RFID tagging offers real-time inventory tracking and enhanced accuracy compared to traditional barcode labeling, significantly reducing human error in retail pet stores. Unlike barcodes, RFID tags do not require a line-of-sight scan, enabling faster processing and better stock management for pet products. This advanced technology also improves loss prevention and customer experience by streamlining checkout and stock replenishment processes.

Table of Comparison

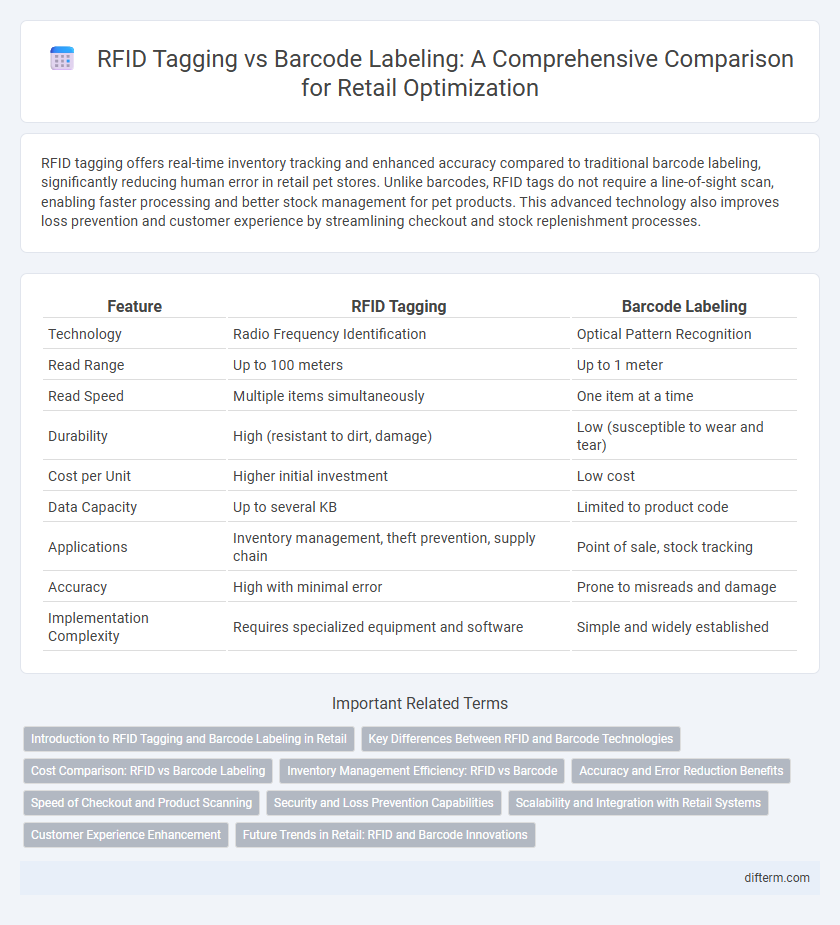

| Feature | RFID Tagging | Barcode Labeling |

|---|---|---|

| Technology | Radio Frequency Identification | Optical Pattern Recognition |

| Read Range | Up to 100 meters | Up to 1 meter |

| Read Speed | Multiple items simultaneously | One item at a time |

| Durability | High (resistant to dirt, damage) | Low (susceptible to wear and tear) |

| Cost per Unit | Higher initial investment | Low cost |

| Data Capacity | Up to several KB | Limited to product code |

| Applications | Inventory management, theft prevention, supply chain | Point of sale, stock tracking |

| Accuracy | High with minimal error | Prone to misreads and damage |

| Implementation Complexity | Requires specialized equipment and software | Simple and widely established |

Introduction to RFID Tagging and Barcode Labeling in Retail

RFID tagging in retail uses radio waves to automatically identify and track items, enabling faster inventory management and reducing human error compared to barcode labeling, which requires line-of-sight scanning. Barcode labeling remains widespread due to its low cost and simplicity but is limited by manual scanning processes and potential misreads. Integrating RFID technology enhances supply chain visibility and real-time stock monitoring, crucial for improving customer experience and operational efficiency.

Key Differences Between RFID and Barcode Technologies

RFID tagging utilizes radio waves to automatically identify and track items, enabling real-time inventory management without direct line of sight, whereas barcode labeling requires manual scanning with a laser or camera. RFID tags can store more data and withstand harsh environments, providing enhanced security and durability compared to barcodes. However, RFID systems involve higher implementation costs and complexity, while barcodes remain cost-effective and widely adopted for basic retail applications.

Cost Comparison: RFID vs Barcode Labeling

RFID tagging typically incurs higher initial costs due to expensive tags and reader infrastructure, while barcode labeling offers a more affordable setup with lower tag and scanner prices. However, RFID delivers faster scanning rates and reduces labor costs over time, potentially offsetting upfront expenses in large-scale retail operations. Barcode systems remain cost-effective for small businesses with limited inventory, making the choice dependent on inventory size and scanning efficiency needs.

Inventory Management Efficiency: RFID vs Barcode

RFID tagging significantly enhances inventory management efficiency by enabling real-time, automated tracking of products without direct line-of-sight, reducing human error and stock discrepancies. Barcode labeling, while cost-effective and widely implemented, requires manual scanning that slows down inventory processes and increases labor costs. Retailers leveraging RFID technology experience improved accuracy, faster stock replenishment, and streamlined supply chain visibility, which translate to better inventory turnover and reduced out-of-stock situations.

Accuracy and Error Reduction Benefits

RFID tagging significantly improves accuracy in retail inventory management by enabling real-time tracking and reducing human scanning errors compared to traditional barcode labeling. Unlike barcodes that require line-of-sight scanning, RFID tags can be read simultaneously and remotely, minimizing misreads and data discrepancies. This technology reduces stockouts and overstock situations, optimizing supply chain efficiency and customer satisfaction.

Speed of Checkout and Product Scanning

RFID tagging significantly accelerates checkout by enabling simultaneous scanning of multiple items without direct line-of-sight, reducing transaction times by up to 50% compared to barcode labeling. Barcode labeling requires individual scanning and precise alignment, often causing bottlenecks during peak retail hours. The enhanced scanning speed of RFID technology improves overall store efficiency and customer satisfaction by streamlining the purchasing process.

Security and Loss Prevention Capabilities

RFID tagging enhances retail security by enabling real-time tracking and automated inventory management, significantly reducing shrinkage caused by theft and misplacement. Unlike barcode labeling, RFID tags store encrypted data that is difficult to replicate or tamper with, providing superior protection against counterfeit and unauthorized access. Retailers using RFID experience improved loss prevention through continuous visibility and faster incident response compared to traditional barcode systems.

Scalability and Integration with Retail Systems

RFID tagging offers superior scalability in retail environments through bulk scanning capabilities, significantly reducing checkout times compared to barcode labeling, which requires line-of-sight scanning of individual items. Integration with retail systems is smoother with RFID due to its real-time inventory tracking and automated data capture, enabling seamless synchronization with POS, ERP, and supply chain management platforms. Barcode labeling, while cost-effective for small-scale operations, often demands manual data entry and slower update cycles, limiting its efficiency in large, complex retail ecosystems.

Customer Experience Enhancement

RFID tagging significantly enhances customer experience by enabling faster checkouts and real-time inventory accuracy, reducing out-of-stock scenarios. Unlike barcode labeling, RFID allows contactless scanning and bulk item processing, minimizing wait times and improving convenience. Retailers using RFID also benefit from enhanced product traceability, ensuring customers receive authentic and high-quality goods.

Future Trends in Retail: RFID and Barcode Innovations

RFID tagging is rapidly advancing with enhanced data storage, faster scanning capabilities, and improved accuracy, positioning it as a key technology in the future of retail inventory management. Barcode labeling continues to evolve through innovations like QR codes and printable electronics, offering cost-effective solutions for product tracking and customer engagement. Emerging trends include hybrid systems combining RFID and barcode technologies to optimize supply chain efficiency, real-time data analytics, and seamless omni-channel retail experiences.

RFID tagging vs Barcode labeling Infographic

difterm.com

difterm.com