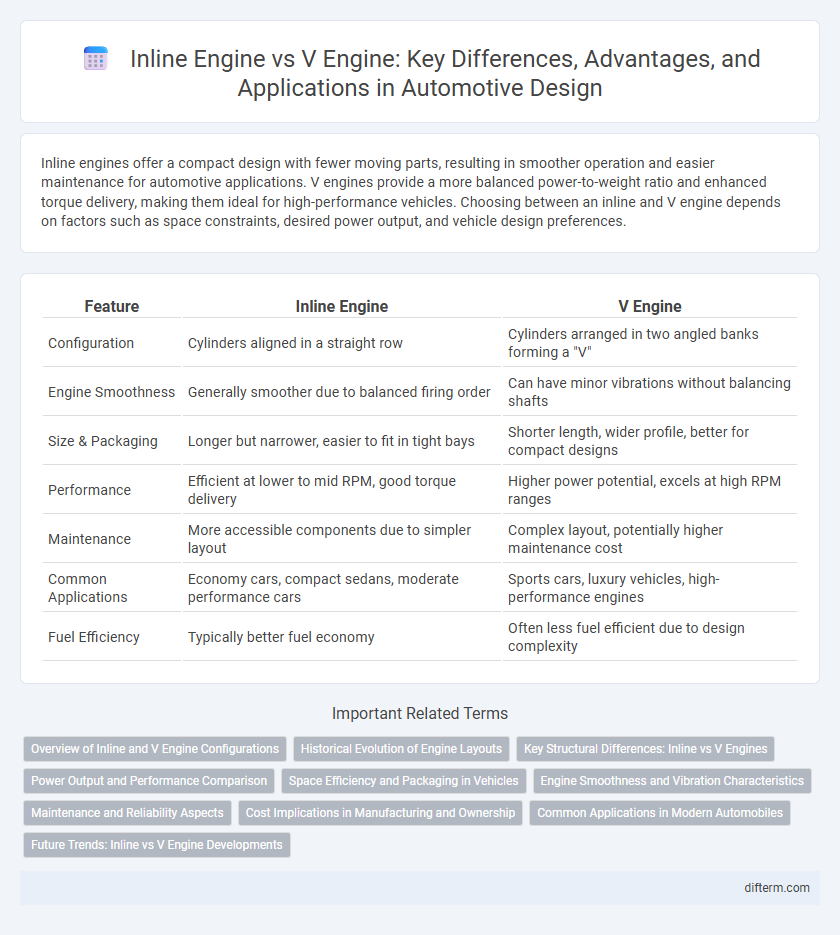

Inline engines offer a compact design with fewer moving parts, resulting in smoother operation and easier maintenance for automotive applications. V engines provide a more balanced power-to-weight ratio and enhanced torque delivery, making them ideal for high-performance vehicles. Choosing between an inline and V engine depends on factors such as space constraints, desired power output, and vehicle design preferences.

Table of Comparison

| Feature | Inline Engine | V Engine |

|---|---|---|

| Configuration | Cylinders aligned in a straight row | Cylinders arranged in two angled banks forming a "V" |

| Engine Smoothness | Generally smoother due to balanced firing order | Can have minor vibrations without balancing shafts |

| Size & Packaging | Longer but narrower, easier to fit in tight bays | Shorter length, wider profile, better for compact designs |

| Performance | Efficient at lower to mid RPM, good torque delivery | Higher power potential, excels at high RPM ranges |

| Maintenance | More accessible components due to simpler layout | Complex layout, potentially higher maintenance cost |

| Common Applications | Economy cars, compact sedans, moderate performance cars | Sports cars, luxury vehicles, high-performance engines |

| Fuel Efficiency | Typically better fuel economy | Often less fuel efficient due to design complexity |

Overview of Inline and V Engine Configurations

Inline engines feature cylinders arranged in a straight line, typically offering a compact design ideal for smaller engine bays and smoother operation due to uniform firing intervals. V engines have cylinders set in two angled banks forming a "V" shape, which allows for a shorter engine length and greater displacement within a confined space, enhancing power output in performance vehicles. The choice between inline and V configurations impacts engine balance, packaging constraints, and vehicle dynamics, influencing overall efficiency and driving experience.

Historical Evolution of Engine Layouts

Inline engines dominated early automotive history due to their simple design and ease of manufacturing, crucial during the mass production era pioneered by Ford. The V engine layout emerged prominently in the mid-20th century, offering enhanced power-to-weight ratios and smoother performance, especially in high-performance and luxury vehicles. Advances in materials and engineering allowed V engines to become more compact and efficient, driving their adoption in diverse automotive applications from muscle cars to modern SUVs.

Key Structural Differences: Inline vs V Engines

Inline engines feature cylinders arranged in a single straight line, offering a compact design that simplifies manufacturing and maintenance. V engines position cylinders in two angled banks, typically 60 to 90 degrees apart, enhancing engine balance and allowing for a shorter engine length. The variation in cylinder layout directly impacts engine packaging, vibration levels, and overall performance characteristics in automotive applications.

Power Output and Performance Comparison

Inline engines typically offer smoother power delivery and better fuel efficiency due to their simpler design and balanced configuration, making them ideal for everyday driving. V engines provide higher power output and torque because of their compact design and ability to accommodate more cylinders, resulting in superior acceleration and performance in high-demand conditions. Performance comparisons reveal that V engines dominate in sports and luxury vehicles, while inline engines are favored in economy and mid-range cars for reliability and cost-effectiveness.

Space Efficiency and Packaging in Vehicles

Inline engines offer superior space efficiency and simpler packaging due to their compact, linear arrangement, allowing easier integration into smaller engine bays and optimizing under-hood space. V engines, with their wider configuration, require more lateral space but provide a lower center of gravity and can accommodate more cylinders within a shorter engine length, which benefits performance-oriented vehicles. Vehicle designers choose inline engines for compact cars where space saving and straightforward packaging are critical, while V engines are favored in larger vehicles requiring higher power output and balanced weight distribution.

Engine Smoothness and Vibration Characteristics

Inline engines generally offer superior smoothness due to their balanced firing order and straightforward crankshaft design, which minimizes engine vibration. V engines, while more compact and powerful, often exhibit increased vibration because of the uneven firing intervals and complex crankshaft geometry. Advanced balancing techniques and engine mounts are employed in V engines to mitigate these inherent vibration challenges and enhance overall smoothness.

Maintenance and Reliability Aspects

Inline engines offer simpler maintenance due to their straightforward design with fewer moving parts, resulting in easier access for routine checks and repairs. V engines, while more compact and powerful, tend to require more intricate maintenance procedures because of their complex architecture and tighter engine compartment fit. Reliability often favors inline engines for long-term durability, especially in applications prioritizing ease of upkeep and consistent performance under varied conditions.

Cost Implications in Manufacturing and Ownership

Inline engines typically have fewer parts and a simpler design, resulting in lower manufacturing costs and easier maintenance compared to V engines. V engines, with their complex architecture and additional components like multiple cylinder banks, generally incur higher production expenses and increased repair costs. Over the vehicle's lifespan, inline engines often deliver better cost efficiency due to reduced maintenance needs and improved fuel economy.

Common Applications in Modern Automobiles

Inline engines are predominantly found in compact cars and economy sedans due to their simpler design and efficient packaging, which allows for better fuel economy and lower production costs. V engines are commonly used in sports cars, luxury vehicles, and large SUVs, offering higher horsepower and smoother performance through their balanced configuration. Modern automakers choose inline engines for their compactness in front-wheel-drive setups, while V engines are favored in rear-wheel-drive platforms requiring greater power output.

Future Trends: Inline vs V Engine Developments

Future developments in automotive engines focus on enhancing efficiency and performance, driving innovation in both inline and V engine configurations. Inline engines are gaining traction for their simpler design and improved fuel economy, while V engines continue to evolve with advanced turbocharging and hybrid integration to maximize power output. Emerging trends indicate a shift towards electrification, with inline engines more frequently paired with electric motors, whereas V engines are optimized for high-performance hybrid drivetrains in luxury and sports vehicles.

Inline engine vs V engine Infographic

difterm.com

difterm.com