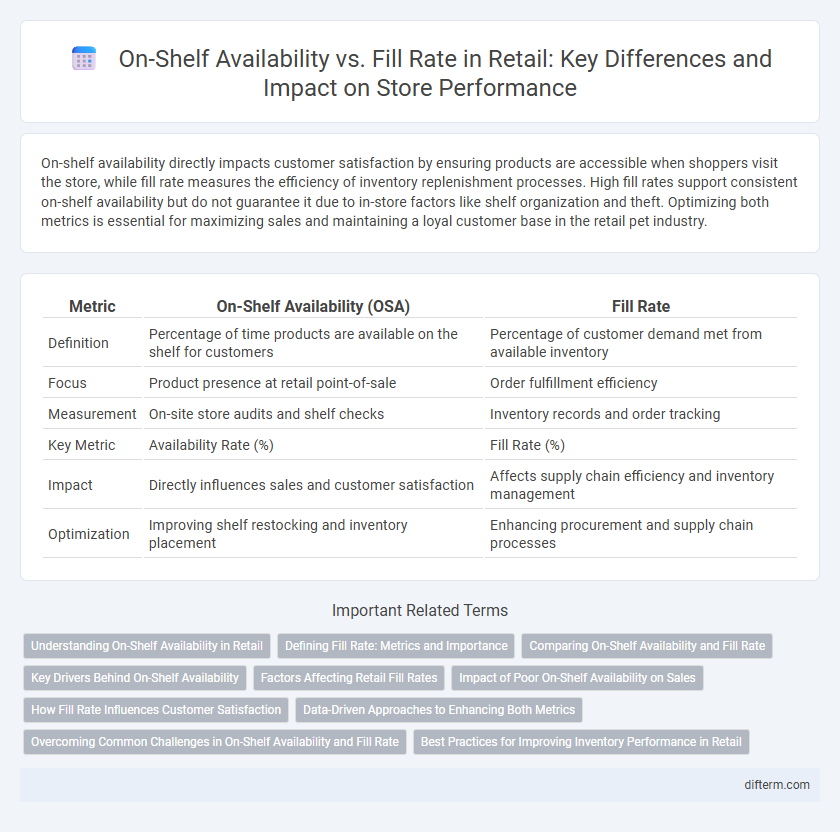

On-shelf availability directly impacts customer satisfaction by ensuring products are accessible when shoppers visit the store, while fill rate measures the efficiency of inventory replenishment processes. High fill rates support consistent on-shelf availability but do not guarantee it due to in-store factors like shelf organization and theft. Optimizing both metrics is essential for maximizing sales and maintaining a loyal customer base in the retail pet industry.

Table of Comparison

| Metric | On-Shelf Availability (OSA) | Fill Rate |

|---|---|---|

| Definition | Percentage of time products are available on the shelf for customers | Percentage of customer demand met from available inventory |

| Focus | Product presence at retail point-of-sale | Order fulfillment efficiency |

| Measurement | On-site store audits and shelf checks | Inventory records and order tracking |

| Key Metric | Availability Rate (%) | Fill Rate (%) |

| Impact | Directly influences sales and customer satisfaction | Affects supply chain efficiency and inventory management |

| Optimization | Improving shelf restocking and inventory placement | Enhancing procurement and supply chain processes |

Understanding On-Shelf Availability in Retail

On-shelf availability in retail measures the percentage of time products are physically present and purchasable by customers on store shelves, directly impacting sales and customer satisfaction. Unlike fill rate, which tracks the percentage of customer orders fulfilled from inventory, on-shelf availability focuses on real-time product presence at the point of sale. Optimizing on-shelf availability requires accurate demand forecasting, efficient inventory management, and timely replenishment to reduce stockouts and enhance retail performance.

Defining Fill Rate: Metrics and Importance

Fill rate in retail measures the percentage of customer demand met without stockouts, directly impacting on-shelf availability and sales performance. It indicates how effectively inventory meets actual consumer purchase requests, often calculated as units shipped divided by units ordered. High fill rates optimize product availability, reduce lost sales, and enhance customer satisfaction in competitive retail environments.

Comparing On-Shelf Availability and Fill Rate

On-shelf availability measures the percentage of products physically present on store shelves for customers, directly impacting sales and customer satisfaction. Fill rate quantifies the retailer's ability to meet product demand from inventory, reflecting supply chain efficiency and order fulfillment accuracy. Comparing the two, on-shelf availability highlights in-store product readiness, while fill rate emphasizes backend inventory management, both essential for optimizing retail performance and minimizing lost sales.

Key Drivers Behind On-Shelf Availability

On-shelf availability (OSA) is crucial for retail success and is primarily driven by accurate demand forecasting, efficient inventory management, and seamless supply chain coordination. Unlike fill rate, which measures the percentage of customer orders fulfilled from available stock, OSA focuses on ensuring the product is physically present and visible on the shelf when customers shop. Key drivers behind OSA include data-driven replenishment strategies, real-time shelf monitoring technologies, and collaboration between retailers and suppliers to prevent stockouts and maximize consumer satisfaction.

Factors Affecting Retail Fill Rates

Retail fill rates are significantly influenced by inventory accuracy, demand forecasting precision, and supply chain efficiency. Poor shelf replenishment practices and unexpected stockouts directly reduce on-shelf availability, leading to lost sales opportunities. Supplier reliability and lead time variability also play critical roles in maintaining optimal fill rates and ensuring consistent product availability for customers.

Impact of Poor On-Shelf Availability on Sales

Poor on-shelf availability directly reduces sales by causing missed purchase opportunities when products are not visible or accessible to customers. This leads to lower customer satisfaction and increased likelihood of shoppers switching to competitors, resulting in lost revenue. A low fill rate exacerbates out-of-stock situations, disrupting inventory flow and undermining supply chain efficiency.

How Fill Rate Influences Customer Satisfaction

Fill rate directly impacts on-shelf availability by ensuring products are consistently stocked, which enhances customer satisfaction through reliable access to desired items. High fill rates reduce stockouts and backorders, leading to fewer lost sales and improved shopper loyalty. Retailers maintaining optimal fill rates streamline inventory management, creating a seamless shopping experience that meets consumer expectations.

Data-Driven Approaches to Enhancing Both Metrics

Data-driven approaches to improving on-shelf availability and fill rate leverage real-time inventory analytics and predictive demand forecasting to minimize stockouts and overstocks. Advanced machine learning algorithms analyze sales patterns and supply chain data to optimize replenishment cycles and shelf stocking strategies. Integrating IoT sensors and automated restocking alerts further enhances accuracy, ensuring products are consistently available to meet customer demand.

Overcoming Common Challenges in On-Shelf Availability and Fill Rate

Improving on-shelf availability requires accurate demand forecasting and real-time inventory tracking to prevent stockouts and ensure products are consistently present for customers. Enhancing fill rate depends on seamless supply chain coordination and efficient order fulfillment processes that minimize delays and backorders. Leveraging data analytics and automated replenishment systems addresses common challenges by aligning inventory levels with customer demand, reducing lost sales and increasing retail profitability.

Best Practices for Improving Inventory Performance in Retail

Optimal on-shelf availability requires precise demand forecasting and real-time inventory tracking, enabling retailers to reduce stockouts and lost sales. Enhancing fill rate involves efficient supply chain collaboration and automated replenishment systems that minimize order delays and overstock situations. Employing data analytics and integrated inventory management software promotes synchronized stock levels, ensuring consistent product presence and maximizing customer satisfaction.

on-shelf availability vs fill rate Infographic

difterm.com

difterm.com