The CANbus system offers advanced diagnostic capabilities and streamlined communication between automotive components, outperforming traditional analog wiring in efficiency and reliability. Unlike analog wiring, which relies on numerous separate cables and is prone to interference, CANbus reduces complexity by using a single twisted pair cable for data exchange. This results in faster data transmission, improved fault detection, and enhanced overall vehicle performance.

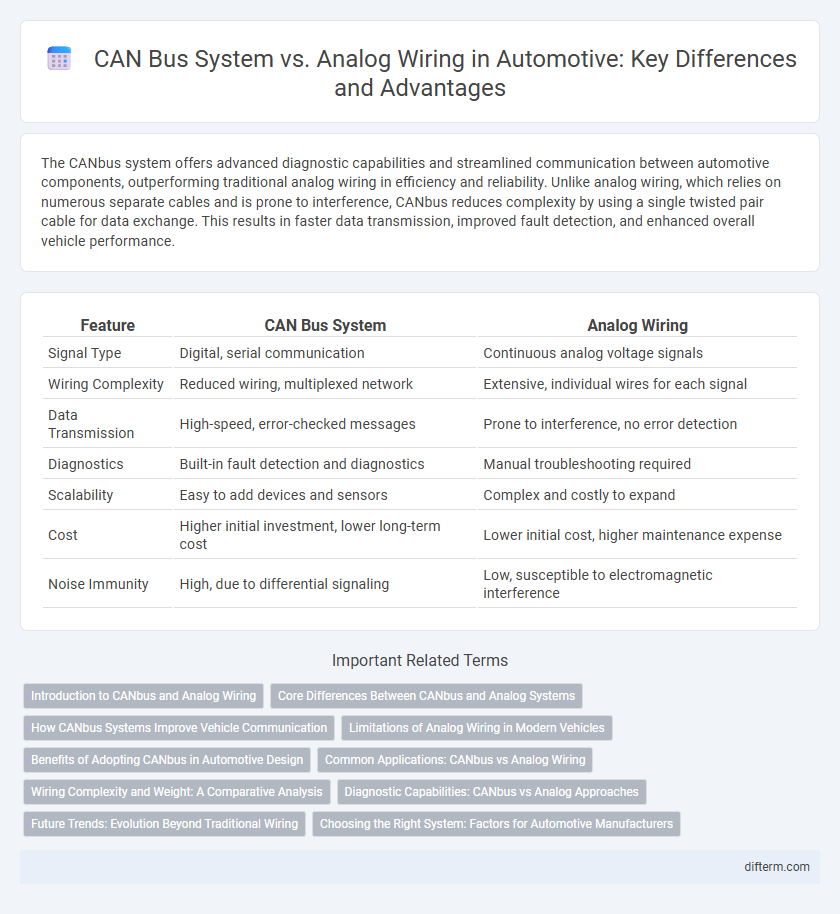

Table of Comparison

| Feature | CAN Bus System | Analog Wiring |

|---|---|---|

| Signal Type | Digital, serial communication | Continuous analog voltage signals |

| Wiring Complexity | Reduced wiring, multiplexed network | Extensive, individual wires for each signal |

| Data Transmission | High-speed, error-checked messages | Prone to interference, no error detection |

| Diagnostics | Built-in fault detection and diagnostics | Manual troubleshooting required |

| Scalability | Easy to add devices and sensors | Complex and costly to expand |

| Cost | Higher initial investment, lower long-term cost | Lower initial cost, higher maintenance expense |

| Noise Immunity | High, due to differential signaling | Low, susceptible to electromagnetic interference |

Introduction to CANbus and Analog Wiring

CANbus system revolutionizes automotive communication by enabling microcontrollers and devices to exchange data without complex analog wiring. Unlike traditional analog wiring that relies on individual wires for each signal, CANbus uses a robust two-wire differential signaling protocol to reduce wiring complexity, improve reliability, and enhance real-time data transmission. This digital communication standard supports fault tolerance and error detection, making it essential for modern vehicle networks.

Core Differences Between CANbus and Analog Systems

CANbus systems utilize a digital communication protocol that allows multiple electronic control units (ECUs) to communicate efficiently over a single twisted-pair cable, reducing wiring complexity and enhancing fault tolerance. In contrast, analog wiring relies on separate individual wires for each signal, which increases the risk of interference and wiring harness weight. CANbus offers higher data integrity and diagnostic capabilities compared to the limited and noise-prone analog signals used in traditional vehicle systems.

How CANbus Systems Improve Vehicle Communication

CANbus systems improve vehicle communication by enabling real-time data exchange between microcontrollers without a host computer, reducing wiring complexity compared to traditional analog wiring. This digital protocol enhances fault detection, diagnostic accuracy, and system scalability, facilitating efficient integration of multiple electronic control units (ECUs). Faster communication speed and error handling in CANbus networks contribute to improved vehicle safety and performance.

Limitations of Analog Wiring in Modern Vehicles

Analog wiring in modern vehicles presents significant limitations, including susceptibility to signal degradation and electromagnetic interference, which can compromise sensor accuracy and overall system reliability. The increased complexity and volume of wiring harnesses also add weight and reduce fuel efficiency, while making diagnostics and modifications more time-consuming and costly. In contrast, CAN bus systems offer centralized communication with enhanced data integrity, simplifying vehicle electronics and improving performance.

Benefits of Adopting CANbus in Automotive Design

CANbus systems in automotive design enhance communication by enabling real-time data exchange between multiple electronic control units, reducing wiring complexity and weight compared to traditional analog wiring. This digital protocol improves diagnostics, fault detection, and system reliability, leading to increased vehicle safety and performance. The streamlined architecture of CANbus also facilitates faster development cycles and easier integration of advanced features such as autonomous driving and vehicle-to-everything (V2X) communication.

Common Applications: CANbus vs Analog Wiring

CANbus systems are widely used in modern automotive applications such as engine control units, anti-lock braking systems, and advanced driver-assistance systems (ADAS) due to their efficient data communication and reduced wiring complexity. Analog wiring remains prevalent in simpler automotive components like basic lighting, traditional sensors, and manual switches where low data transmission and straightforward installation are sufficient. CANbus enables real-time diagnostics and seamless integration of multiple electronic control units (ECUs), whereas analog wiring limits system scalability and diagnostic capabilities.

Wiring Complexity and Weight: A Comparative Analysis

CANbus systems significantly reduce wiring complexity and vehicular weight by utilizing a single twisted-pair cable for multiple data signals, compared to traditional analog wiring, which requires extensive, bulky harnesses with individual wires for each signal. This streamlined communication network not only minimizes potential points of failure but also improves fuel efficiency and vehicle performance due to reduced mass. The efficient wiring architecture of CANbus contributes to easier diagnostics and scalability in modern automotive electronic systems.

Diagnostic Capabilities: CANbus vs Analog Approaches

CANbus systems offer superior diagnostic capabilities compared to analog wiring by providing real-time data communication and standardized fault codes, enabling precise and rapid identification of vehicle issues. Unlike analog wiring, which relies on voltage fluctuations and often requires manual, time-consuming diagnostics, CANbus facilitates integration with onboard diagnostic tools like OBD-II scanners. This advanced communication protocol enhances maintenance efficiency and reduces downtime by streamlining error detection and system monitoring across multiple automotive subsystems.

Future Trends: Evolution Beyond Traditional Wiring

The CANbus system is rapidly transforming automotive electrical architecture by enabling robust, high-speed communication between vehicle components, reducing the complexity and weight associated with traditional analog wiring. Future trends in automotive design emphasize the integration of advanced CANbus protocols, such as CAN FD and CAN XL, to support increasing data demands from autonomous driving and connected vehicle technologies. This evolution beyond traditional wiring promises enhanced diagnostic capabilities, improved system reliability, and greater scalability for next-generation electric and hybrid vehicles.

Choosing the Right System: Factors for Automotive Manufacturers

Automotive manufacturers must evaluate factors such as data transmission speed, wiring complexity, and diagnostic capabilities when choosing between CANbus systems and analog wiring. CANbus offers enhanced communication reliability and scalability, reducing wiring harness size and weight while enabling real-time fault detection. Analog wiring may be preferred for simpler, low-cost applications with limited electronic integration but lacks the flexibility and advanced diagnostics that CANbus provides.

Canbus system vs Analog wiring Infographic

difterm.com

difterm.com