Drop shipping in retail pet allows stores to sell products directly from suppliers without holding inventory, reducing overhead costs and expanding product variety. Cross docking streamlines distribution by transferring products from incoming to outgoing shipments quickly, minimizing storage time and improving delivery speed. Choosing between drop shipping and cross docking depends on balancing inventory control, delivery efficiency, and customer service priorities.

Table of Comparison

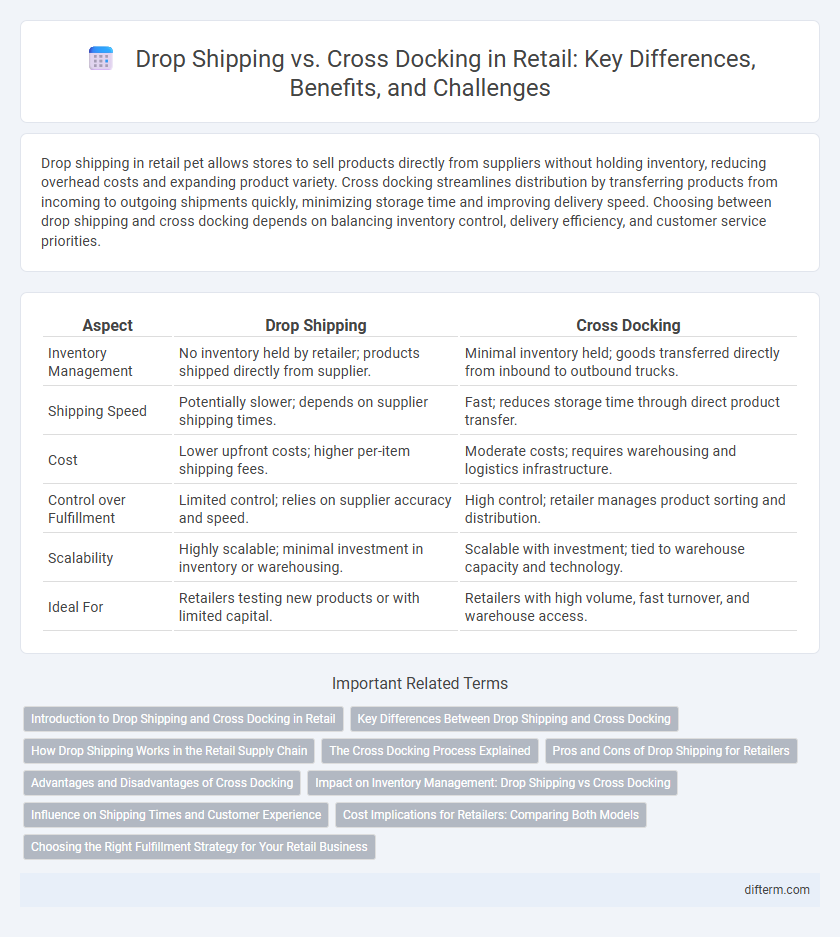

| Aspect | Drop Shipping | Cross Docking |

|---|---|---|

| Inventory Management | No inventory held by retailer; products shipped directly from supplier. | Minimal inventory held; goods transferred directly from inbound to outbound trucks. |

| Shipping Speed | Potentially slower; depends on supplier shipping times. | Fast; reduces storage time through direct product transfer. |

| Cost | Lower upfront costs; higher per-item shipping fees. | Moderate costs; requires warehousing and logistics infrastructure. |

| Control over Fulfillment | Limited control; relies on supplier accuracy and speed. | High control; retailer manages product sorting and distribution. |

| Scalability | Highly scalable; minimal investment in inventory or warehousing. | Scalable with investment; tied to warehouse capacity and technology. |

| Ideal For | Retailers testing new products or with limited capital. | Retailers with high volume, fast turnover, and warehouse access. |

Introduction to Drop Shipping and Cross Docking in Retail

Drop shipping in retail involves directly shipping products from suppliers to customers without holding inventory, enabling businesses to minimize storage costs and streamline order fulfillment. Cross docking, on the other hand, emphasizes rapid transfer of products from inbound to outbound transportation within a distribution center, reducing warehousing time and improving supply chain efficiency. Both methods enhance inventory management but differ significantly in operational processes and logistics strategies.

Key Differences Between Drop Shipping and Cross Docking

Drop shipping involves selling products without holding inventory, where retailers transfer customer orders directly to suppliers for shipment, while cross docking uses a distribution strategy where goods from suppliers are unloaded and immediately loaded onto outbound trucks with minimal storage. Drop shipping relies heavily on supplier reliability and longer shipping times, whereas cross docking emphasizes speed and efficiency by minimizing warehouse storage and handling. Key differences include inventory management, with drop shipping eliminating stockholding versus cross docking requiring coordinated logistics to facilitate rapid transfer through distribution centers.

How Drop Shipping Works in the Retail Supply Chain

Drop shipping in the retail supply chain enables retailers to sell products without holding inventory by directly forwarding customer orders to suppliers or manufacturers for fulfillment. This model reduces warehousing costs and minimizes inventory risk, allowing faster market entry and expanded product offerings. Retailers act primarily as intermediaries, focusing on marketing and customer service while relying on third-party suppliers for storage, packaging, and shipping logistics.

The Cross Docking Process Explained

Cross docking in retail involves transferring products directly from inbound to outbound trucks with minimal or no storage time, streamlining the supply chain and reducing inventory costs. This process requires precise coordination between suppliers, warehouses, and transport to ensure efficient sorting, consolidation, and dispatching of goods to meet demand swiftly. By eliminating warehousing stages, cross docking enhances delivery speed and lowers handling expenses compared to traditional drop shipping models.

Pros and Cons of Drop Shipping for Retailers

Drop shipping offers retailers the advantage of low upfront inventory costs and reduced need for warehouse space, enabling quick scaling and product variety expansion with minimal risk. However, reliance on third-party suppliers can lead to challenges such as longer shipping times, limited quality control, and potential inventory inaccuracies that may impact customer satisfaction. Efficient retailer coordination and robust supplier management systems are crucial to mitigating these drawbacks and maintaining seamless order fulfillment.

Advantages and Disadvantages of Cross Docking

Cross docking reduces inventory holding costs and speeds up order fulfillment by directly transferring goods from inbound to outbound transportation without storage. It requires precise coordination and reliable supply chain partners to avoid delays and stockouts, making it less flexible for handling product variety or unexpected demand spikes. While cross docking enhances efficiency in distribution centers, the need for real-time information and advanced technology can increase operational complexity and initial setup costs.

Impact on Inventory Management: Drop Shipping vs Cross Docking

Drop shipping minimizes inventory holding by directly shipping products from suppliers to customers, reducing storage costs and risks of overstocking. Cross docking involves rapid transfer of goods from inbound to outbound transportation, streamlining inventory flow and decreasing warehouse dwell time but requires synchronized supply chain coordination. Both methods enhance inventory turnover, yet cross docking demands more precise timing and infrastructure, while drop shipping shifts inventory management responsibilities to suppliers.

Influence on Shipping Times and Customer Experience

Drop shipping eliminates the need for inventory storage by shipping products directly from suppliers to customers, often resulting in longer and less predictable shipping times that can impact customer satisfaction. Cross docking reduces inventory holding and accelerates order fulfillment by quickly transferring goods from inbound to outbound trucks, significantly shortening shipping times and enhancing the overall customer experience. Retailers leveraging cross docking benefit from faster delivery, which drives higher customer retention and positive reviews compared to the variability seen in drop shipping logistics.

Cost Implications for Retailers: Comparing Both Models

Drop shipping minimizes upfront inventory investments and warehousing costs, reducing financial risk for retailers but often involves higher per-unit fulfillment fees. Cross docking lowers storage expenses by rapidly transferring goods from inbound to outbound transportation, enhancing inventory turnover but requires significant infrastructure and coordinated logistics, which can increase operational costs. Retailers must weigh the balance between lower inventory holding costs in drop shipping and the efficiency-driven cost savings of cross docking to optimize their supply chain expenses.

Choosing the Right Fulfillment Strategy for Your Retail Business

Choosing the right fulfillment strategy for your retail business depends on factors such as inventory control, shipping speed, and cost efficiency. Drop shipping minimizes inventory holding by directly shipping products from suppliers to customers, ideal for businesses with limited storage capacity and broad product ranges. Cross docking accelerates order fulfillment by transferring goods directly from inbound to outbound transportation, reducing warehousing time and improving delivery speed for retailers with high volume and frequent shipments.

Drop Shipping vs Cross Docking Infographic

difterm.com

difterm.com