Torsen differentials use worm gears to provide torque-sensing capabilities, offering superior traction and durability in various driving conditions compared to helical differentials. Helical differentials rely on angled gears to distribute torque smoothly between wheels, improving handling and reducing wheel slip but with slightly less direct torque biasing than Torsen types. Choosing between a Torsen and a helical differential depends on the balance of performance needs, with Torsen favored for aggressive traction control and helical preferred for everyday driving comfort.

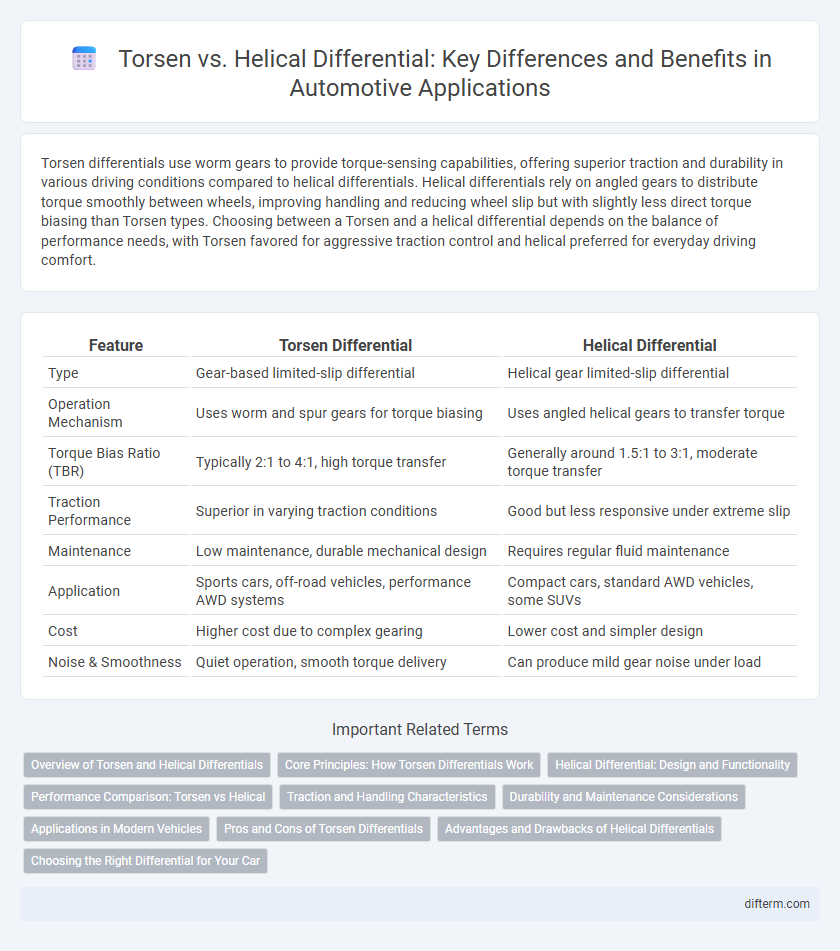

Table of Comparison

| Feature | Torsen Differential | Helical Differential |

|---|---|---|

| Type | Gear-based limited-slip differential | Helical gear limited-slip differential |

| Operation Mechanism | Uses worm and spur gears for torque biasing | Uses angled helical gears to transfer torque |

| Torque Bias Ratio (TBR) | Typically 2:1 to 4:1, high torque transfer | Generally around 1.5:1 to 3:1, moderate torque transfer |

| Traction Performance | Superior in varying traction conditions | Good but less responsive under extreme slip |

| Maintenance | Low maintenance, durable mechanical design | Requires regular fluid maintenance |

| Application | Sports cars, off-road vehicles, performance AWD systems | Compact cars, standard AWD vehicles, some SUVs |

| Cost | Higher cost due to complex gearing | Lower cost and simpler design |

| Noise & Smoothness | Quiet operation, smooth torque delivery | Can produce mild gear noise under load |

Overview of Torsen and Helical Differentials

Torsen differentials utilize helical gears to distribute torque continuously and proportionally between wheels, enhancing traction without electronic intervention. Helical differentials rely on spiral bevel gears providing smooth, quiet operation and balanced torque transfer, often favored in front-wheel-drive vehicles. Both types improve vehicle handling by dynamically adjusting torque distribution based on wheel grip conditions.

Core Principles: How Torsen Differentials Work

Torsen differentials operate using a set of helical gears that provide variable torque distribution between wheels based on traction conditions, enhancing vehicle stability and performance. Unlike traditional open differentials, Torsen units react mechanically to torque bias, redirecting power to the wheel with greater grip without electronic intervention. This gear-driven system improves cornering precision and traction control, making it a preferred choice in high-performance and off-road automotive applications.

Helical Differential: Design and Functionality

Helical differentials utilize angled helical gears to distribute torque smoothly between wheels while maintaining traction on varying surfaces. Their design allows for automatic torque biasing without the need for electronic controls, enhancing stability and handling during cornering. This gear arrangement reduces noise and wear compared to traditional gear types, making helical differentials a durable choice for performance and off-road vehicles.

Performance Comparison: Torsen vs Helical

Torsen differentials deliver superior torque distribution and faster response times due to their worm-gear design, enhancing traction in high-performance and off-road vehicles. Helical differentials use angled gears to provide smoother torque transfer and quieter operation but may lag in handling abrupt torque changes. Performance-wise, Torsen systems excel in dynamic driving conditions with higher torque bias ratios, while helical differentials prioritize durability and quieter function during regular road use.

Traction and Handling Characteristics

Torsen differentials provide superior traction by automatically distributing torque to the wheel with more grip, enhancing handling on varied road surfaces. Helical differentials also improve traction through gear design that allows smooth power transfer, but they tend to offer more predictable handling under high-speed cornering. Both types optimize vehicle stability, yet Torsen units excel in off-road and low-traction conditions due to their torque-sensing capabilities.

Durability and Maintenance Considerations

Torsen differentials offer superior durability due to their robust worm gear design, which provides consistent torque distribution under high stress and reduces wear over time. Helical differentials, while smoother in operation, often require more frequent maintenance because their gear engagement can lead to increased friction and heat buildup. Choosing between the two depends on the vehicle's intended use, with Torsen favored in high-performance or off-road applications for longevity and lower maintenance demands.

Applications in Modern Vehicles

Torsen differentials are widely used in high-performance and all-wheel-drive vehicles due to their ability to provide dynamic torque distribution and enhanced traction on varying surfaces. Helical differentials are common in front-wheel-drive and some all-wheel-drive vehicles, offering smooth torque transfer with quieter operation and improved fuel efficiency. Modern vehicles leverage Torsen differentials for sporty handling and off-road capability, while helical designs prioritize comfort and efficiency in everyday driving conditions.

Pros and Cons of Torsen Differentials

Torsen differentials provide superior torque distribution by automatically adjusting power transfer based on traction conditions, enhancing cornering stability and off-road performance. They offer faster response and improved durability compared to helical differentials, which rely on gear design rather than friction. However, Torsen differentials can be more complex and costly to manufacture, and may perform less effectively when one wheel is completely off the ground due to their dependence on torque biasing.

Advantages and Drawbacks of Helical Differentials

Helical differentials offer smooth torque distribution and enhanced traction under varying road conditions, making them ideal for performance and all-wheel-drive vehicles. Their primary advantage lies in reducing wheel slip by automatically adjusting torque between wheels without electronic intervention. However, helical differentials may exhibit slightly less precision in torque biasing compared to Torsen differentials, and they can produce more gear noise under heavy loads.

Choosing the Right Differential for Your Car

Choosing the right differential for your car depends on performance needs and driving conditions; Torsen differentials offer superior torque biasing and immediate response for off-road and high-performance applications, while helical differentials provide smoother operation and better traction in everyday driving. Torsen differentials use worm gears to distribute torque dynamically between wheels, enhancing cornering stability and grip under varied load conditions. Helical differentials rely on angled gears that deliver consistent traction without sudden shifts, making them ideal for street driving and moderate all-wheel-drive systems.

Torsen vs Helical Differential Infographic

difterm.com

difterm.com