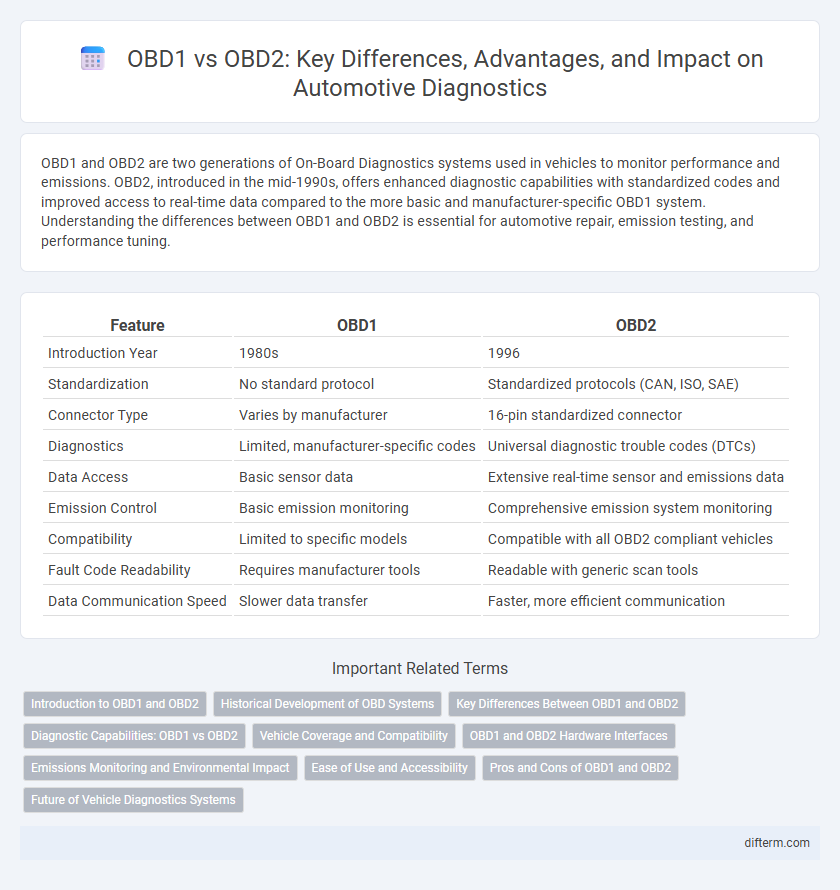

OBD1 and OBD2 are two generations of On-Board Diagnostics systems used in vehicles to monitor performance and emissions. OBD2, introduced in the mid-1990s, offers enhanced diagnostic capabilities with standardized codes and improved access to real-time data compared to the more basic and manufacturer-specific OBD1 system. Understanding the differences between OBD1 and OBD2 is essential for automotive repair, emission testing, and performance tuning.

Table of Comparison

| Feature | OBD1 | OBD2 |

|---|---|---|

| Introduction Year | 1980s | 1996 |

| Standardization | No standard protocol | Standardized protocols (CAN, ISO, SAE) |

| Connector Type | Varies by manufacturer | 16-pin standardized connector |

| Diagnostics | Limited, manufacturer-specific codes | Universal diagnostic trouble codes (DTCs) |

| Data Access | Basic sensor data | Extensive real-time sensor and emissions data |

| Emission Control | Basic emission monitoring | Comprehensive emission system monitoring |

| Compatibility | Limited to specific models | Compatible with all OBD2 compliant vehicles |

| Fault Code Readability | Requires manufacturer tools | Readable with generic scan tools |

| Data Communication Speed | Slower data transfer | Faster, more efficient communication |

Introduction to OBD1 and OBD2

On-board diagnostics (OBD) systems monitor vehicle emissions, engine performance, and other critical functions; OBD1, introduced in the early 1980s, offered basic diagnostic information through manufacturer-specific protocols and limited standardized codes. OBD2, mandated in the United States since 1996, provides enhanced diagnostics with a standardized 16-pin connector, broader sensor data access, and universal trouble codes, enabling advanced emission control and more precise engine fault detection. These systems support technicians and car owners in efficient troubleshooting and regulatory compliance across diverse automotive makes and models.

Historical Development of OBD Systems

OBD1 systems emerged in the early 1980s as basic diagnostic tools, primarily designed to monitor engine performance and emissions controls in manufacturer-specific formats. OBD2, introduced by the mid-1990s regulatory mandates such as the U.S. EPA's Clean Air Act and California Air Resources Board (CARB) requirements, standardized diagnostic trouble codes and protocols across all vehicles, enhancing compatibility and data accessibility. This evolution from OBD1 to OBD2 significantly improved emissions monitoring, fault detection precision, and facilitated advanced onboard diagnostics integration.

Key Differences Between OBD1 and OBD2

OBD1 systems, introduced in the early 1980s, use manufacturer-specific protocols and connectors, limiting compatibility and diagnostic capabilities compared to OBD2 systems standardized in 1996. OBD2 offers universal connector designs and a broader range of diagnostic trouble codes (DTCs), enabling comprehensive vehicle monitoring and emissions control. Enhanced real-time data access and improved communication protocols in OBD2 support advanced diagnostics and regulatory compliance across all vehicle makes and models.

Diagnostic Capabilities: OBD1 vs OBD2

OBD1 systems provide basic diagnostic trouble codes that require manual interpretation, limiting their ability to identify specific engine and emission issues, while OBD2 offers standardized, comprehensive diagnostics with real-time data stream access and enhanced fault detection across all vehicle systems. OBD2 supports a wider range of sensors and monitors critical parameters such as oxygen sensors, catalytic converters, and evaporative emissions, enabling precise fault isolation and proactive maintenance. The advanced diagnostic capabilities of OBD2 facilitate faster troubleshooting and improved compliance with emission standards compared to the more rudimentary and proprietary nature of OBD1.

Vehicle Coverage and Compatibility

OBD1 systems, primarily used in vehicles manufactured before 1996, offer limited vehicle coverage and are often specific to individual manufacturers, resulting in reduced compatibility with universal diagnostic tools. In contrast, OBD2, mandated for all cars and light trucks built after 1996, provides standardized protocols that support extensive vehicle coverage across makes and models, enhancing compatibility with a wide range of diagnostic scanners. This uniformity in OBD2 enables more comprehensive diagnostics, emissions monitoring, and interoperability within modern automotive systems.

OBD1 and OBD2 Hardware Interfaces

OBD1 hardware interfaces consist of proprietary connectors and communication protocols unique to each vehicle manufacturer, often requiring specific adapters for diagnostic access. OBD2 introduced a standardized 16-pin connector and uniform communication protocols such as CAN, ISO 9141, and KWP2000, enabling universal scanner compatibility across all compliant vehicles. The shift from OBD1's manufacturer-specific interfaces to OBD2's standardized hardware significantly improved diagnostic tool interoperability and data accessibility.

Emissions Monitoring and Environmental Impact

OBD2 systems provide more comprehensive emissions monitoring compared to OBD1 by continuously tracking a wider range of engine and emissions control components, enabling quicker detection and diagnosis of faults that increase pollution. This real-time data collection helps maintain vehicles in optimal condition, significantly reducing harmful emissions such as carbon monoxide, hydrocarbons, and nitrogen oxides. Enhanced OBD2 capabilities support stricter environmental regulations and contribute to improved air quality and decreased environmental impact globally.

Ease of Use and Accessibility

OBD2 systems offer greater ease of use and accessibility compared to OBD1 by providing standardized diagnostic connectors and protocols across all vehicles manufactured after 1996. Unlike OBD1, which requires manufacturer-specific tools and manual lookup of error codes, OBD2 enables quick, universal access to live data and diagnostic trouble codes using affordable scanners. This standardization reduces diagnostic time and simplifies maintenance for both professional mechanics and vehicle owners.

Pros and Cons of OBD1 and OBD2

OBD1 provides basic diagnostic capabilities with manufacturer-specific protocols, making it simpler but less versatile for modern repairs. OBD2 offers standardized communication across all vehicles post-1996, enabling comprehensive diagnostics and real-time data monitoring with enhanced accuracy. However, OBD2 requires more complex hardware and software, which can increase costs and complexity for mechanics and users.

Future of Vehicle Diagnostics Systems

Future vehicle diagnostics systems will evolve beyond OBD1 and OBD2 by integrating advanced telematics, real-time data analytics, and AI-driven predictive maintenance. Unlike the basic fault codes of OBD1 and the standardized protocols of OBD2, next-generation systems will provide continuous monitoring and remote diagnostics through cloud connectivity. These innovations promise enhanced vehicle performance, reduced downtime, and proactive safety management.

OBD1 vs OBD2 Infographic

difterm.com

difterm.com