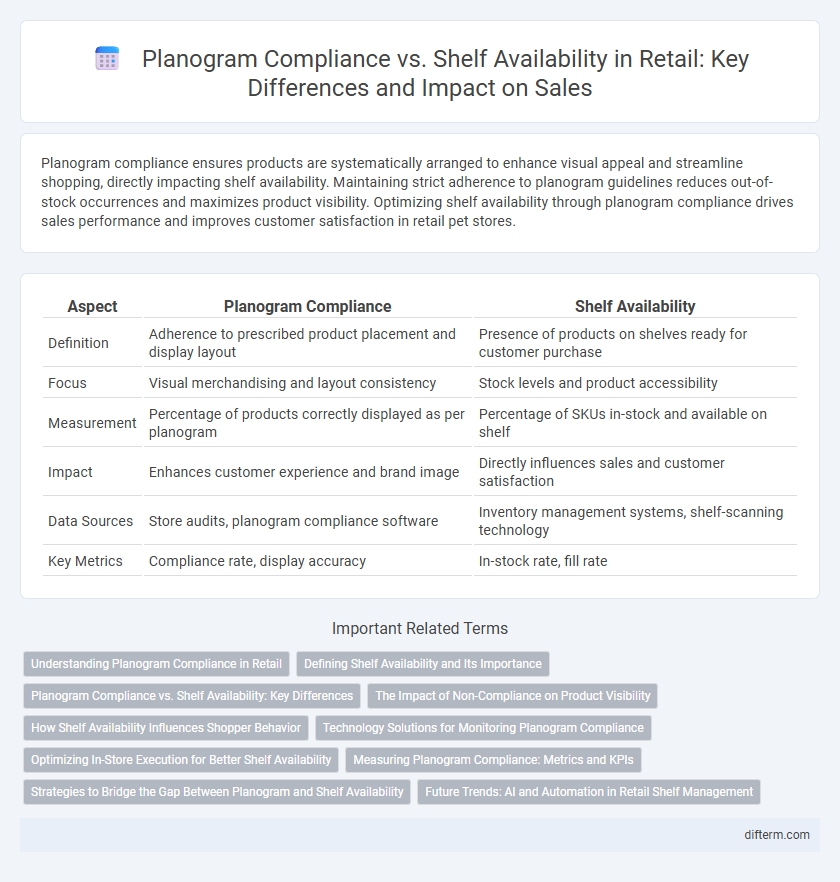

Planogram compliance ensures products are systematically arranged to enhance visual appeal and streamline shopping, directly impacting shelf availability. Maintaining strict adherence to planogram guidelines reduces out-of-stock occurrences and maximizes product visibility. Optimizing shelf availability through planogram compliance drives sales performance and improves customer satisfaction in retail pet stores.

Table of Comparison

| Aspect | Planogram Compliance | Shelf Availability |

|---|---|---|

| Definition | Adherence to prescribed product placement and display layout | Presence of products on shelves ready for customer purchase |

| Focus | Visual merchandising and layout consistency | Stock levels and product accessibility |

| Measurement | Percentage of products correctly displayed as per planogram | Percentage of SKUs in-stock and available on shelf |

| Impact | Enhances customer experience and brand image | Directly influences sales and customer satisfaction |

| Data Sources | Store audits, planogram compliance software | Inventory management systems, shelf-scanning technology |

| Key Metrics | Compliance rate, display accuracy | In-stock rate, fill rate |

Understanding Planogram Compliance in Retail

Planogram compliance in retail ensures that products are displayed according to predefined layouts, maximizing visual appeal and promoting optimal inventory placement. High planogram compliance directly improves shelf availability by reducing stockouts and facilitating efficient replenishment. Retailers leveraging planogram compliance data achieve better sales performance and enhanced customer shopping experiences through consistent product presentation.

Defining Shelf Availability and Its Importance

Shelf availability refers to the presence of products on retail shelves in the right quantities, locations, and conditions to meet consumer demand effectively. It ensures that customers find the desired items easily, minimizing lost sales and enhancing shopping experience. Maintaining high shelf availability is critical for optimizing inventory turnover, improving sales performance, and strengthening brand loyalty in competitive retail environments.

Planogram Compliance vs. Shelf Availability: Key Differences

Planogram compliance measures how well products are arranged according to a predetermined visual merchandising plan, ensuring optimal product placement and brand consistency on retail shelves. Shelf availability, however, focuses on the presence of products on shelves, emphasizing inventory levels and preventing out-of-stock situations that affect sales. While planogram compliance drives store aesthetics and shopper experience, shelf availability directly impacts product accessibility and consumer purchasing behavior.

The Impact of Non-Compliance on Product Visibility

Non-compliance with planogram standards significantly reduces shelf availability, leading to decreased product visibility and lost sales opportunities. When products are misplaced or missing according to the planogram, brands suffer from lower consumer engagement and impaired inventory management. Ensuring strict adherence to planogram layouts enhances visual appeal, optimizes shelf space, and drives revenue growth for retailers.

How Shelf Availability Influences Shopper Behavior

Shelf availability directly impacts shopper behavior by ensuring products are visible and accessible, which increases purchase likelihood and reduces lost sales due to out-of-stock items. Planogram compliance supports optimal shelf availability by maintaining the intended product assortment and placement, enhancing the shopping experience and encouraging brand loyalty. Inconsistent shelf availability often leads to customer frustration, diminished store perception, and decreased repeat visits.

Technology Solutions for Monitoring Planogram Compliance

Advanced technology solutions for monitoring planogram compliance leverage artificial intelligence and image recognition to ensure accurate shelf placement and product positioning. Real-time data analytics enable retailers to quickly identify discrepancies between planogram designs and actual shelf availability, optimizing restocking processes and enhancing customer satisfaction. Integration with mobile devices and IoT sensors further streamlines compliance tracking, reducing manual audits and improving operational efficiency across retail locations.

Optimizing In-Store Execution for Better Shelf Availability

Planogram compliance directly impacts shelf availability by ensuring products are placed according to the optimal layout that maximizes visibility and accessibility. Accurate adherence to planograms minimizes out-of-stock scenarios and improves inventory management by highlighting gaps promptly. Leveraging real-time shelf data and analytics enhances in-store execution, driving sales growth through consistent product presentation and replenishment.

Measuring Planogram Compliance: Metrics and KPIs

Measuring planogram compliance involves tracking key performance indicators such as shelf share percentage, product facings accuracy, and stock placement alignment to ensure optimal product visibility and merchandising standards. KPIs like out-of-stock rates, planogram adherence scores, and shelf capacity utilization directly impact shelf availability and overall retail performance. Accurate compliance measurement supports inventory optimization and enhances customer purchase experiences by maintaining consistent product availability on shelves.

Strategies to Bridge the Gap Between Planogram and Shelf Availability

Implement real-time inventory tracking systems to ensure accurate alignment between planogram specifications and actual shelf stock, reducing out-of-stock instances. Employ shelf-scanning technologies combined with AI analytics to identify discrepancies and optimize product placement dynamically. Train store associates on compliance protocols and integrate automated alerts to maintain planogram integrity and maximize shelf availability consistently.

Future Trends: AI and Automation in Retail Shelf Management

AI-driven planogram compliance tools enhance retail shelf management by automatically monitoring stock levels and ensuring product placement accuracy to maximize shelf availability. Automation technologies use real-time data analytics and computer vision to detect out-of-stock items and misplaced products, reducing manual auditing errors and improving inventory turnover. Future trends indicate widespread adoption of AI-powered robots and IoT sensors that optimize planogram adherence, boost shelf availability, and elevate the overall shopper experience.

planogram compliance vs shelf availability Infographic

difterm.com

difterm.com