incur higher expenses due to material weight and assembly labor.

Off-Road vs. On-Road Suitability

Monocoque chassis offers superior rigidity and lightweight construction, making it ideal for on-road vehicles with enhanced handling and fuel efficiency. Ladder frame chassis provides exceptional durability and flexibility, perfect for off-road conditions requiring robust impact resistance and easier repairability. Off-road vehicles benefit from ladder frames due to their ability to absorb rough terrain stresses, while monocoque designs excel in paved environments where precision and comfort are prioritized.

Maintenance and Repair Challenges

Monocoque chassis models generally present higher maintenance and repair complexity due to their integrated structure, which often requires specialized tools and expertise for bodywork and frame repairs. Ladder frame vehicles allow easier access to individual components and simpler frame repairs, typically resulting in lower repair costs and reduced downtime. Repair professionals frequently recommend ladder frames for heavy-duty use where frequent maintenance is expected, contrasting with monocoque vehicles that excel in weight reduction and structural stiffness but demand meticulous repair processes.

Applications in Modern Vehicles

Monocoque chassis dominate passenger cars and electric vehicles due to their lightweight structure and enhanced crash safety, improving fuel efficiency and handling. Ladder frames remain prevalent in trucks, SUVs, and off-road vehicles for their superior strength and durability under heavy loads and rough terrain. Modern automotive design increasingly blends monocoque structures with ladder frame elements in crossover SUVs to balance comfort and robustness.

Future Trends in Automotive Chassis Design

Future trends in automotive chassis design emphasize lightweight monocoque structures integrated with advanced composite materials for enhanced rigidity and crash safety. Innovations in ladder frame development focus on modularity and hybrid architectures to support electric and autonomous vehicle platforms. Increasing adoption of smart sensor integration and adaptive suspension systems drives performance optimization and energy efficiency across next-generation chassis frameworks.

monocoque chassis vs ladder frame Infographic

difterm.com

difterm.com