Cast wheels offer a budget-friendly option with intricate designs, while forged wheels provide superior strength and lighter weight due to their manufacturing process. Forged wheels enhance performance and durability, making them ideal for high-performance and off-road vehicles. Cast wheels may be more prone to cracking under extreme conditions but still serve well for everyday driving needs.

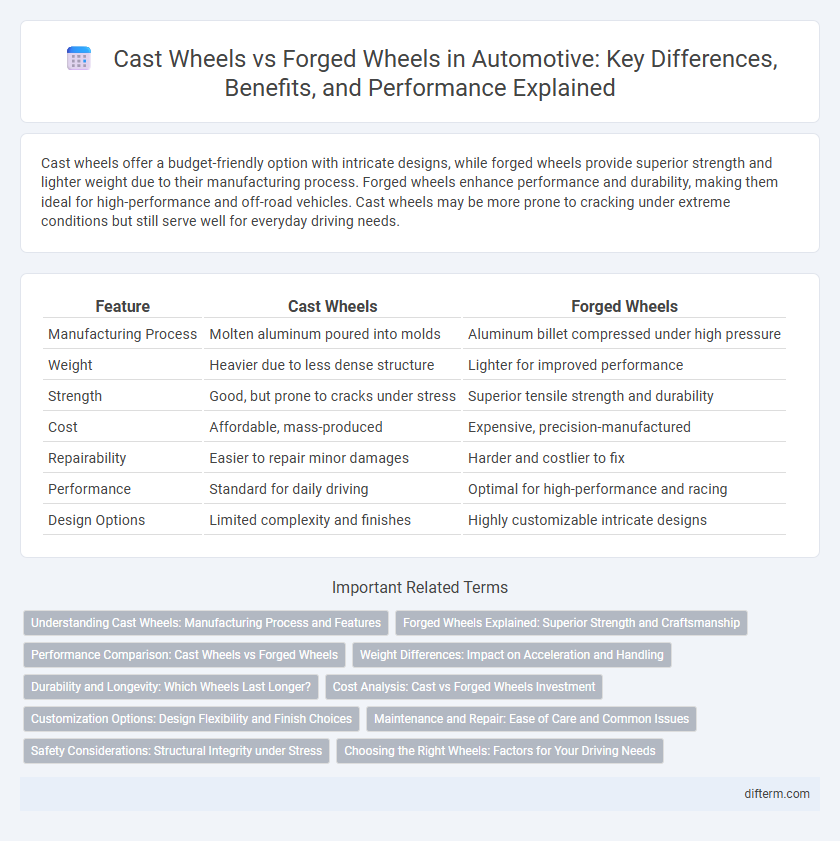

Table of Comparison

| Feature | Cast Wheels | Forged Wheels |

|---|---|---|

| Manufacturing Process | Molten aluminum poured into molds | Aluminum billet compressed under high pressure |

| Weight | Heavier due to less dense structure | Lighter for improved performance |

| Strength | Good, but prone to cracks under stress | Superior tensile strength and durability |

| Cost | Affordable, mass-produced | Expensive, precision-manufactured |

| Repairability | Easier to repair minor damages | Harder and costlier to fix |

| Performance | Standard for daily driving | Optimal for high-performance and racing |

| Design Options | Limited complexity and finishes | Highly customizable intricate designs |

Understanding Cast Wheels: Manufacturing Process and Features

Cast wheels are produced by pouring molten aluminum into molds, allowing intricate designs and cost-effective mass production. This manufacturing process often results in wheels that are heavier and less durable compared to forged wheels, but they provide sufficient strength for everyday driving conditions. The casting method enables high customization in shape and finish, making cast wheels popular for aesthetic diversity and affordability in the automotive industry.

Forged Wheels Explained: Superior Strength and Craftsmanship

Forged wheels are crafted from a solid billet of aluminum, subjected to extreme pressure that aligns the metal's grain structure for enhanced strength and durability. This process results in wheels that are not only lighter but also more resistant to cracks and bends compared to traditional cast wheels, making them ideal for high-performance and luxury vehicles. Their superior craftsmanship allows for precise engineering tolerances, improved heat dissipation, and optimal weight reduction, contributing to better handling and fuel efficiency in automotive applications.

Performance Comparison: Cast Wheels vs Forged Wheels

Forged wheels offer superior performance compared to cast wheels due to their enhanced strength-to-weight ratio, resulting in better acceleration, braking, and handling. The forging process aligns metal grain structure, providing increased durability and resistance to impact, which is crucial for high-performance driving. Cast wheels, while more affordable, tend to be heavier and less rigid, potentially compromising precise steering response and overall vehicle dynamics.

Weight Differences: Impact on Acceleration and Handling

Cast wheels are generally heavier than forged wheels due to their manufacturing process, which affects overall vehicle weight and rotational mass. The reduced weight of forged wheels lowers unsprung mass, enhancing acceleration and improving handling responsiveness by enabling quicker suspension reactions. This weight difference directly contributes to better fuel efficiency and more precise cornering performance in automotive applications.

Durability and Longevity: Which Wheels Last Longer?

Forged wheels offer superior durability and longevity compared to cast wheels due to their manufacturing process, which involves compressing aluminum under high pressure to create a denser, stronger structure. Cast wheels, made by pouring molten aluminum into molds, are more prone to cracking and bending under stress, reducing their lifespan. High-performance and off-road vehicles benefit from forged wheels' enhanced resistance to impact and wear, ensuring longer-lasting performance and safety.

Cost Analysis: Cast vs Forged Wheels Investment

Cast wheels are generally more affordable due to lower manufacturing costs and widespread production, making them a budget-friendly choice for most vehicles. Forged wheels involve a more complex process that increases material strength and reduces weight but significantly raises the initial investment. Over time, the durability and performance benefits of forged wheels can justify the higher upfront cost, especially for high-performance or luxury automotive applications.

Customization Options: Design Flexibility and Finish Choices

Cast wheels provide extensive customization options due to their manufacturing process, allowing intricate designs and a variety of complex shapes to be produced with ease. Forged wheels, while generally limited in design complexity compared to cast wheels, offer superior finish quality and durability that enhances the overall aesthetic appeal and longevity. Both cast and forged wheels support diverse finish choices, including polished, painted, and machined surfaces, catering to tailored style preferences in the automotive aftermarket.

Maintenance and Repair: Ease of Care and Common Issues

Cast wheels require less frequent maintenance due to their durable, one-piece construction but are more prone to cracking under impact, making repairs challenging and often necessitating full replacement. Forged wheels boast superior strength and resistance to bending, allowing for easier repairs from minor damage like bends or scratches, which can often be corrected without replacing the entire wheel. Routine inspection and cleaning extend the lifespan of both types, with forged wheels generally demanding more specialized care due to their complex manufacturing process.

Safety Considerations: Structural Integrity under Stress

Cast wheels generally exhibit lower structural integrity under stress due to potential micro-porosity and inconsistencies formed during the casting process, increasing the risk of cracks and failure. Forged wheels, manufactured through a high-pressure forging process, demonstrate superior strength and durability by aligning metal grains, which enhances resistance to impacts and high-load conditions crucial for automotive safety. Selecting forged wheels improves vehicle safety by providing enhanced load-bearing capacity, reducing the likelihood of sudden wheel failure during demanding driving scenarios.

Choosing the Right Wheels: Factors for Your Driving Needs

Cast wheels offer affordability and complex designs, making them suitable for everyday driving and moderate performance needs, while forged wheels provide superior strength, reduced weight, and enhanced durability, ideal for high-performance and motorsport applications. Consider key factors such as driving style, vehicle type, and budget when selecting between cast and forged wheels to optimize handling, fuel efficiency, and safety. Weight differences significantly affect acceleration and braking, with forged wheels typically improving overall vehicle dynamics due to their precise manufacturing process.

cast wheels vs forged wheels Infographic

difterm.com

difterm.com