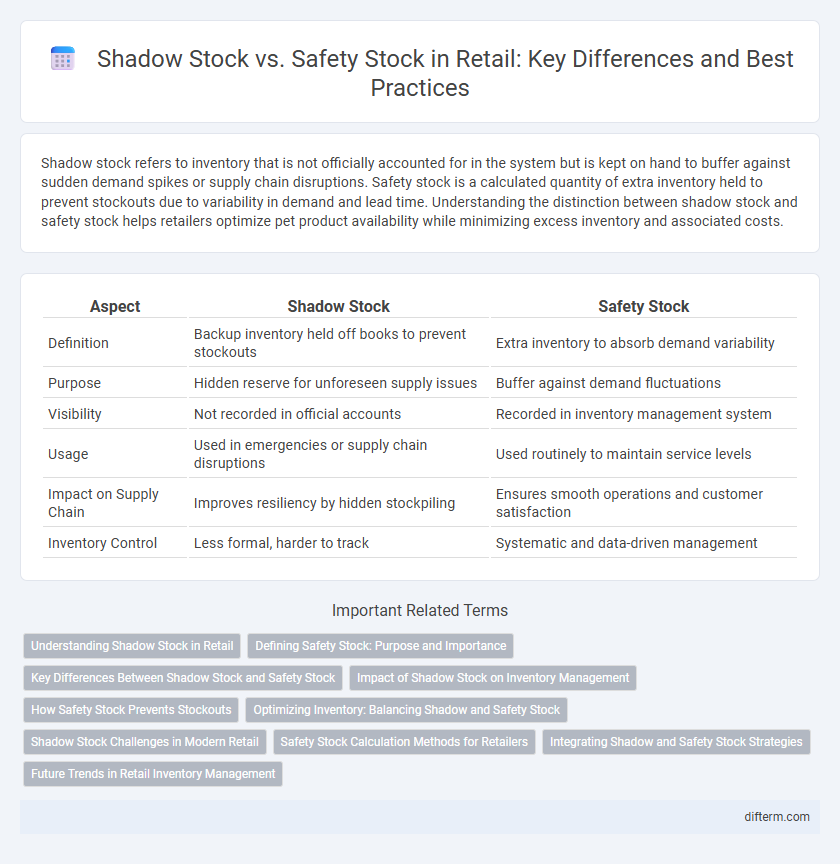

Shadow stock refers to inventory that is not officially accounted for in the system but is kept on hand to buffer against sudden demand spikes or supply chain disruptions. Safety stock is a calculated quantity of extra inventory held to prevent stockouts due to variability in demand and lead time. Understanding the distinction between shadow stock and safety stock helps retailers optimize pet product availability while minimizing excess inventory and associated costs.

Table of Comparison

| Aspect | Shadow Stock | Safety Stock |

|---|---|---|

| Definition | Backup inventory held off books to prevent stockouts | Extra inventory to absorb demand variability |

| Purpose | Hidden reserve for unforeseen supply issues | Buffer against demand fluctuations |

| Visibility | Not recorded in official accounts | Recorded in inventory management system |

| Usage | Used in emergencies or supply chain disruptions | Used routinely to maintain service levels |

| Impact on Supply Chain | Improves resiliency by hidden stockpiling | Ensures smooth operations and customer satisfaction |

| Inventory Control | Less formal, harder to track | Systematic and data-driven management |

Understanding Shadow Stock in Retail

Shadow stock in retail refers to inventory that exists unofficially or is not recorded in the main inventory management system, often held to buffer against supply chain disruptions or unanticipated demand spikes. Unlike safety stock, which is a calculated quantity of extra inventory to prevent stockouts, shadow stock is typically hidden or off-the-books, making it challenging to track and optimize. Understanding shadow stock helps retailers improve inventory accuracy, reduce carrying costs, and enhance overall supply chain transparency.

Defining Safety Stock: Purpose and Importance

Safety stock in retail refers to the extra inventory held to protect against uncertainties in demand and supply fluctuations, ensuring product availability and preventing stockouts. It acts as a buffer that maintains service levels during lead time variability or unexpected spikes in customer demand. Proper calculation and management of safety stock optimize inventory holding costs while minimizing lost sales and enhancing customer satisfaction.

Key Differences Between Shadow Stock and Safety Stock

Shadow stock represents surplus inventory recorded in accounting books but physically absent in the warehouse, used to manage expected stock discrepancies or lost items, while safety stock is a real buffer of inventory held to prevent stockouts due to demand fluctuations or supply delays. Shadow stock addresses internal accounting and inventory accuracy issues, whereas safety stock focuses on operational risk mitigation ensuring continuous product availability. The key difference lies in shadow stock being an accounting tool reflecting phantom inventory, while safety stock is a proactive physical quantity maintained to absorb supply chain uncertainties.

Impact of Shadow Stock on Inventory Management

Shadow stock significantly enhances inventory visibility by accounting for goods in transit and reserved quantities, allowing retailers to better forecast demand and reduce stockouts. Unlike safety stock, which serves as a buffer against uncertainty and supply chain disruptions, shadow stock provides real-time insight into actual inventory availability, improving replenishment accuracy. This dynamic adjustment of stock levels supports optimized order planning, minimizes excess inventory, and boosts overall supply chain efficiency.

How Safety Stock Prevents Stockouts

Safety stock acts as a critical buffer inventory in retail, safeguarding against stockouts caused by unpredictable demand fluctuations or supply chain delays. Unlike shadow stock, which represents unrecorded or hidden inventory, safety stock is intentionally calculated and maintained based on historical sales data and lead time variability. This proactive inventory management method ensures product availability, maintains customer satisfaction, and minimizes the risk of lost sales.

Optimizing Inventory: Balancing Shadow and Safety Stock

Optimizing inventory in retail requires balancing shadow stock--extra inventory held to mitigate supply chain uncertainties--and safety stock, which protects against demand variability. Effective inventory management leverages real-time sales data and supplier reliability metrics to determine optimal shadow and safety stock levels, minimizing holding costs while preventing stockouts. Advanced forecasting tools help retailers dynamically adjust these buffers, ensuring a seamless customer experience and improved cash flow.

Shadow Stock Challenges in Modern Retail

Shadow stock in modern retail presents significant challenges due to its untracked inventory that can distort demand forecasting and inventory management accuracy. Unlike safety stock, which acts as a deliberate buffer against uncertainties, shadow stock often results from errors, misplaced items, or theft, complicating stock visibility and leading to potential stockouts or overstocking. Retailers must invest in advanced inventory tracking technologies and data analytics to minimize shadow stock impact and maintain efficient supply chain operations.

Safety Stock Calculation Methods for Retailers

Safety stock calculation methods for retailers primarily include the statistical approach, which uses demand variability and lead time fluctuations to determine buffer inventory levels. The fixed safety stock formula calculates extra stock by multiplying the standard deviation of demand during the lead time by a service level factor derived from the desired service probability. Another method, the continuous review model, adjusts safety stock dynamically based on real-time sales data and supplier reliability, ensuring optimal inventory to prevent stockouts without overstocking.

Integrating Shadow and Safety Stock Strategies

Integrating shadow stock and safety stock strategies enhances retail inventory management by balancing demand variability and supply chain disruptions. Shadow stock provides a buffer of additional inventory stored in alternate locations, while safety stock acts as a reserve against unexpected demand spikes or delays. Combining these approaches optimizes stock availability, reduces stockouts, and improves overall customer satisfaction in retail operations.

Future Trends in Retail Inventory Management

Shadow stock and safety stock are evolving with the integration of AI-driven demand forecasting and real-time inventory tracking in retail. Future trends emphasize predictive analytics to optimize shadow stock levels, minimizing excess inventory while ensuring safety stock buffers respond dynamically to supply chain disruptions. Retailers leveraging IoT and blockchain technologies will achieve greater transparency and agility in managing both stock types, enhancing overall inventory efficiency.

Shadow Stock vs Safety Stock Infographic

difterm.com

difterm.com