Retail pet stores benefit significantly from integrating MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems to streamline inventory management and operations. MRP focuses on optimizing stock levels and production schedules to meet customer demand efficiently, while ERP provides a comprehensive platform that unifies various business processes including sales, finance, and supply chain management. Comparing MRP versus ERP reveals ERP as a more holistic solution, crucial for pet retailers aiming to enhance productivity, reduce costs, and improve overall customer satisfaction.

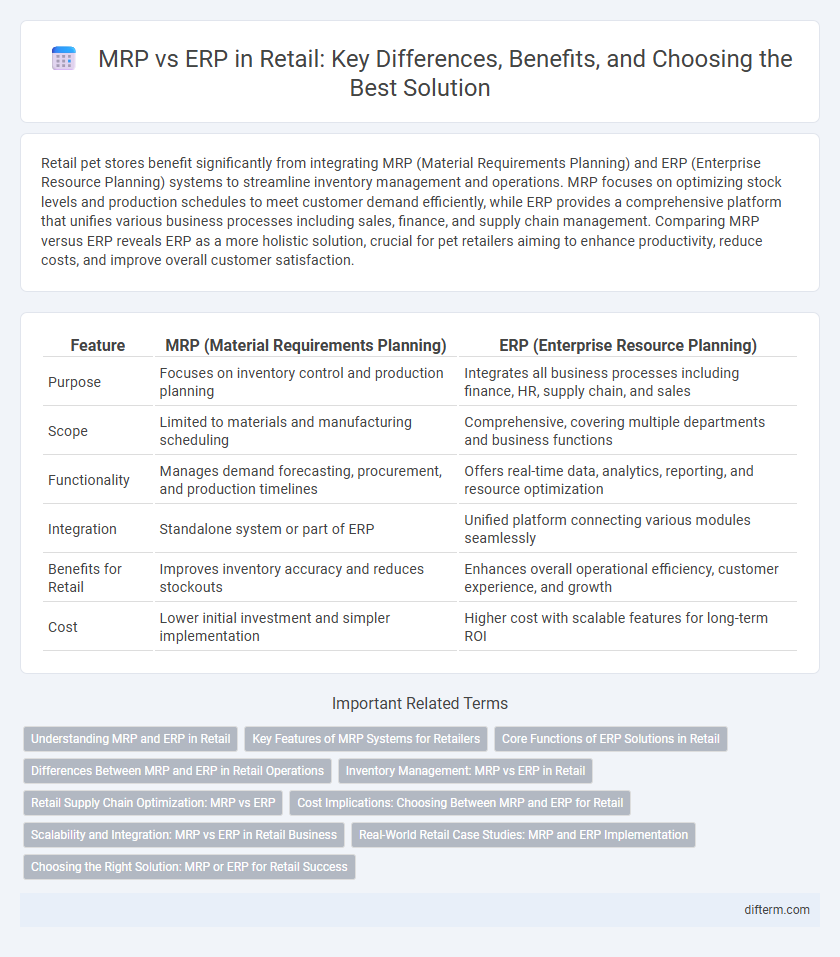

Table of Comparison

| Feature | MRP (Material Requirements Planning) | ERP (Enterprise Resource Planning) |

|---|---|---|

| Purpose | Focuses on inventory control and production planning | Integrates all business processes including finance, HR, supply chain, and sales |

| Scope | Limited to materials and manufacturing scheduling | Comprehensive, covering multiple departments and business functions |

| Functionality | Manages demand forecasting, procurement, and production timelines | Offers real-time data, analytics, reporting, and resource optimization |

| Integration | Standalone system or part of ERP | Unified platform connecting various modules seamlessly |

| Benefits for Retail | Improves inventory accuracy and reduces stockouts | Enhances overall operational efficiency, customer experience, and growth |

| Cost | Lower initial investment and simpler implementation | Higher cost with scalable features for long-term ROI |

Understanding MRP and ERP in Retail

Material Requirements Planning (MRP) in retail focuses on inventory control, demand forecasting, and ensuring product availability by managing order schedules and stock levels efficiently. Enterprise Resource Planning (ERP) integrates MRP functions with broader business processes such as finance, supply chain management, and customer relationship management to provide a comprehensive system for retail operations. Understanding the distinction and integration of MRP and ERP enables retailers to optimize inventory management, reduce costs, and enhance overall operational efficiency.

Key Features of MRP Systems for Retailers

MRP systems for retailers specialize in inventory management, demand forecasting, and supply chain coordination to ensure product availability and optimize stock levels. These systems automate reorder processes by analyzing sales data and lead times, reducing stockouts and excess inventory. Integration with point-of-sale (POS) systems enhances real-time data accuracy, supporting more efficient purchasing and merchandising decisions.

Core Functions of ERP Solutions in Retail

ERP solutions in retail streamline inventory management, automate procurement processes, and provide real-time sales analytics to optimize stock levels and enhance customer satisfaction. They integrate financial accounting, supply chain operations, and CRM systems to improve operational efficiency and decision-making accuracy. By consolidating data across departments, ERP platforms enable retailers to reduce costs, forecast demand, and accelerate order fulfillment.

Differences Between MRP and ERP in Retail Operations

MRP (Material Requirements Planning) in retail primarily focuses on inventory management, demand forecasting, and procurement scheduling to ensure stock availability. ERP (Enterprise Resource Planning) integrates MRP functions with broader business processes, including sales, finance, human resources, and customer relationship management, offering a comprehensive solution for retail operations. The key difference lies in MRP's specialization in materials planning versus ERP's ability to streamline and unify all retail operational areas into a single system.

Inventory Management: MRP vs ERP in Retail

Inventory management in retail leverages MRP (Material Requirements Planning) to optimize raw material procurement and production schedules, ensuring stock availability while minimizing excess inventory. ERP (Enterprise Resource Planning) systems offer a comprehensive solution by integrating inventory control with sales, finance, and supply chain management, enabling real-time visibility and enhanced decision-making. Retailers using ERP benefit from automated replenishment, demand forecasting, and multi-channel inventory synchronization, improving overall operational efficiency compared to standalone MRP systems.

Retail Supply Chain Optimization: MRP vs ERP

Retail supply chain optimization hinges on the effective integration of MRP and ERP systems. MRP (Material Requirements Planning) focuses on inventory control and demand forecasting to minimize stockouts and overstocks, streamlining procurement and production schedules. ERP (Enterprise Resource Planning) extends beyond MRP by unifying finance, sales, and warehouse management, providing end-to-end visibility and enabling data-driven decisions that enhance overall supply chain efficiency in retail operations.

Cost Implications: Choosing Between MRP and ERP for Retail

MRP systems primarily focus on inventory management and production scheduling, reducing costs related to overstocking and stockouts in retail operations. ERP solutions integrate multiple business functions beyond inventory, such as finance, sales, and customer relationship management, enabling comprehensive cost control and improved resource allocation. Investing in ERP typically incurs higher upfront costs but offers long-term savings through streamlined processes and data-driven decision-making in retail environments.

Scalability and Integration: MRP vs ERP in Retail Business

ERP systems in retail provide superior scalability by integrating multiple business functions such as inventory management, sales, and customer relationship management into a single platform, enabling seamless data flow and real-time analytics. MRP systems primarily focus on manufacturing resource planning, offering limited scalability and integration capabilities within retail operations. Retail businesses benefit from ERP solutions through enhanced operational efficiency, improved supply chain coordination, and the ability to accommodate business growth without system fragmentation.

Real-World Retail Case Studies: MRP and ERP Implementation

Real-world retail case studies demonstrate that MRP systems streamline inventory management and production schedules, resulting in reduced stockouts and improved order fulfillment. ERP implementations in retail integrate finance, supply chain, and customer relationship modules, enhancing data visibility and operational efficiency across multiple store locations. Retailers reported a 15-30% improvement in demand forecasting accuracy and a significant reduction in manual data entry errors after adopting these technologies.

Choosing the Right Solution: MRP or ERP for Retail Success

Selecting the right system between MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) is crucial for retail success, as MRP focuses mainly on inventory and production planning, while ERP offers a comprehensive solution integrating finance, sales, supply chain, and customer relationship management. Retail businesses with complex operations benefit from ERP systems due to their ability to unify data across departments, enabling better decision-making and improved efficiency. Evaluating specific retail needs such as inventory control, order management, and scalability helps determine whether the specialized capabilities of MRP or the broad functionality of ERP will drive optimal growth and profitability.

MRP vs ERP Infographic

difterm.com

difterm.com