Pushrod suspension systems offer superior adjustability and accessibility by positioning the shock absorbers horizontally, improving vehicle center of gravity and handling responsiveness. Pullrod suspension setups lower the center of gravity further by mounting the rods downward, enhancing aerodynamic performance and reducing unsprung weight in high-performance racing cars. Both systems optimize suspension geometry, but the choice depends on balancing ease of setup and aerodynamic priorities in automotive applications.

Table of Comparison

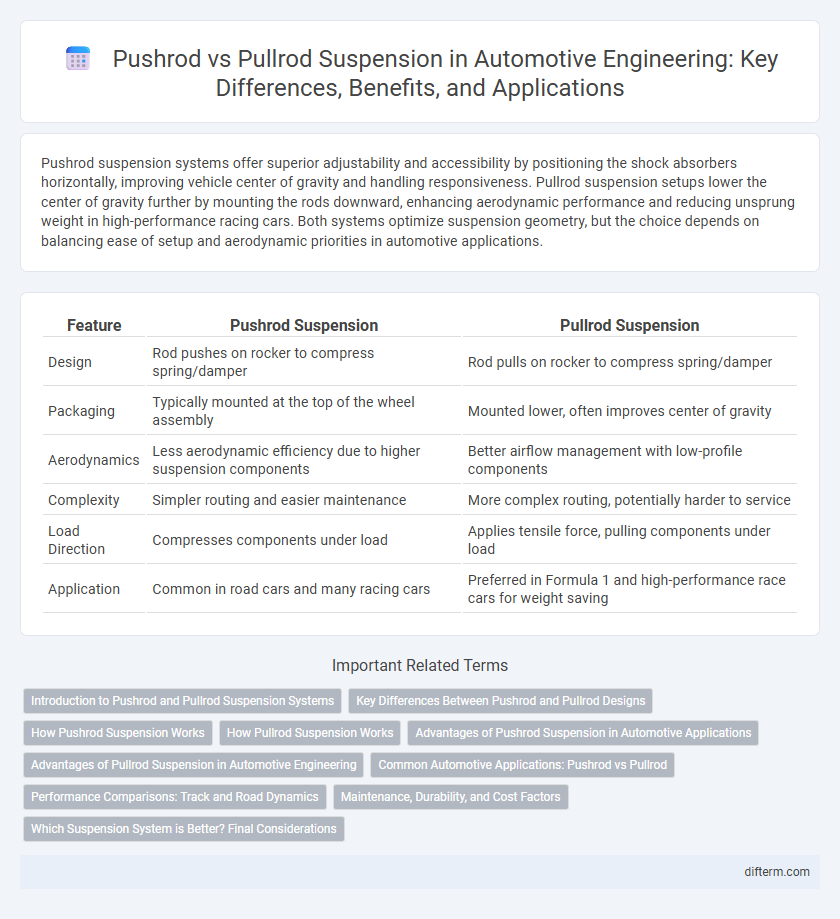

| Feature | Pushrod Suspension | Pullrod Suspension |

|---|---|---|

| Design | Rod pushes on rocker to compress spring/damper | Rod pulls on rocker to compress spring/damper |

| Packaging | Typically mounted at the top of the wheel assembly | Mounted lower, often improves center of gravity |

| Aerodynamics | Less aerodynamic efficiency due to higher suspension components | Better airflow management with low-profile components |

| Complexity | Simpler routing and easier maintenance | More complex routing, potentially harder to service |

| Load Direction | Compresses components under load | Applies tensile force, pulling components under load |

| Application | Common in road cars and many racing cars | Preferred in Formula 1 and high-performance race cars for weight saving |

Introduction to Pushrod and Pullrod Suspension Systems

Pushrod and pullrod suspension systems are advanced automotive setups primarily used in high-performance and racing vehicles to optimize handling and aerodynamics. Pushrod suspension features rods that transfer forces from the wheel to the chassis by pushing on the rocker arms, while pullrod suspension uses rods that pull on the rocker arms, allowing for a lower center of gravity and improved airflow under the car. Both systems enhance vehicle stability and responsiveness by enabling precise control over suspension geometry and weight distribution.

Key Differences Between Pushrod and Pullrod Designs

Pushrod suspension systems transfer forces through rods pushing upward from the wheel hub to the chassis, providing easier access for shock absorber placement and improved maintenance. Pullrod suspension designs pull the wheel hub upward via rods angled downward toward the chassis, allowing for lower center of gravity and better aerodynamic efficiency. Key differences include the direction of force transmission, packaging constraints, and their impact on vehicle handling dynamics.

How Pushrod Suspension Works

Pushrod suspension operates by transferring forces from the wheel to the chassis through a pushrod connected to a rocker arm, which compresses the spring and damper unit mounted inboard. This design allows for better aerodynamics and weight distribution by positioning suspension components inside the vehicle body, reducing unsprung mass. The pushrod's direct linear motion improves suspension response and handling precision in high-performance automotive applications.

How Pullrod Suspension Works

Pullrod suspension operates by connecting the wheel assembly to the chassis through a rod that pulls on the rocker arm, transferring vertical wheel movement into compressive force on the shock absorber and spring. This design lowers the center of gravity and improves aerodynamics by allowing suspension components to be positioned lower and more compactly within the vehicle. Commonly used in high-performance and Formula 1 cars, pullrod suspension enhances handling precision and responsiveness on varying road surfaces.

Advantages of Pushrod Suspension in Automotive Applications

Pushrod suspension systems in automotive applications offer superior packaging flexibility, allowing engineers to position heavy components like springs and dampers lower in the chassis, which lowers the vehicle's center of gravity and enhances handling stability. This design facilitates easier adjustments and maintenance compared to pullrod setups, improving suspension tuning efficiency and reducing downtime. Furthermore, pushrod suspensions provide improved aerodynamic performance by enabling cleaner airflow underneath the vehicle due to their more compact and elevated linkage arrangement.

Advantages of Pullrod Suspension in Automotive Engineering

Pullrod suspension systems offer significant advantages in automotive engineering by enabling a lower center of gravity, which enhances vehicle stability and handling precision. Their compact design improves aerodynamic efficiency by allowing smoother airflow over the chassis compared to bulkier pushrod setups. Lightweight construction and better packaging flexibility in tight spaces make pullrod suspensions ideal for high-performance and racing vehicles aiming to maximize cornering performance and responsiveness.

Common Automotive Applications: Pushrod vs Pullrod

Pushrod suspension systems are commonly used in high-performance vehicles and race cars due to their ability to lower the center of gravity and improve aerodynamics by positioning the springs and dampers inside the chassis. Pullrod suspension is favored in Formula 1 and some sports cars for its compact design that allows for better airflow and reduced unsprung weight, enhancing handling and responsiveness. Both systems are employed in automotive applications where precise suspension tuning and weight distribution are critical for optimal vehicle dynamics and performance.

Performance Comparisons: Track and Road Dynamics

Pushrod suspension systems provide superior aerodynamic efficiency and lower unsprung weight, enhancing high-speed stability and cornering precision on the track. Pullrod suspension setups offer a lower center of gravity and improved weight distribution, resulting in better handling and responsiveness on uneven road surfaces. Performance comparisons highlight pushrod's advantage in maximizing downforce in racing conditions, while pullrod systems excel in maintaining tire contact and ride comfort during dynamic road driving.

Maintenance, Durability, and Cost Factors

Pushrod suspension systems typically offer easier maintenance due to better accessibility of components compared to pullrod setups, which are often more compact but harder to service. Durability in pushrod suspensions benefits from straightforward designs with fewer stress points, while pullrod suspensions may experience increased wear in high-stress racing environments due to tighter packaging. Cost factors lean in favor of pushrod suspensions as they require less precision manufacturing and simpler replacement parts, whereas pullrod systems often incur higher expenses from specialized components and complex installation procedures.

Which Suspension System is Better? Final Considerations

Pushrod suspension offers superior ride quality and easier maintenance due to its upright shock positioning, while pullrod suspension provides improved aerodynamics and a lower center of gravity by mounting shocks lower and more horizontally. The choice between pushrod and pullrod systems depends on vehicle design goals, with pushrod favored for comfort and serviceability, and pullrod preferred in high-performance applications where aerodynamic efficiency is critical. Final considerations should include factors like track type, weight distribution, and handling characteristics to determine the optimal suspension setup.

pushrod suspension vs pullrod suspension Infographic

difterm.com

difterm.com