Staged turbo systems use multiple turbochargers that activate sequentially, optimizing boost delivery at different engine speeds for improved power and efficiency. Compound turbo setups combine two turbochargers simultaneously to compress intake air more effectively, resulting in significant power gains but increased complexity. Understanding the differences between staged and compound turbocharging is essential for automotive enthusiasts seeking to enhance engine performance based on driving needs and budget.

Table of Comparison

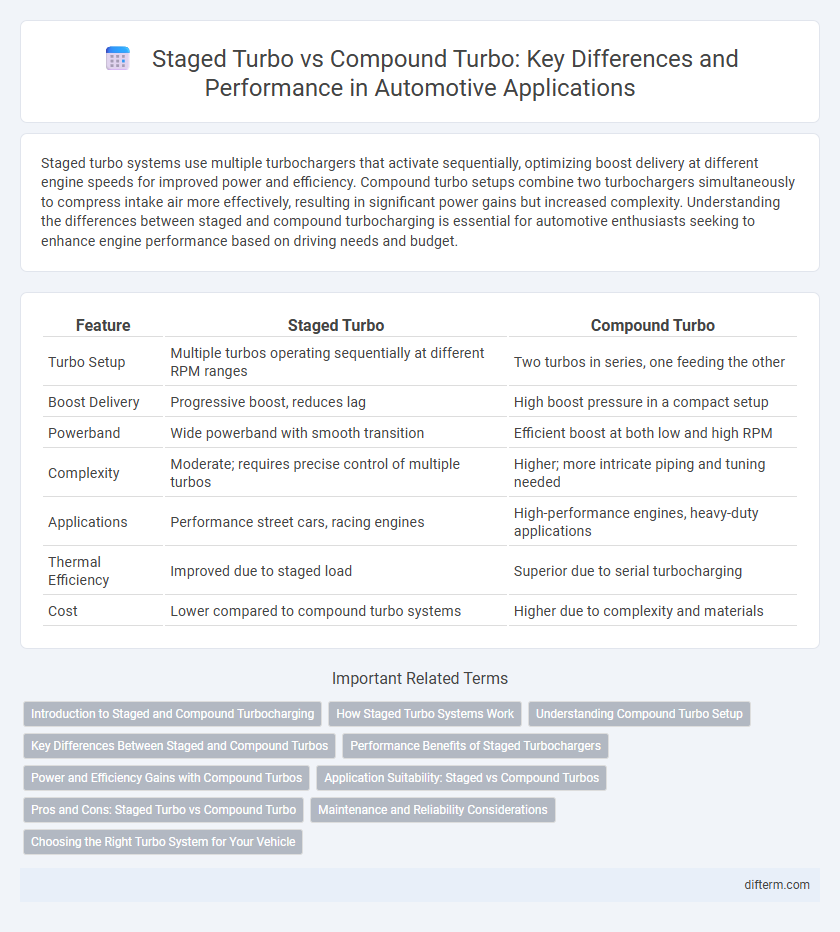

| Feature | Staged Turbo | Compound Turbo |

|---|---|---|

| Turbo Setup | Multiple turbos operating sequentially at different RPM ranges | Two turbos in series, one feeding the other |

| Boost Delivery | Progressive boost, reduces lag | High boost pressure in a compact setup |

| Powerband | Wide powerband with smooth transition | Efficient boost at both low and high RPM |

| Complexity | Moderate; requires precise control of multiple turbos | Higher; more intricate piping and tuning needed |

| Applications | Performance street cars, racing engines | High-performance engines, heavy-duty applications |

| Thermal Efficiency | Improved due to staged load | Superior due to serial turbocharging |

| Cost | Lower compared to compound turbo systems | Higher due to complexity and materials |

Introduction to Staged and Compound Turbocharging

Staged turbocharging uses two or more turbochargers that operate sequentially, optimizing boost pressure at varying engine speeds for improved efficiency and reduced lag. Compound turbocharging combines a high-pressure and a low-pressure turbo in series to maximize airflow and achieve higher boost pressures than single-stage systems. Both methods enhance engine performance but differ in complexity, response characteristics, and application suitability in modern automotive engines.

How Staged Turbo Systems Work

Staged turbo systems operate by using two or more turbochargers sequentially to optimize engine performance across different RPM ranges, with a smaller turbo providing quick boost at low RPMs and a larger turbo delivering increased airflow at higher RPMs. The primary turbine spool activates first to reduce turbo lag, while the secondary turbo spool engages as engine speed rises, ensuring consistent power delivery and improved efficiency. This configuration enhances throttle response and expands the torque curve compared to single or compound turbo setups.

Understanding Compound Turbo Setup

Compound turbo setups utilize two turbochargers of different sizes working in series to optimize boost pressure across a wide RPM range, enhancing engine performance and responsiveness. Unlike staged turbo systems that switch between turbos at predefined thresholds, compound turbos continuously blend the output of both units to minimize turbo lag and maximize efficiency. This configuration is especially effective in high-performance automotive applications where maintaining consistent power delivery is critical.

Key Differences Between Staged and Compound Turbos

Staged turbos use multiple turbochargers of different sizes activated sequentially to improve low-end torque and high-end power, optimizing engine efficiency across RPM ranges. Compound turbos, also called series turbos, connect two turbos in sequence where the smaller turbo feeds compressed air into the larger one, maximizing boost pressure and overall power output. Key differences include the staged turbo's focus on multi-speed boost control versus the compound turbo's emphasis on achieving higher final boost levels through serial compression.

Performance Benefits of Staged Turbochargers

Staged turbochargers enhance performance by optimizing boost pressure across a broader RPM range, delivering improved low-end torque and high-end power. This setup minimizes turbo lag through sequential activation, ensuring smoother power delivery and increased engine efficiency. Compared to compound turbos, staged turbos offer greater flexibility in tuning and better adaptability for varied driving conditions.

Power and Efficiency Gains with Compound Turbos

Compound turbocharging delivers superior power and efficiency gains by utilizing two differently sized turbochargers that operate sequentially, optimizing boost pressure across a wider RPM range compared to staged turbos. This setup reduces turbo lag and improves low-end torque while maintaining high-end power, resulting in enhanced overall engine performance and fuel efficiency. Advanced compound systems also enable better thermal management and reduced exhaust backpressure, further maximizing engine output and minimizing emissions.

Application Suitability: Staged vs Compound Turbos

Staged turbos excel in applications requiring a wide torque band and smooth power delivery, making them ideal for daily-driven vehicles and varied driving conditions. Compound turbos provide superior peak power and efficiency at high RPMs, suiting high-performance race cars and turbocharged diesel engines demanding maximum boost pressure. Selecting between staged and compound turbo setups depends on vehicle usage, desired power characteristics, and engine response priorities.

Pros and Cons: Staged Turbo vs Compound Turbo

Staged turbo systems use sequential turbos to optimize boost at different RPM ranges, offering improved low-end torque and high-end power, but they add complexity and can suffer from lag during transition. Compound turbo setups, where turbos operate in series, provide higher overall efficiency and sustained boost pressure, ideal for high-performance applications, though they require precise tuning and increase thermal stress on components. Choosing between staged and compound turbos depends on the desired performance characteristics, vehicle application, and acceptable maintenance demands.

Maintenance and Reliability Considerations

Staged turbo systems generally offer simpler maintenance due to their sequential activation and lower thermal stress on each turbocharger, enhancing overall reliability. Compound turbo setups, while providing higher performance gains, require more complex maintenance routines because of increased components and the constant high-pressure operation that can accelerate wear. Choosing between staged and compound turbos depends on balancing performance needs with the cost and frequency of maintenance to ensure long-term engine durability.

Choosing the Right Turbo System for Your Vehicle

Staged turbo systems utilize multiple turbochargers of different sizes operating sequentially to optimize boost across a wide RPM range, enhancing low-end torque and high-end power for daily driving and performance balance. Compound turbo setups use two turbochargers that work simultaneously, combining their pressure and efficiency to achieve higher boost levels ideal for high-performance or heavy-duty vehicles requiring maximum power output. Selecting the right turbo system depends on your vehicle's intended use, engine characteristics, and desired power delivery, with staged turbo offering versatility and compound turbo focusing on peak power gains.

staged turbo vs compound turbo Infographic

difterm.com

difterm.com