The camshaft and crankshaft are essential components in an automotive engine, each serving distinct roles; the crankshaft converts linear piston motion into rotational motion, powering the vehicle, while the camshaft controls the opening and closing of engine valves for optimal air-fuel mixture and exhaust flow. Precise synchronization between the camshaft and crankshaft ensures efficient engine performance and prevents mechanical failures. Understanding their differences is crucial for diagnosing engine issues and enhancing overall vehicle maintenance.

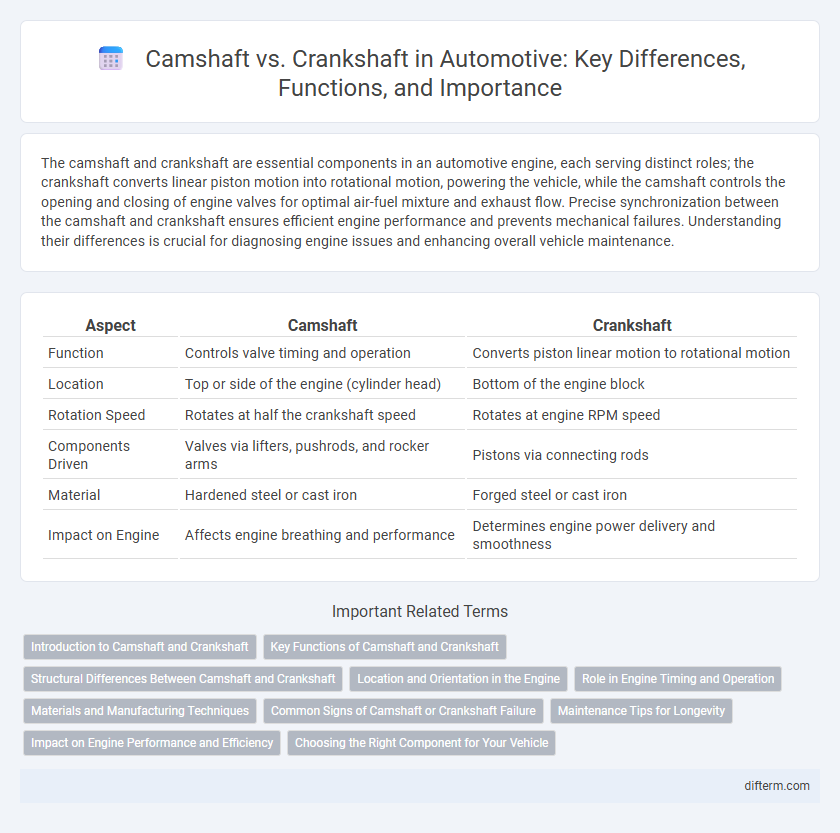

Table of Comparison

| Aspect | Camshaft | Crankshaft |

|---|---|---|

| Function | Controls valve timing and operation | Converts piston linear motion to rotational motion |

| Location | Top or side of the engine (cylinder head) | Bottom of the engine block |

| Rotation Speed | Rotates at half the crankshaft speed | Rotates at engine RPM speed |

| Components Driven | Valves via lifters, pushrods, and rocker arms | Pistons via connecting rods |

| Material | Hardened steel or cast iron | Forged steel or cast iron |

| Impact on Engine | Affects engine breathing and performance | Determines engine power delivery and smoothness |

Introduction to Camshaft and Crankshaft

The camshaft controls the opening and closing of engine valves, directly influencing air-fuel mixture intake and exhaust gas expulsion. The crankshaft converts the linear motion of pistons into rotational motion to power the vehicle's drivetrain. Together, the camshaft and crankshaft coordinate engine timing and efficiency for optimal performance.

Key Functions of Camshaft and Crankshaft

The camshaft controls the timing and operation of the engine's intake and exhaust valves, ensuring optimal air-fuel mixture and exhaust gas expulsion for efficient combustion. The crankshaft converts the linear motion of pistons into rotational motion, providing the engine's primary power output to the drivetrain. Together, these components synchronize engine cycles to maximize performance and fuel efficiency.

Structural Differences Between Camshaft and Crankshaft

The camshaft features lobes or cams that control the opening and closing of engine valves, typically made from cast iron or steel and positioned in the cylinder head or block. The crankshaft, constructed from forged steel or cast iron, consists of offset crankpins and counterweights designed to convert the linear motion of pistons into rotational motion to drive the vehicle. Structurally, the camshaft is slimmer with precise cam profiles, whereas the crankshaft is bulkier, engineered to withstand high torsional forces during engine operation.

Location and Orientation in the Engine

The camshaft is typically located in the cylinder head or above the valves, running parallel to the engine's length to control valve timing and lift. The crankshaft is positioned at the bottom of the engine block, oriented longitudinally to convert piston movement into rotational motion. Precise alignment between the camshaft and crankshaft is crucial for optimal engine performance and timing synchronization.

Role in Engine Timing and Operation

The camshaft controls the timing and operation of the engine's intake and exhaust valves, ensuring precise valve opening and closing for optimal air-fuel mixture and exhaust gas expulsion. The crankshaft converts the linear motion of pistons into rotational motion, driving the vehicle's wheels and maintaining engine balance. Accurate synchronization between the camshaft and crankshaft is essential for proper engine timing, efficient combustion, and overall engine performance.

Materials and Manufacturing Techniques

Camshafts are commonly crafted from cast iron or billet steel, prioritizing wear resistance and precision machining to maintain valve timing accuracy. Crankshafts typically utilize forged steel or cast iron with nodular graphite to withstand high torsional stresses and optimize fatigue strength. Advanced manufacturing techniques such as induction hardening and nitriding are applied to both components to enhance surface durability and extend engine lifespan.

Common Signs of Camshaft or Crankshaft Failure

Common signs of camshaft or crankshaft failure include engine misfires, rough idling, and unusual knocking noises from the engine bay. Reduced engine power, excessive oil consumption, and metal shavings in the oil often indicate wear or damage to these critical engine components. Early detection of issues such as sensor malfunctions or timing irregularities is essential to prevent costly engine repairs and maintain optimal vehicle performance.

Maintenance Tips for Longevity

Regular inspection and timely lubrication of the camshaft and crankshaft are essential to prevent wear and ensure smooth engine performance. Using high-quality engine oil and adhering to manufacturer-recommended oil change intervals minimizes friction and heat buildup on these critical components. Monitoring for unusual noises or vibrations can help detect early signs of camshaft or crankshaft issues, allowing for proactive maintenance and extending their operational lifespan.

Impact on Engine Performance and Efficiency

The camshaft controls the timing and duration of the intake and exhaust valve openings, directly influencing engine breathing and combustion efficiency. The crankshaft converts the pistons' linear motion into rotational force, determining power delivery and torque characteristics. Optimizing the synchronization between camshaft and crankshaft improves engine performance, fuel efficiency, and emissions control.

Choosing the Right Component for Your Vehicle

Selecting the right component between a camshaft and a crankshaft depends on your vehicle's engine type and performance requirements. The camshaft controls valve timing and air-fuel mixture intake, crucial for efficient combustion and power delivery, while the crankshaft converts piston movement into rotational motion to drive the wheels. Understanding your engine's design and desired performance characteristics ensures optimal compatibility and longevity of these essential components.

camshaft vs crankshaft Infographic

difterm.com

difterm.com