A sequential gearbox offers faster and more precise gear shifts compared to an H-pattern gearbox, enhancing performance and driving experience in automotive applications. Unlike the H-pattern, which requires the driver to manually select each gear position, the sequential system simplifies shifting by moving directly through gears in order. This not only reduces shift time but also minimizes the risk of mis-shifting, making it ideal for high-performance and racing vehicles.

Table of Comparison

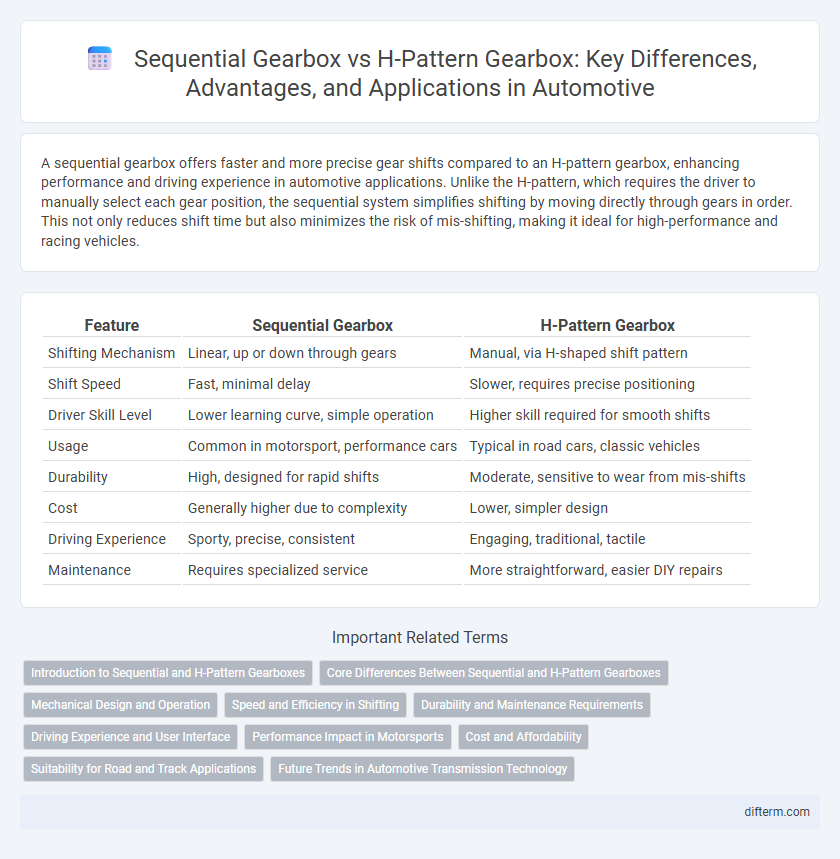

| Feature | Sequential Gearbox | H-Pattern Gearbox |

|---|---|---|

| Shifting Mechanism | Linear, up or down through gears | Manual, via H-shaped shift pattern |

| Shift Speed | Fast, minimal delay | Slower, requires precise positioning |

| Driver Skill Level | Lower learning curve, simple operation | Higher skill required for smooth shifts |

| Usage | Common in motorsport, performance cars | Typical in road cars, classic vehicles |

| Durability | High, designed for rapid shifts | Moderate, sensitive to wear from mis-shifts |

| Cost | Generally higher due to complexity | Lower, simpler design |

| Driving Experience | Sporty, precise, consistent | Engaging, traditional, tactile |

| Maintenance | Requires specialized service | More straightforward, easier DIY repairs |

Introduction to Sequential and H-Pattern Gearboxes

Sequential gearboxes feature a mechanism that allows shifting through gears in a fixed sequence, providing faster and more precise gear changes ideal for high-performance automotive applications. In contrast, H-pattern gearboxes employ a traditional manual layout where the driver selects gears via an H-shaped gate, offering greater control and familiarity favored in everyday driving and classic vehicles. Understanding the mechanical differences and intended usage scenarios is essential for selecting the appropriate gearbox type based on performance needs and driving style.

Core Differences Between Sequential and H-Pattern Gearboxes

Sequential gearboxes enable faster gear changes by allowing drivers to shift up or down in a fixed order, using a simple push or pull mechanism, which enhances performance and reduces shift time. H-pattern gearboxes require manual selection of gears across an H-shaped gate, offering greater control and driver engagement but slower shift speeds. Core differences lie in their shifting mechanisms, speed of gear changes, and the level of driver involvement, with sequential boxes favored in racing for efficiency and H-pattern used in traditional driving for precision.

Mechanical Design and Operation

Sequential gearboxes utilize a ratchet mechanism for gear shifts, enabling rapid, linear movement through gears without the need to navigate an H-pattern. Their design features a selector drum that rotates to engage gear forks, providing precise and consistent gear changes ideal for high-performance automotive applications. In contrast, H-pattern gearboxes rely on an H-shaped shift gate and individual gear selectors, requiring the driver to manually position the gear lever into each gear slot, resulting in slower and less consistent shifts.

Speed and Efficiency in Shifting

Sequential gearboxes enable faster and more efficient shifting by allowing drivers to change gears in a linear sequence without the need to navigate an H-pattern, reducing shift times and minimizing missed shifts. This direct and simplified shifting mechanism enhances overall driving performance, especially in high-speed or racing scenarios. H-pattern gearboxes, while offering more control over gear selection, generally result in slower shift speeds and increased driver effort, impacting efficiency during rapid gear changes.

Durability and Maintenance Requirements

Sequential gearboxes offer enhanced durability due to fewer moving parts and a simplified shifting mechanism, reducing wear and tear compared to traditional H-pattern gearboxes. Maintenance requirements for sequential gearboxes are generally lower, with less frequent clutch adjustments and reduced risk of gear misalignment. H-pattern gearboxes, while robust, demand more regular maintenance to ensure precise gear engagement and longevity under intensive use.

Driving Experience and User Interface

Sequential gearboxes offer a smoother and faster shifting experience compared to H-pattern gearboxes, enhancing performance and driving precision. The linear shift pattern in sequential gearboxes reduces the likelihood of misshifts, providing more confidence and control during aggressive driving. H-pattern gearboxes deliver a more traditional and engaging driving interface, appealing to enthusiasts who value tactile feedback and deliberate gear changes.

Performance Impact in Motorsports

Sequential gearboxes enable faster and more precise gear changes than H-pattern gearboxes, significantly improving lap times and vehicle control in motorsports. Their design reduces shift effort and minimizes the risk of missed gears, allowing drivers to maintain optimal power delivery during high-speed maneuvers. Many racing series, including MotoGP and Formula 1, exclusively use sequential gearboxes due to their superior performance benefits.

Cost and Affordability

Sequential gearboxes typically cost more than H-pattern gearboxes due to their complex design and advanced materials, making them less affordable for everyday consumers. H-pattern gearboxes are simpler, cheaper to manufacture, and widely available, which contributes to their cost-effectiveness in mass-market vehicles. The affordability difference makes H-pattern gearboxes more common in budget and mid-range cars, while sequential gearboxes are often reserved for high-performance and racing applications.

Suitability for Road and Track Applications

Sequential gearboxes offer rapid, precise gear changes ideal for track applications where speed and efficiency are critical. H-pattern gearboxes provide greater control and engagement, making them well-suited for road use and enthusiasts favoring traditional driving experiences. The choice depends on prioritizing performance in competitive environments or versatility and feedback on everyday driving.

Future Trends in Automotive Transmission Technology

Future automotive transmission technology heavily emphasizes the integration of advanced sequential gearboxes, which offer smoother, faster, and more precise gear shifts compared to traditional H-pattern gearboxes. Innovations in electronic control units (ECUs) and smart sensor systems enhance the performance and adaptability of sequential gearboxes, making them ideal for both high-performance and electric vehicles. The shift towards electrification and autonomous driving further supports the dominance of sequential transmissions due to their compatibility with automated gear changes and improved efficiency.

sequential gearbox vs H-pattern gearbox Infographic

difterm.com

difterm.com