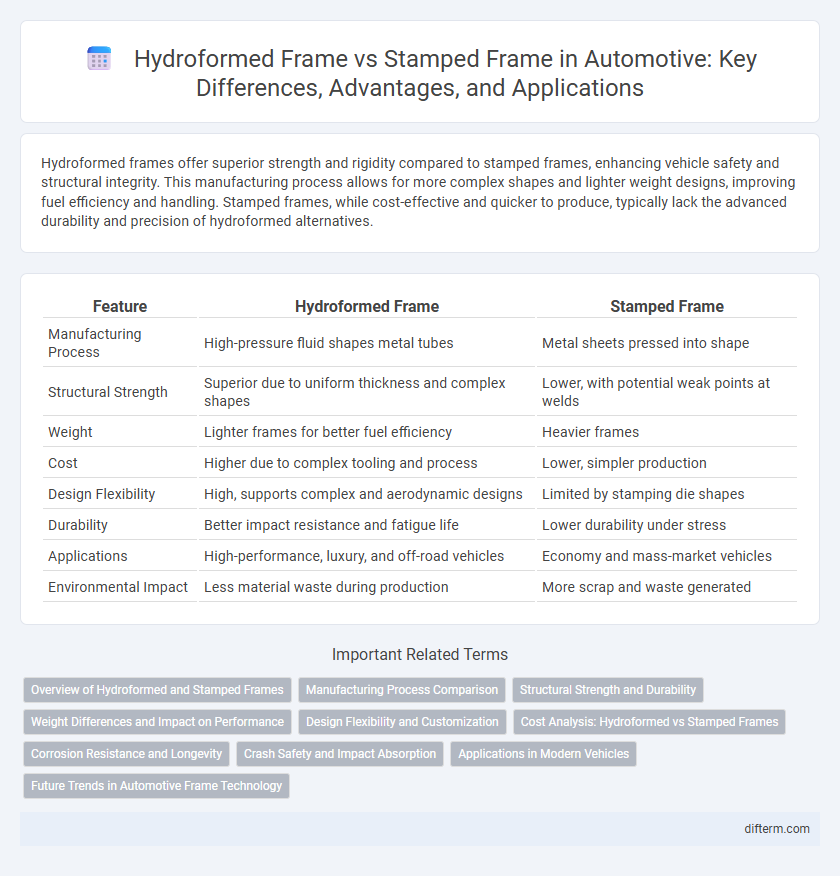

Hydroformed frames offer superior strength and rigidity compared to stamped frames, enhancing vehicle safety and structural integrity. This manufacturing process allows for more complex shapes and lighter weight designs, improving fuel efficiency and handling. Stamped frames, while cost-effective and quicker to produce, typically lack the advanced durability and precision of hydroformed alternatives.

Table of Comparison

| Feature | Hydroformed Frame | Stamped Frame |

|---|---|---|

| Manufacturing Process | High-pressure fluid shapes metal tubes | Metal sheets pressed into shape |

| Structural Strength | Superior due to uniform thickness and complex shapes | Lower, with potential weak points at welds |

| Weight | Lighter frames for better fuel efficiency | Heavier frames |

| Cost | Higher due to complex tooling and process | Lower, simpler production |

| Design Flexibility | High, supports complex and aerodynamic designs | Limited by stamping die shapes |

| Durability | Better impact resistance and fatigue life | Lower durability under stress |

| Applications | High-performance, luxury, and off-road vehicles | Economy and mass-market vehicles |

| Environmental Impact | Less material waste during production | More scrap and waste generated |

Overview of Hydroformed and Stamped Frames

Hydroformed frames use high-pressure fluid to shape metal tubes into complex, lightweight, and strong structural components, enhancing vehicle rigidity and crash safety. Stamped frames rely on pressing sheet metal into shape, offering cost-effective mass production but typically resulting in heavier and less durable structures. The hydroforming process provides precise geometry and improved performance, making it ideal for modern automotive frame manufacturing.

Manufacturing Process Comparison

Hydroformed frames utilize high-pressure fluid to shape tubular steel or aluminum into precise, complex geometries, allowing for greater design flexibility and reduced welding requirements compared to stamped frames. Stamped frames are created by pressing flat metal sheets into shape using dies, which is faster but often results in weaker structural integrity and limited design complexity. The hydroforming process enhances strength-to-weight ratio and durability, making it ideal for advanced automotive chassis manufacturing, while stamping remains cost-effective for high-volume, simpler frame components.

Structural Strength and Durability

Hydroformed frames exhibit superior structural strength and enhanced durability due to their seamless, uniform design that reduces stress concentration points compared to stamped frames. The hydroforming process allows for complex shapes with consistent thickness, improving load distribution and resistance to deformation under high impact or prolonged use. Stamped frames, produced by pressing flat sheets into shape, often contain welded joints that can become points of weakness, resulting in lower overall durability and structural integrity.

Weight Differences and Impact on Performance

Hydroformed frames weigh significantly less than stamped frames due to their seamless, hollow construction, which reduces material usage while maintaining strength. This weight reduction improves fuel efficiency, acceleration, and handling by lowering the vehicle's overall mass and center of gravity. The enhanced rigidity and precise shaping of hydroformed frames contribute to better crash safety and vehicle dynamics compared to heavier, less uniform stamped frames.

Design Flexibility and Customization

Hydroformed frames offer superior design flexibility and customization compared to stamped frames due to their ability to create complex, seamless shapes with high precision. This advanced manufacturing technique allows for optimized strength-to-weight ratios and tailored geometry, enhancing vehicle performance and safety. Stamped frames, while cost-effective for mass production, are limited by the constraints of stamping dies and often result in less intricate designs.

Cost Analysis: Hydroformed vs Stamped Frames

Hydroformed frames typically incur higher initial tooling and production costs due to specialized equipment and processes, while stamped frames benefit from lower setup expenses and faster cycle times. Despite the higher upfront investment, hydroformed frames offer enhanced structural integrity and weight reduction, potentially lowering long-term costs through improved fuel efficiency and durability. Cost analysis must weigh these factors against production volume and performance requirements to determine the optimal manufacturing method in automotive frame design.

Corrosion Resistance and Longevity

Hydroformed frames offer superior corrosion resistance compared to stamped frames due to their seamless design, which minimizes welds and potential points of rust infiltration. The uniform metal thickness and enhanced structural integrity in hydroformed frames contribute to increased longevity, making them more durable under harsh environmental conditions. Stamped frames, often comprising multiple welded pieces, are more susceptible to corrosion at joints, reducing their overall lifespan.

Crash Safety and Impact Absorption

Hydroformed frames exhibit superior crash safety and impact absorption due to their uniform tubular structure that distributes collision forces more evenly across the vehicle chassis. Compared to stamped frames, hydroformed components offer enhanced rigidity and energy dissipation, reducing deformation and improving passenger protection during impacts. This advanced manufacturing technique results in lighter, stronger frames that better manage crash energy, contributing to higher safety ratings in automotive crash tests.

Applications in Modern Vehicles

Hydroformed frames are widely used in modern automotive applications for lightweight trucks, SUVs, and electric vehicles due to their superior strength-to-weight ratio and enhanced crash resistance. Stamped frames remain common in mass-produced passenger cars because of their cost-effectiveness and faster manufacturing cycle. Advancements in hydroforming technology have expanded its adoption in high-performance and luxury vehicles, improving structural rigidity and fuel efficiency.

Future Trends in Automotive Frame Technology

Future trends in automotive frame technology emphasize lightweight hydroformed frames that offer enhanced strength, stiffness, and design flexibility compared to traditional stamped frames. Advancements in high-strength steel and aluminum alloys combined with hydroforming techniques enable improved crashworthiness and fuel efficiency. Integration of smart sensors within hydroformed frames is expected to revolutionize structural health monitoring and predictive maintenance in next-generation vehicles.

hydroformed frame vs stamped frame Infographic

difterm.com

difterm.com