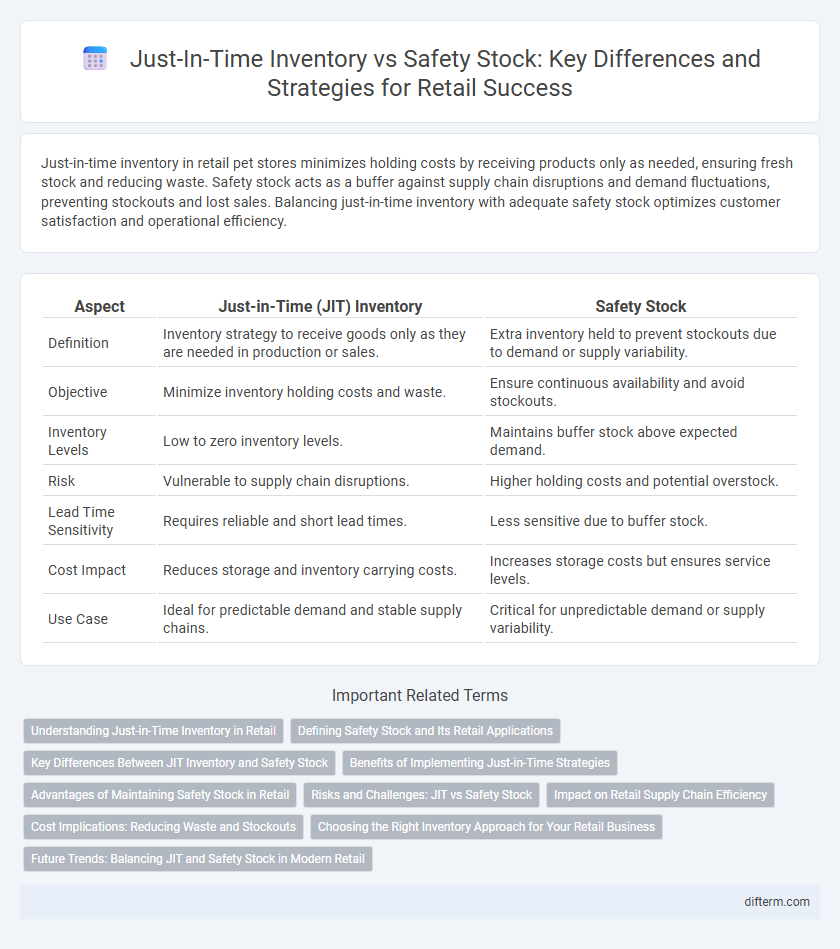

Just-in-time inventory in retail pet stores minimizes holding costs by receiving products only as needed, ensuring fresh stock and reducing waste. Safety stock acts as a buffer against supply chain disruptions and demand fluctuations, preventing stockouts and lost sales. Balancing just-in-time inventory with adequate safety stock optimizes customer satisfaction and operational efficiency.

Table of Comparison

| Aspect | Just-in-Time (JIT) Inventory | Safety Stock |

|---|---|---|

| Definition | Inventory strategy to receive goods only as they are needed in production or sales. | Extra inventory held to prevent stockouts due to demand or supply variability. |

| Objective | Minimize inventory holding costs and waste. | Ensure continuous availability and avoid stockouts. |

| Inventory Levels | Low to zero inventory levels. | Maintains buffer stock above expected demand. |

| Risk | Vulnerable to supply chain disruptions. | Higher holding costs and potential overstock. |

| Lead Time Sensitivity | Requires reliable and short lead times. | Less sensitive due to buffer stock. |

| Cost Impact | Reduces storage and inventory carrying costs. | Increases storage costs but ensures service levels. |

| Use Case | Ideal for predictable demand and stable supply chains. | Critical for unpredictable demand or supply variability. |

Understanding Just-in-Time Inventory in Retail

Just-in-time (JIT) inventory in retail minimizes holding costs by aligning stock levels closely with actual customer demand, reducing excess inventory and waste. This approach relies on precise demand forecasting and efficient supplier coordination to ensure products arrive exactly when needed for sale. In contrast, safety stock serves as a buffer to protect against supply chain disruptions and unexpected demand spikes, often leading to higher carrying costs.

Defining Safety Stock and Its Retail Applications

Safety stock refers to the extra inventory held by retailers to prevent stockouts caused by unpredictable demand or supply chain delays. In retail, maintaining safety stock ensures product availability during fluctuations, reducing lost sales and improving customer satisfaction. Effective safety stock management balances carrying costs with service levels to optimize inventory turnover and profitability.

Key Differences Between JIT Inventory and Safety Stock

Just-in-time (JIT) inventory minimizes stock levels by receiving goods only as they are needed, reducing storage costs and waste, while safety stock involves maintaining extra inventory to buffer against demand fluctuations and supply delays. JIT relies on highly accurate demand forecasting and timely supplier deliveries, whereas safety stock prioritizes risk mitigation and continuity of sales during uncertainties. Retailers using JIT benefit from lean operations but face potential stockouts, whereas those using safety stock ensure availability at the expense of higher holding costs.

Benefits of Implementing Just-in-Time Strategies

Implementing Just-in-Time (JIT) inventory strategies in retail significantly reduces carrying costs by minimizing excess stock and storage requirements. JIT enhances cash flow management and operational efficiency by aligning inventory levels closely with actual consumer demand. This approach decreases waste, lowers the risk of obsolescence, and improves responsiveness to market fluctuations compared to holding large safety stock.

Advantages of Maintaining Safety Stock in Retail

Maintaining safety stock in retail ensures product availability during demand fluctuations, reducing the risk of stockouts and lost sales. It buffers against supply chain delays and unexpected disruptions, enhancing customer satisfaction and loyalty. Safety stock supports consistent inventory levels, enabling retailers to meet peak demand without over-relying on expedited replenishment costs.

Risks and Challenges: JIT vs Safety Stock

Just-in-time (JIT) inventory reduces holding costs but increases risks of stockouts due to supply chain disruptions and demand variability, impacting retail sales and customer satisfaction. Safety stock acts as a buffer against uncertainties in lead times and demand fluctuations, but it ties up capital and increases warehousing expenses. Retailers must balance the lower costs of JIT with the risk mitigation benefits of safety stock to maintain optimal inventory levels and ensure product availability.

Impact on Retail Supply Chain Efficiency

Just-in-time inventory minimizes holding costs and reduces waste by synchronizing stock arrivals with demand, significantly enhancing retail supply chain efficiency through lean operations. Safety stock acts as a buffer against demand variability and supply delays, preventing stockouts but increasing carrying costs and storage requirements. Balancing just-in-time inventory with adequate safety stock levels enables retailers to optimize service levels while maintaining cost-effective supply chain performance.

Cost Implications: Reducing Waste and Stockouts

Just-in-time inventory minimizes carrying costs by aligning stock levels closely with demand, significantly reducing storage expenses and waste from unsold products. Conversely, maintaining safety stock increases holding costs but mitigates the risk of costly stockouts and lost sales in volatile retail environments. Balancing just-in-time strategies with appropriate safety stock levels optimizes cost efficiency by preventing excess inventory while ensuring product availability.

Choosing the Right Inventory Approach for Your Retail Business

Choosing the right inventory approach for your retail business depends on factors like demand variability, lead times, and storage costs. Just-in-time inventory minimizes holding costs by ordering stock precisely when needed, ideal for stable demand and reliable suppliers. Safety stock provides a buffer against supply chain disruptions and demand spikes, essential for businesses facing unpredictable markets or longer replenishment cycles.

Future Trends: Balancing JIT and Safety Stock in Modern Retail

Future retail inventory management increasingly integrates advanced AI analytics to optimize the balance between just-in-time (JIT) inventory and safety stock, reducing stockouts while minimizing holding costs. Real-time demand forecasting powered by machine learning enables dynamic adjustment of safety stock levels, ensuring responsiveness to market fluctuations without excessive inventory buildup. The convergence of IoT-enabled supply chains and predictive analytics is driving more precise inventory strategies, aligning JIT responsiveness with strategic safety stock buffers to enhance overall operational efficiency.

just-in-time inventory vs safety stock Infographic

difterm.com

difterm.com