Flat-plane crank engines deliver a more aggressive exhaust note and higher revving capabilities, favored in high-performance sports cars for their responsiveness and reduced rotational inertia. Cross-plane crank engines provide smoother power delivery with less vibration, commonly used in muscle cars and trucks for enhanced torque and drivability. Choosing between the two depends on prioritizing either sharp throttle response and sound character or balanced smoothness and low-end torque for automotive pets.

Table of Comparison

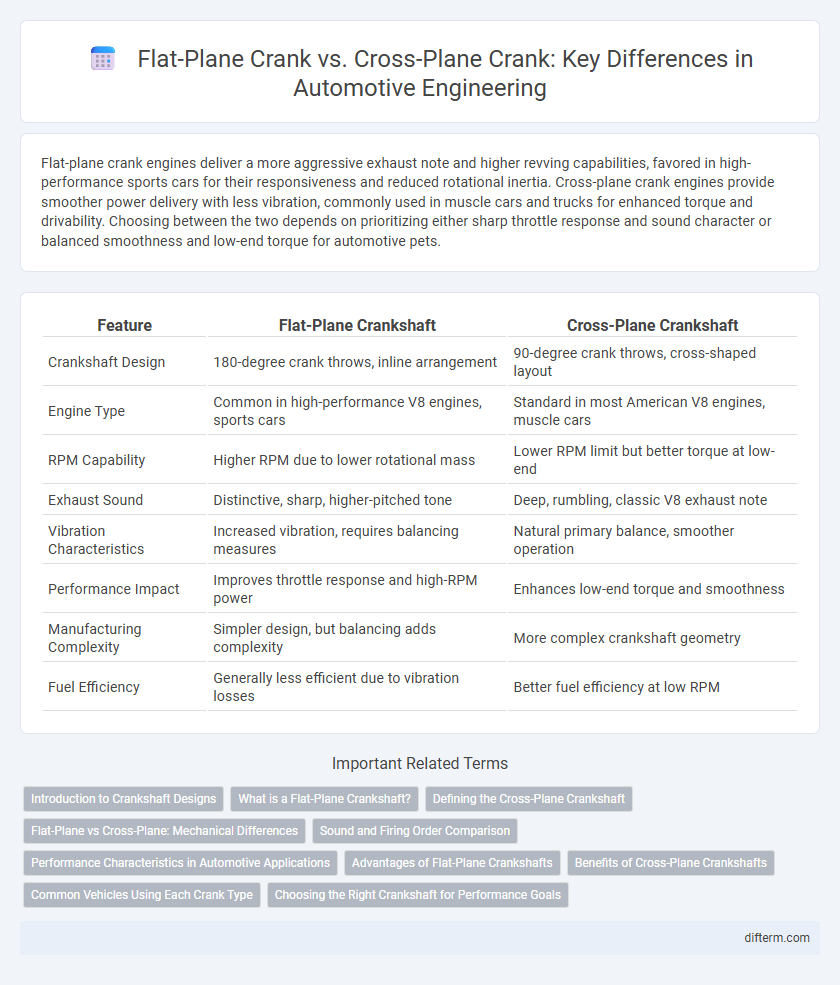

| Feature | Flat-Plane Crankshaft | Cross-Plane Crankshaft |

|---|---|---|

| Crankshaft Design | 180-degree crank throws, inline arrangement | 90-degree crank throws, cross-shaped layout |

| Engine Type | Common in high-performance V8 engines, sports cars | Standard in most American V8 engines, muscle cars |

| RPM Capability | Higher RPM due to lower rotational mass | Lower RPM limit but better torque at low-end |

| Exhaust Sound | Distinctive, sharp, higher-pitched tone | Deep, rumbling, classic V8 exhaust note |

| Vibration Characteristics | Increased vibration, requires balancing measures | Natural primary balance, smoother operation |

| Performance Impact | Improves throttle response and high-RPM power | Enhances low-end torque and smoothness |

| Manufacturing Complexity | Simpler design, but balancing adds complexity | More complex crankshaft geometry |

| Fuel Efficiency | Generally less efficient due to vibration losses | Better fuel efficiency at low RPM |

Introduction to Crankshaft Designs

Flat-plane crankshafts feature a 180-degree crankpin arrangement, promoting high-revving engine performance and reduced rotational inertia, commonly found in performance V8 engines like those in Ferrari models. Cross-plane crankshafts use a 90-degree crankpin configuration, delivering smoother operation and better torque at low RPMs, making them prevalent in American V8 muscle cars such as the Chevrolet Corvette. Understanding these fundamental crankshaft designs helps engineers balance power output, vibration characteristics, and engine sound in automotive applications.

What is a Flat-Plane Crankshaft?

A flat-plane crankshaft features a 180-degree crankpin separation, commonly used in high-performance V8 engines to reduce rotational inertia and enable faster engine revving. This design improves exhaust scavenging and enhances engine responsiveness, contributing to higher power output and a distinctive exhaust note. Compared to the traditional cross-plane crankshaft, the flat-plane offers better balance in inline-four and V8 configurations but may produce more vibration.

Defining the Cross-Plane Crankshaft

The cross-plane crankshaft features four crankpins positioned at 90-degree intervals, balancing primary and secondary engine vibrations for smoother performance. Commonly found in V8 engines, this design delivers a distinctive exhaust note and improved low-end torque. Its configuration enhances engine durability and reduces stress on components during high RPM operation.

Flat-Plane vs Cross-Plane: Mechanical Differences

Flat-plane crankshafts feature a 180-degree crankpin arrangement that reduces rotational mass and increases engine responsiveness, commonly found in high-performance sports cars. Cross-plane crankshafts utilize a 90-degree crankpin configuration, providing better primary balance and smoother operation, typical in American V8 engines. The mechanical differences between flat-plane and cross-plane designs significantly impact engine vibration, sound characteristics, and power delivery.

Sound and Firing Order Comparison

Flat-plane crankshafts produce a higher-pitched, more aggressive exhaust note due to their evenly spaced firing intervals, often found in high-performance sports cars like the Ferrari 458. Cross-plane crankshafts generate a deeper, rumbling sound with uneven firing orders typical of American V8 engines such as the Ford Mustang GT. The flat-plane's firing order results in less vibration and allows for quicker engine response, while the cross-plane design provides smoother power delivery and a characteristic burble.

Performance Characteristics in Automotive Applications

Flat-plane crankshafts deliver higher engine RPM capabilities and quicker throttle response due to their lower rotating mass and reduced inertia, making them ideal for high-performance sports cars. Cross-plane crankshafts produce smoother power delivery and better low-end torque by balancing secondary vibrations, which enhances drivability in muscle cars and trucks. The choice between flat-plane and cross-plane cranks significantly influences engine sound, vibration, and overall performance characteristics in automotive applications.

Advantages of Flat-Plane Crankshafts

Flat-plane crankshafts offer superior engine responsiveness and higher RPM capabilities due to reduced rotational inertia and evenly spaced firing intervals. Their lightweight design enhances overall performance by improving throttle response and enabling efficient exhaust scavenging. This makes flat-plane cranks ideal for high-performance sports cars and racing applications where precision and speed are critical.

Benefits of Cross-Plane Crankshafts

Cross-plane crankshafts provide smoother engine operation by reducing vibrations through their 90-degree crankpin arrangement, enhancing overall ride comfort. They improve torque delivery at low to mid-range RPMs, making vehicles more responsive in everyday driving conditions. Additionally, cross-plane designs optimize exhaust scavenging, contributing to better engine efficiency and reduced emissions.

Common Vehicles Using Each Crank Type

High-performance sports cars and exotic supercars, such as the Ferrari 458 Italia and Ford Mustang Shelby GT350, commonly use flat-plane crankshafts due to their ability to deliver higher RPMs and a more aggressive exhaust note. In contrast, mainstream V8 engines found in vehicles like the Chevrolet Camaro and Dodge Charger predominantly utilize cross-plane crankshafts, favored for their smoother operation and better low-end torque. These distinctions influence engine character and performance, shaping the driving experience in various automotive segments.

Choosing the Right Crankshaft for Performance Goals

Flat-plane crankshafts offer higher RPM capabilities and improved throttle response, ideal for maximizing horsepower in sports cars and racing applications. Cross-plane crankshafts provide smoother operation with better low-end torque and reduced vibration, suitable for muscle cars and everyday drivability. Choosing the right crankshaft depends on balancing high-revving performance against engine smoothness and torque characteristics to meet specific automotive performance goals.

flat-plane crank vs cross-plane crank Infographic

difterm.com

difterm.com