Torque vectoring enhances vehicle handling by actively distributing torque between wheels based on driving conditions, improving cornering and stability. Limited-slip differentials mechanically limit wheel spin by transferring torque to the wheel with traction, offering consistent grip on slippery surfaces. Compared to limited-slip differentials, torque vectoring provides more precise control and better performance in dynamic driving scenarios.

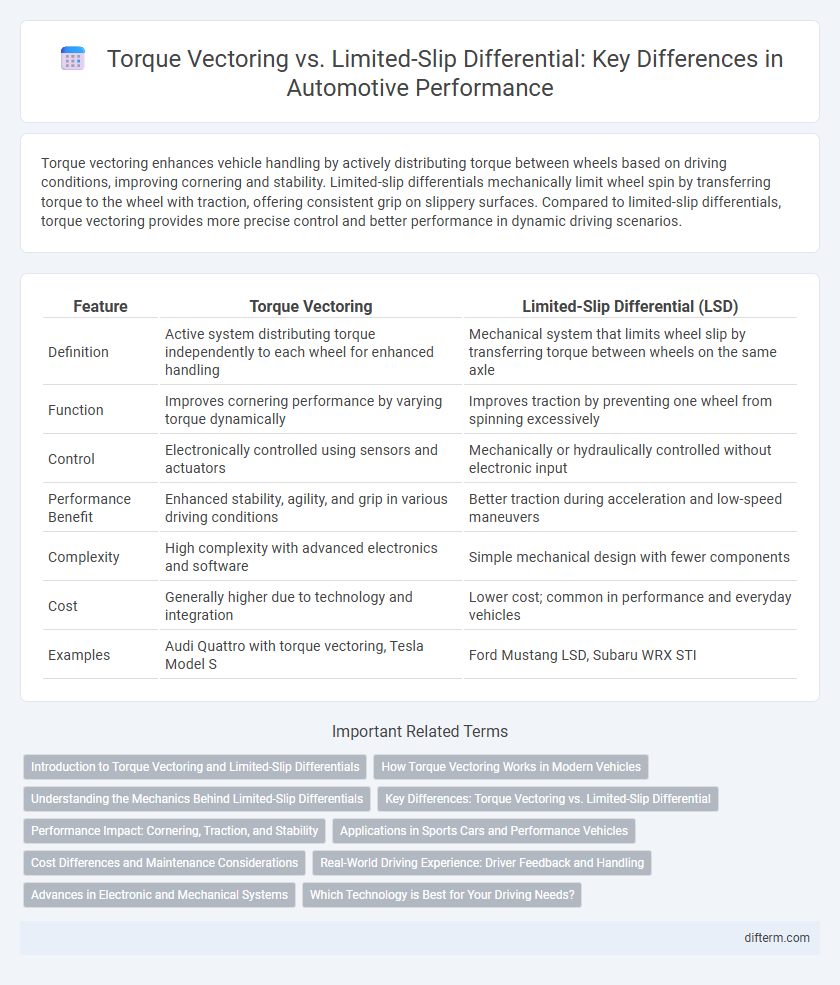

Table of Comparison

| Feature | Torque Vectoring | Limited-Slip Differential (LSD) |

|---|---|---|

| Definition | Active system distributing torque independently to each wheel for enhanced handling | Mechanical system that limits wheel slip by transferring torque between wheels on the same axle |

| Function | Improves cornering performance by varying torque dynamically | Improves traction by preventing one wheel from spinning excessively |

| Control | Electronically controlled using sensors and actuators | Mechanically or hydraulically controlled without electronic input |

| Performance Benefit | Enhanced stability, agility, and grip in various driving conditions | Better traction during acceleration and low-speed maneuvers |

| Complexity | High complexity with advanced electronics and software | Simple mechanical design with fewer components |

| Cost | Generally higher due to technology and integration | Lower cost; common in performance and everyday vehicles |

| Examples | Audi Quattro with torque vectoring, Tesla Model S | Ford Mustang LSD, Subaru WRX STI |

Introduction to Torque Vectoring and Limited-Slip Differentials

Torque vectoring enhances vehicle handling by actively distributing torque between wheels, improving traction and cornering performance beyond traditional systems. Limited-slip differentials mechanically limit wheel spin by transferring torque from a slipping wheel to the one with more grip, providing stability in low-traction conditions. Comparing both, torque vectoring offers more precise control through electronic management, while limited-slip differentials rely on mechanical components for torque distribution.

How Torque Vectoring Works in Modern Vehicles

Torque vectoring in modern vehicles uses advanced sensors and electronic control units to dynamically distribute power between wheels, enhancing traction and cornering stability. This system modulates torque independently to each wheel, allowing for precise handling adjustments based on real-time driving conditions, unlike limited-slip differentials which mechanically split torque based on wheel slip. By actively controlling torque distribution, torque vectoring improves vehicle responsiveness and safety during high-speed maneuvers or adverse road surfaces.

Understanding the Mechanics Behind Limited-Slip Differentials

Limited-slip differentials (LSD) enhance vehicle stability by distributing torque between the driven wheels, preventing excessive wheel slip during cornering or uneven traction conditions. Unlike traditional open differentials, LSDs use clutch packs, gears, or viscous fluids to limit relative wheel speed differences, improving grip and handling performance. Understanding the mechanics behind LSDs reveals how this torque management promotes safer, more controlled driving in dynamic automotive environments.

Key Differences: Torque Vectoring vs. Limited-Slip Differential

Torque vectoring systems actively distribute torque between individual wheels based on driving conditions, enhancing cornering performance and stability by adjusting power dynamically. Limited-slip differentials mechanically limit wheel slip by transferring torque from a spinning wheel to one with more traction, providing improved grip during acceleration but with less precise control than torque vectoring. Torque vectoring offers superior responsiveness and adaptability, making it more effective for high-performance and all-wheel-drive vehicles compared to traditional limited-slip differentials.

Performance Impact: Cornering, Traction, and Stability

Torque vectoring enhances cornering precision by actively distributing torque to individual wheels, improving traction and stability during dynamic driving conditions. Unlike limited-slip differentials, which passively redirect torque based on wheel slip, torque vectoring systems provide real-time adjustments, resulting in superior handling and reduced understeer or oversteer. This advanced control optimizes grip and vehicle stability, especially on challenging road surfaces and high-speed maneuvers, significantly boosting overall performance.

Applications in Sports Cars and Performance Vehicles

Torque vectoring systems enhance handling dynamics in sports cars by distributing torque independently to each wheel, improving cornering agility and stability at high speeds. Limited-slip differentials provide effective power transfer between wheels under varying traction conditions, boosting acceleration and grip during aggressive driving. Performance vehicles leverage torque vectoring for precise control in sharp turns, while limited-slip differentials remain essential for maintaining traction on uneven or slippery surfaces.

Cost Differences and Maintenance Considerations

Torque vectoring systems generally have higher upfront costs due to advanced sensors and electronic controls compared to limited-slip differentials (LSDs), which are mechanically simpler and more affordable. Maintenance of torque vectoring involves specialized diagnostics and potential software updates, increasing long-term service expenses, while LSDs require less frequent attention and use standard mechanical parts. The complexity of torque vectoring systems often leads to higher repair costs and longer service times relative to the more straightforward LSD maintenance procedures.

Real-World Driving Experience: Driver Feedback and Handling

Torque vectoring delivers precise control by independently modulating torque to each wheel, enhancing cornering stability and reducing understeer during real-world driving. Limited-slip differentials improve traction by distributing torque between wheels on the same axle, but may struggle with rapid torque adjustments in dynamic handling scenarios. Drivers often report sharper responsiveness and improved agility with torque vectoring systems, especially in curving roads and adverse conditions, compared to the more mechanical feel of limited-slip differentials.

Advances in Electronic and Mechanical Systems

Advances in electronic torque vectoring systems enable precise distribution of torque to individual wheels, enhancing vehicle stability, traction, and cornering performance beyond the capabilities of traditional mechanical limited-slip differentials (LSDs). Modern torque vectoring integrates sensors, electronic control units, and actuators to dynamically adjust torque in real time, optimizing handling across diverse driving conditions. In contrast, mechanical LSDs rely on fixed or speed-sensitive mechanisms to limit wheel slip, offering less adaptability and slower response compared to advanced electronic vectoring technologies.

Which Technology is Best for Your Driving Needs?

Torque vectoring offers superior handling by actively distributing power to individual wheels based on driving conditions, enhancing cornering and stability. Limited-slip differentials provide a simpler, cost-effective solution that improves traction by limiting wheel slip but lack the precision of torque vectoring systems. Choosing between them depends on your driving style and conditions: torque vectoring is ideal for performance enthusiasts seeking dynamic control, while limited-slip differentials suit everyday drivers needing reliable traction without advanced electronics.

torque vectoring vs limited-slip differential Infographic

difterm.com

difterm.com