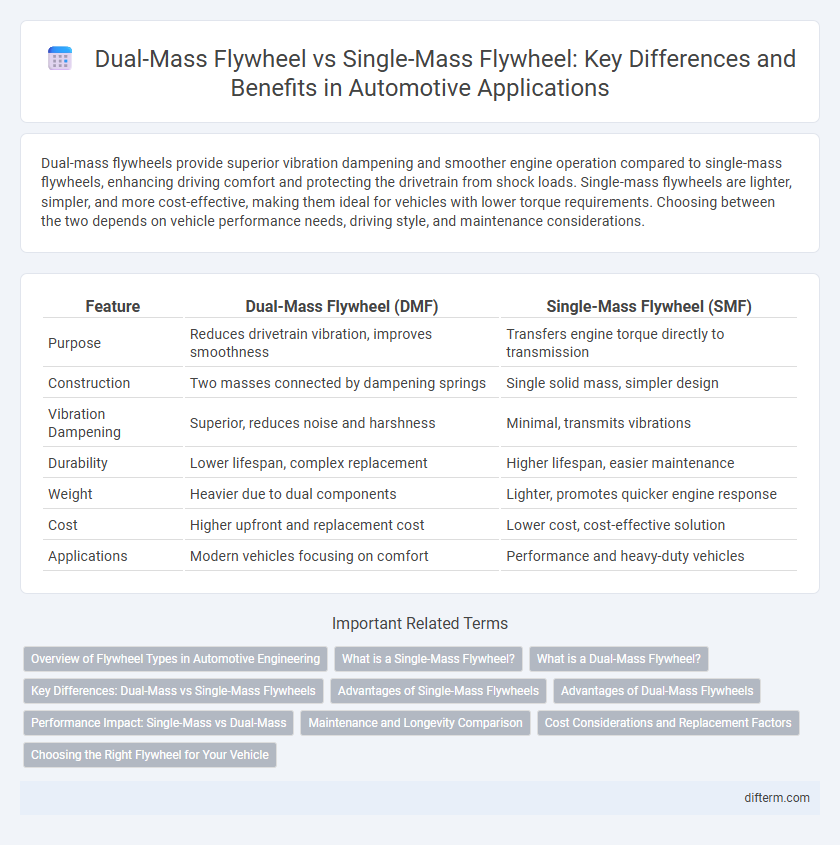

Dual-mass flywheels provide superior vibration dampening and smoother engine operation compared to single-mass flywheels, enhancing driving comfort and protecting the drivetrain from shock loads. Single-mass flywheels are lighter, simpler, and more cost-effective, making them ideal for vehicles with lower torque requirements. Choosing between the two depends on vehicle performance needs, driving style, and maintenance considerations.

Table of Comparison

| Feature | Dual-Mass Flywheel (DMF) | Single-Mass Flywheel (SMF) |

|---|---|---|

| Purpose | Reduces drivetrain vibration, improves smoothness | Transfers engine torque directly to transmission |

| Construction | Two masses connected by dampening springs | Single solid mass, simpler design |

| Vibration Dampening | Superior, reduces noise and harshness | Minimal, transmits vibrations |

| Durability | Lower lifespan, complex replacement | Higher lifespan, easier maintenance |

| Weight | Heavier due to dual components | Lighter, promotes quicker engine response |

| Cost | Higher upfront and replacement cost | Lower cost, cost-effective solution |

| Applications | Modern vehicles focusing on comfort | Performance and heavy-duty vehicles |

Overview of Flywheel Types in Automotive Engineering

Dual-mass flywheels (DMF) incorporate two separate masses connected by a series of springs to dampen engine vibrations and improve driveline smoothness, primarily enhancing comfort in modern vehicles with high torque engines. Single-mass flywheels (SMF) consist of a single solid disc offering durability and simplicity, often preferred in performance and racing applications due to their lighter weight and direct power transfer. The choice between DMF and SMF depends on factors like engine torque characteristics, vehicle application, and desired balance between vibration reduction and mechanical efficiency.

What is a Single-Mass Flywheel?

A single-mass flywheel is a solid, one-piece disc attached to the engine's crankshaft that helps store rotational energy and maintain engine momentum during gear changes. It provides a simpler, more cost-effective design compared to dual-mass flywheels but transfers more vibrations to the drivetrain, which can affect driving comfort. Typically used in older or less powerful vehicles, single-mass flywheels require less maintenance but may lead to increased wear on transmission components.

What is a Dual-Mass Flywheel?

A dual-mass flywheel (DMF) is an advanced automotive component designed to reduce engine vibrations and improve driving comfort by utilizing two separate flywheel masses connected via springs. It absorbs torsional vibrations more effectively than a single-mass flywheel, enhancing drivetrain smoothness and protecting the transmission system from shock loads. Commonly found in modern manual transmissions, the DMF optimizes engine performance and longevity by dampening irregular torque fluctuations generated during combustion.

Key Differences: Dual-Mass vs Single-Mass Flywheels

Dual-mass flywheels feature two separate masses connected by springs, providing enhanced vibration damping and smoother torque transfer in modern vehicles compared to single-mass flywheels, which consist of a single solid unit. The dual-mass design reduces drivetrain noise and wear, improving driving comfort and longevity, while single-mass flywheels offer simplicity, lower cost, and are typically used in older or less powerful engines. Choosing between dual-mass and single-mass flywheels depends on vehicle application, engine characteristics, and desired performance or maintenance requirements.

Advantages of Single-Mass Flywheels

Single-mass flywheels offer advantages such as lower cost, simpler design, and reduced weight compared to dual-mass flywheels, leading to improved fuel efficiency and easier maintenance. They provide more direct power transfer, enhancing engine responsiveness and performance in vehicles with less vibration sensitivity. This makes single-mass flywheels ideal for applications where durability and straightforward operation outweigh the benefits of vibration damping.

Advantages of Dual-Mass Flywheels

Dual-mass flywheels significantly reduce drivetrain vibrations and noise by isolating torsional vibrations between the engine and transmission, enhancing overall driving comfort. They improve clutch lifespan and protect transmission components by absorbing engine torque fluctuations more efficiently than single-mass flywheels. This advanced design leads to smoother gear shifts and better fuel efficiency, making dual-mass flywheels a preferred choice in modern vehicles.

Performance Impact: Single-Mass vs Dual-Mass

Dual-mass flywheels significantly reduce drivetrain vibrations by absorbing engine torque fluctuations, resulting in smoother acceleration and enhanced vehicle comfort compared to single-mass flywheels. Single-mass flywheels, while lighter and more responsive, transmit more engine vibrations and can lead to increased wear on transmission components. Performance-focused vehicles often favor single-mass flywheels for quicker throttle response, whereas dual-mass designs prioritize long-term durability and NVH (Noise, Vibration, and Harshness) reduction.

Maintenance and Longevity Comparison

Dual-mass flywheels require more specialized maintenance due to their complex design and internal damping mechanisms, which can lead to higher repair costs over time. Single-mass flywheels offer greater durability with fewer components, resulting in lower maintenance frequency and extended longevity in typical driving conditions. Vehicles equipped with dual-mass flywheels may experience reduced lifespan if subjected to aggressive driving, whereas single-mass flywheels generally withstand harsh usage with less risk of failure.

Cost Considerations and Replacement Factors

Dual-mass flywheels generally incur higher initial costs and increased replacement expenses due to their complex design and specialized materials. Single-mass flywheels offer a more cost-effective solution with simpler construction, leading to lower repair and maintenance fees. Replacement frequency for dual-mass flywheels tends to be higher, as they are prone to wear from dampening components, influencing long-term ownership costs.

Choosing the Right Flywheel for Your Vehicle

Selecting the right flywheel for your vehicle depends on factors like engine size, driving style, and noise reduction needs. Dual-mass flywheels excel in absorbing engine vibrations and improving ride comfort, making them ideal for modern, turbocharged engines and smooth city driving. Single-mass flywheels offer durability and better performance for high-revving engines, preferred in racing and heavy-duty applications due to their simplicity and cost-effectiveness.

dual-mass flywheel vs single-mass flywheel Infographic

difterm.com

difterm.com