Drop shipping in retail pet businesses reduces upfront investment and eliminates the need for storage space, allowing sellers to offer a wider range of products without holding inventory. Inventory holding provides greater control over stock quality, faster shipping times, and improved customer satisfaction through immediate product availability. Choosing between drop shipping and inventory holding depends on balancing cost efficiency with service reliability to optimize pet retail operations.

Table of Comparison

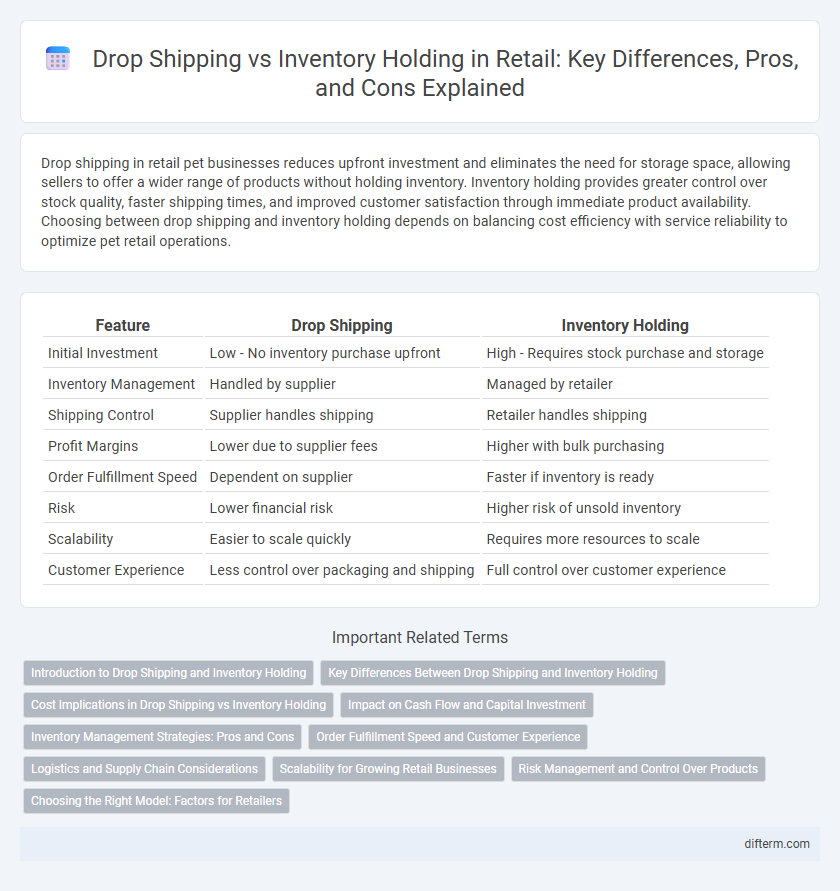

| Feature | Drop Shipping | Inventory Holding |

|---|---|---|

| Initial Investment | Low - No inventory purchase upfront | High - Requires stock purchase and storage |

| Inventory Management | Handled by supplier | Managed by retailer |

| Shipping Control | Supplier handles shipping | Retailer handles shipping |

| Profit Margins | Lower due to supplier fees | Higher with bulk purchasing |

| Order Fulfillment Speed | Dependent on supplier | Faster if inventory is ready |

| Risk | Lower financial risk | Higher risk of unsold inventory |

| Scalability | Easier to scale quickly | Requires more resources to scale |

| Customer Experience | Less control over packaging and shipping | Full control over customer experience |

Introduction to Drop Shipping and Inventory Holding

Drop shipping allows retailers to sell products without maintaining physical inventory, as orders are directly fulfilled by suppliers, reducing upfront costs and storage needs. Inventory holding requires retailers to purchase, store, and manage stock, providing faster order fulfillment and greater control over product availability but involves higher operational expenses. Choosing between these models depends on factors like cash flow, scalability, and customer service priorities.

Key Differences Between Drop Shipping and Inventory Holding

Drop shipping involves selling products without holding physical inventory, where retailers transfer customer orders directly to suppliers for fulfillment, minimizing upfront costs and storage risks. Inventory holding requires retailers to purchase and store products, enabling greater control over stock quality, faster shipping, and potential bulk purchase discounts. The key differences include capital investment, inventory risk, order fulfillment speed, and scalability potential in retail operations.

Cost Implications in Drop Shipping vs Inventory Holding

Drop shipping minimizes upfront inventory costs by eliminating the need to purchase and store products, reducing storage and handling expenses significantly. Inventory holding involves higher capital investment in purchasing stock and incurs ongoing costs for warehousing, insurance, and potential product obsolescence. Retailers using drop shipping benefit from lower financial risk, while inventory holding offers higher profit margins but demands more working capital and cost management.

Impact on Cash Flow and Capital Investment

Drop shipping minimizes capital investment by eliminating the need to stock inventory, allowing retailers to allocate cash flow more efficiently toward marketing and customer acquisition. Inventory holding requires significant upfront capital to purchase and store products, which can strain cash flow and increase holding costs such as warehousing and insurance. Optimizing cash flow through drop shipping reduces financial risk, while inventory holding offers better control over product availability and delivery speed, impacting capital allocation strategies in retail operations.

Inventory Management Strategies: Pros and Cons

Drop shipping eliminates the need for physical inventory, reducing upfront costs and storage risks but can lead to longer shipping times and less control over product quality. Inventory holding allows for faster order fulfillment and greater control over stock but requires significant investment in warehousing and carries the risk of unsold goods. Effective inventory management strategies must balance these trade-offs to optimize cash flow, customer satisfaction, and operational efficiency in retail.

Order Fulfillment Speed and Customer Experience

Drop shipping often results in longer order fulfillment times due to reliance on third-party suppliers, which can negatively impact customer experience with delayed deliveries and limited control over inventory accuracy. In contrast, inventory holding allows retailers to manage stock directly, enabling faster shipping and more reliable order tracking that enhance customer satisfaction. Efficient inventory management systems further optimize fulfillment speed, reducing errors and increasing consumer trust in delivery timelines.

Logistics and Supply Chain Considerations

Drop shipping reduces inventory holding costs by transferring logistics responsibilities to suppliers, enabling retailers to minimize warehousing and streamline order fulfillment. Inventory holding offers greater control over stock availability and shipping speed but requires significant investment in warehouse management and supply chain coordination. Efficient logistics in drop shipping depend on reliable supplier networks and real-time order tracking, whereas inventory holding relies on optimized inventory management systems to prevent stockouts and overstock situations.

Scalability for Growing Retail Businesses

Drop shipping offers unparalleled scalability for growing retail businesses by eliminating the need to manage physical inventory, allowing seamless expansion without significant upfront investment or storage constraints. Inventory holding requires substantial capital and space, limiting growth potential as businesses must balance stock levels to meet fluctuating demand. Leveraging drop shipping enables retailers to quickly adapt to market trends and scale product offerings efficiently, accelerating growth with reduced operational risks.

Risk Management and Control Over Products

Drop shipping minimizes inventory risk by eliminating the need to stock products, but it reduces control over product quality and delivery timelines, potentially affecting customer satisfaction. Inventory holding allows retailers to maintain full control over product quality, packaging, and shipping speed, mitigating risks related to supplier errors and delays. Effective risk management requires balancing the lower financial exposure of drop shipping with the greater operational control offered by inventory holding.

Choosing the Right Model: Factors for Retailers

Retailers must evaluate factors such as upfront investment, cash flow implications, and control over product quality when choosing between drop shipping and inventory holding models. Drop shipping minimizes inventory costs and reduces risk by shipping products directly from suppliers, while inventory holding offers faster fulfillment and better customer experience with immediate stock availability. Assessing target market demand, supplier reliability, and scalability goals helps retailers select the optimal fulfillment strategy for competitive advantage.

Drop Shipping vs Inventory Holding Infographic

difterm.com

difterm.com