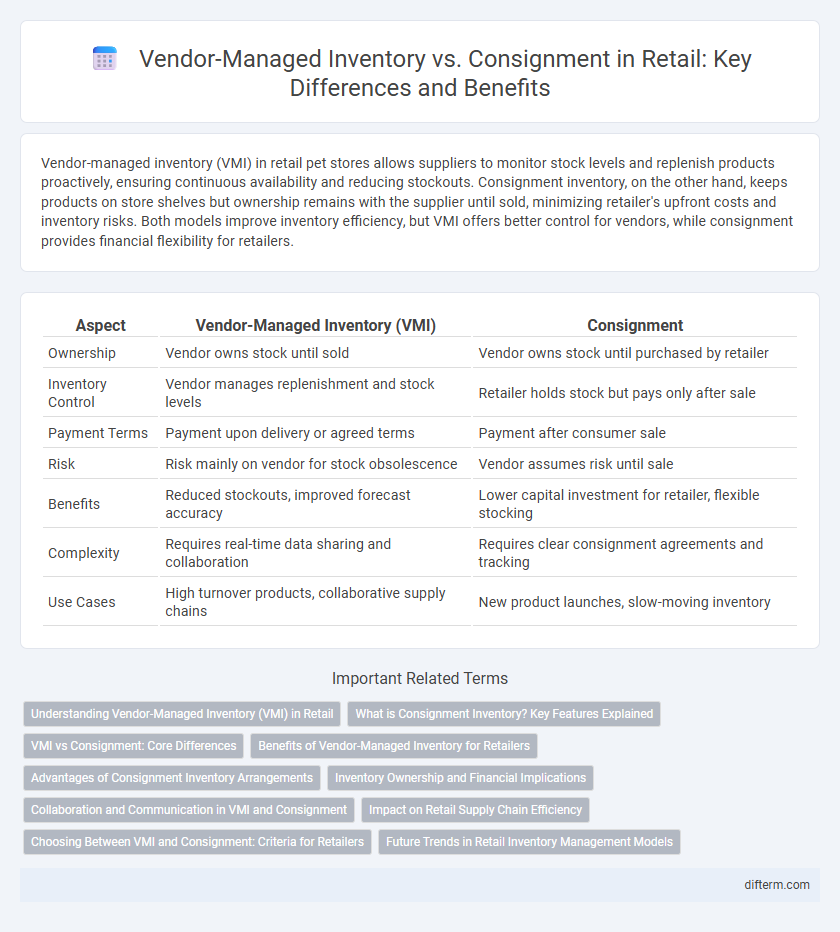

Vendor-managed inventory (VMI) in retail pet stores allows suppliers to monitor stock levels and replenish products proactively, ensuring continuous availability and reducing stockouts. Consignment inventory, on the other hand, keeps products on store shelves but ownership remains with the supplier until sold, minimizing retailer's upfront costs and inventory risks. Both models improve inventory efficiency, but VMI offers better control for vendors, while consignment provides financial flexibility for retailers.

Table of Comparison

| Aspect | Vendor-Managed Inventory (VMI) | Consignment |

|---|---|---|

| Ownership | Vendor owns stock until sold | Vendor owns stock until purchased by retailer |

| Inventory Control | Vendor manages replenishment and stock levels | Retailer holds stock but pays only after sale |

| Payment Terms | Payment upon delivery or agreed terms | Payment after consumer sale |

| Risk | Risk mainly on vendor for stock obsolescence | Vendor assumes risk until sale |

| Benefits | Reduced stockouts, improved forecast accuracy | Lower capital investment for retailer, flexible stocking |

| Complexity | Requires real-time data sharing and collaboration | Requires clear consignment agreements and tracking |

| Use Cases | High turnover products, collaborative supply chains | New product launches, slow-moving inventory |

Understanding Vendor-Managed Inventory (VMI) in Retail

Vendor-Managed Inventory (VMI) in retail streamlines supply chain efficiency by shifting inventory management responsibilities to vendors, enabling real-time stock replenishment based on actual sales data. This system contrasts with consignment, where the retailer holds inventory without ownership until sale, often leading to different financial and risk implications. Implementing VMI reduces stockouts and excess inventory, improving product availability and enhancing vendor-retailer collaboration.

What is Consignment Inventory? Key Features Explained

Consignment inventory is a retail stock management strategy where the supplier retains ownership of the goods until they are sold by the retailer, minimizing the retailer's upfront investment. Key features include reduced financial risk for retailers, improved cash flow management, and enhanced supplier-retailer collaboration through shared inventory visibility. This approach contrasts with vendor-managed inventory, where the supplier controls stock levels but ownership typically transfers upon delivery.

VMI vs Consignment: Core Differences

Vendor-managed inventory (VMI) and consignment differ fundamentally in ownership and responsibility; VMI places inventory ownership and replenishment responsibility on the vendor, while consignment keeps ownership with the vendor but stores goods at the retailer's location until sold. VMI fosters continuous collaboration with automated stock monitoring, reducing stockouts and excess inventory, whereas consignment reduces retailer risk with delayed payment but may limit stock visibility. These core differences impact cash flow, inventory control, and supply chain efficiency in retail operations.

Benefits of Vendor-Managed Inventory for Retailers

Vendor-managed inventory (VMI) enhances retail efficiency by transferring inventory management responsibility to suppliers, reducing stockouts and minimizing excess inventory costs. Retailers benefit from improved demand forecasting and replenishment accuracy, leading to optimized shelf availability and increased sales. VMI also fosters stronger supplier-retailer collaboration, streamlining supply chain operations and reducing administrative overhead.

Advantages of Consignment Inventory Arrangements

Consignment inventory arrangements enable retailers to reduce capital investment by holding stock without immediate payment, improving cash flow management significantly. Vendors retain ownership of the goods until they are sold, minimizing retailer risk related to excess or unsold inventory. This model enhances supply chain collaboration, leading to better inventory turnover rates and increased product availability for customers.

Inventory Ownership and Financial Implications

Vendor-managed inventory (VMI) places inventory ownership on the supplier until products are sold, reducing the retailer's holding costs and minimizing stockouts through supplier-driven replenishment. In consignment agreements, inventory remains the vendor's property in the retailer's premises, with payment only occurring after product sale, which lowers financial risk for retailers but can increase supplier's capital tied up in inventory. Financially, VMI improves cash flow for retailers by shifting inventory management burden to suppliers, while consignment shifts the risk of unsold stock entirely onto vendors, impacting their working capital requirements.

Collaboration and Communication in VMI and Consignment

Vendor-managed inventory (VMI) requires seamless collaboration and real-time communication between retailers and suppliers to optimize stock levels and reduce stockouts. In consignment models, effective information sharing ensures inventory ownership remains with vendors until sale, demanding transparent data exchange on sales and stock status. Both approaches leverage integrated communication systems to synchronize demand forecasting, order replenishment, and inventory visibility, enhancing supply chain responsiveness and retailer-supplier partnerships.

Impact on Retail Supply Chain Efficiency

Vendor-managed inventory (VMI) streamlines retail supply chains by shifting inventory control to suppliers, reducing stockouts and improving order accuracy through real-time data sharing. Consignment inventory allows retailers to minimize capital investment and decrease inventory holding costs while maintaining product availability on shelves. Both models enhance supply chain efficiency by optimizing inventory turnover and fostering closer collaboration between retailers and vendors.

Choosing Between VMI and Consignment: Criteria for Retailers

Retailers should evaluate vendor-managed inventory (VMI) and consignment based on inventory control, risk allocation, and cash flow impact. VMI offers suppliers control over stock levels, reducing stockouts and overstock risks for retailers, while consignment shifts inventory ownership to suppliers until sale, minimizing retailer capital investment but potentially increasing complexity in sales tracking. Key criteria include demand variability, supplier reliability, and financial terms to determine the optimal inventory management strategy.

Future Trends in Retail Inventory Management Models

Vendor-managed inventory (VMI) is evolving through advanced data analytics and AI integration, enabling real-time stock optimization and seamless supply chain collaboration. Consignment models are shifting towards hybrid frameworks where retailers maintain ownership control while leveraging vendor insights for dynamic inventory replenishment. Future trends emphasize automation, enhanced transparency, and AI-driven forecasting to minimize stockouts and reduce carrying costs in retail inventory management.

vendor-managed inventory vs consignment Infographic

difterm.com

difterm.com