Stockout in retail pet stores leads to missed sales opportunities and dissatisfied customers when popular pet products run out of availability. Overstock results in excess inventory that ties up capital and increases risks of product expiration or obsolescence, especially with perishable pet supplies. Balancing inventory levels through accurate demand forecasting and efficient supply chain management is critical to optimizing sales and customer satisfaction.

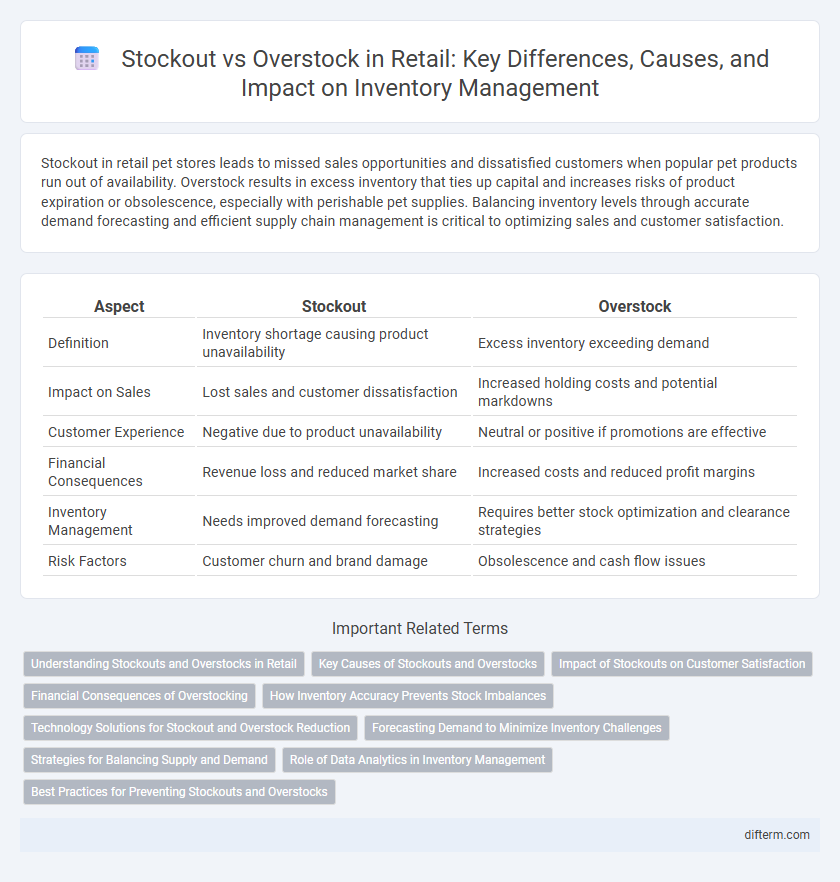

Table of Comparison

| Aspect | Stockout | Overstock |

|---|---|---|

| Definition | Inventory shortage causing product unavailability | Excess inventory exceeding demand |

| Impact on Sales | Lost sales and customer dissatisfaction | Increased holding costs and potential markdowns |

| Customer Experience | Negative due to product unavailability | Neutral or positive if promotions are effective |

| Financial Consequences | Revenue loss and reduced market share | Increased costs and reduced profit margins |

| Inventory Management | Needs improved demand forecasting | Requires better stock optimization and clearance strategies |

| Risk Factors | Customer churn and brand damage | Obsolescence and cash flow issues |

Understanding Stockouts and Overstocks in Retail

Stockouts occur when inventory levels fall below demand, causing missed sales and dissatisfied customers, while overstocks tie up capital and increase holding costs due to excess inventory. Efficient demand forecasting and inventory management systems help retailers balance stock levels, reducing the risks associated with stockouts and overstocks. Data-driven approaches using real-time sales analytics optimize reorder points and safety stock, enhancing overall supply chain performance.

Key Causes of Stockouts and Overstocks

Ineffective demand forecasting and supply chain disruptions are primary causes of stockouts, leading to lost sales and diminished customer trust. Overstock frequently results from inaccurate inventory management, supplier delays, or sudden drops in consumer demand, causing increased holding costs and potential product obsolescence. Retailers must address these issues by leveraging advanced analytics and real-time inventory tracking to balance stock levels efficiently.

Impact of Stockouts on Customer Satisfaction

Stockouts severely impact customer satisfaction by causing frustration and eroding trust in a retailer's reliability. Frequent stockouts lead to lost sales opportunities as customers turn to competitors to fulfill their needs. Ensuring optimal inventory levels minimizes stockouts, enhances shopping experiences, and promotes customer loyalty.

Financial Consequences of Overstocking

Overstocking in retail leads to increased holding costs, including warehousing, insurance, and depreciation, which directly diminish profit margins. Excess inventory ties up capital that could be invested in more profitable assets, reducing overall liquidity and financial flexibility. Prolonged overstock can result in markdowns and write-offs, further eroding revenue and impacting the retailer's financial stability.

How Inventory Accuracy Prevents Stock Imbalances

Inventory accuracy plays a critical role in preventing stock imbalances by ensuring real-time data reflects actual product quantities, reducing the risk of stockouts and overstocks. Accurate inventory management systems use barcoding, RFID, and automated counting to maintain precise stock levels, enabling retailers to forecast demand more effectively. By minimizing discrepancies between recorded and physical inventory, businesses optimize inventory turnover, enhance customer satisfaction, and reduce carrying costs.

Technology Solutions for Stockout and Overstock Reduction

Advanced inventory management systems leverage artificial intelligence and real-time data analytics to predict demand patterns accurately, reducing stockouts and overstock situations in retail operations. Automated replenishment tools integrate with point-of-sale data to optimize stock levels, minimizing lost sales from stockouts while curbing excess inventory carrying costs. IoT sensors and RFID technology enhance supply chain visibility, enabling retailers to respond swiftly to inventory fluctuations and maintain balanced stock levels.

Forecasting Demand to Minimize Inventory Challenges

Accurate forecasting demand is crucial for balancing stockout and overstock situations, reducing lost sales and excess inventory costs. Leveraging advanced analytics and historical sales data enables retailers to predict consumer demand more precisely, optimizing inventory levels. Implementing demand forecasting tools helps maintain product availability while minimizing holding costs and markdown risks.

Strategies for Balancing Supply and Demand

Effective stockout and overstock strategies hinge on accurate demand forecasting and real-time inventory tracking to balance supply and demand. Implementing just-in-time replenishment and safety stock optimization reduces excessive inventory costs while preventing lost sales due to stockouts. Leveraging data analytics and automated replenishment systems enhances decision-making and responsiveness in retail inventory management.

Role of Data Analytics in Inventory Management

Data analytics plays a critical role in minimizing stockouts and overstock by providing real-time insights into inventory levels, demand patterns, and customer behavior. Advanced algorithms forecast demand more accurately, enabling retailers to optimize reorder points and quantities, thus reducing lost sales and holding costs. Leveraging data-driven inventory management enhances supply chain efficiency and improves customer satisfaction by maintaining optimal stock levels.

Best Practices for Preventing Stockouts and Overstocks

Effective inventory management relies on accurate demand forecasting and real-time data analytics to prevent stockouts and overstocks in retail. Implementing automated replenishment systems and maintaining safety stock levels tailored to sales velocity reduces the risk of inventory imbalances. Regularly reviewing supplier performance and adopting just-in-time inventory strategies further optimize stock levels and improve customer satisfaction.

Stockout vs Overstock Infographic

difterm.com

difterm.com