Drive-by-wire systems replace traditional cable throttle controls with electronic sensors and actuators, offering precise throttle management and faster response times. These systems enhance fuel efficiency and reduce mechanical wear, making them a popular choice in modern vehicles. Cable throttle mechanisms rely on direct physical connections, which can be less responsive and require more maintenance compared to advanced drive-by-wire technology.

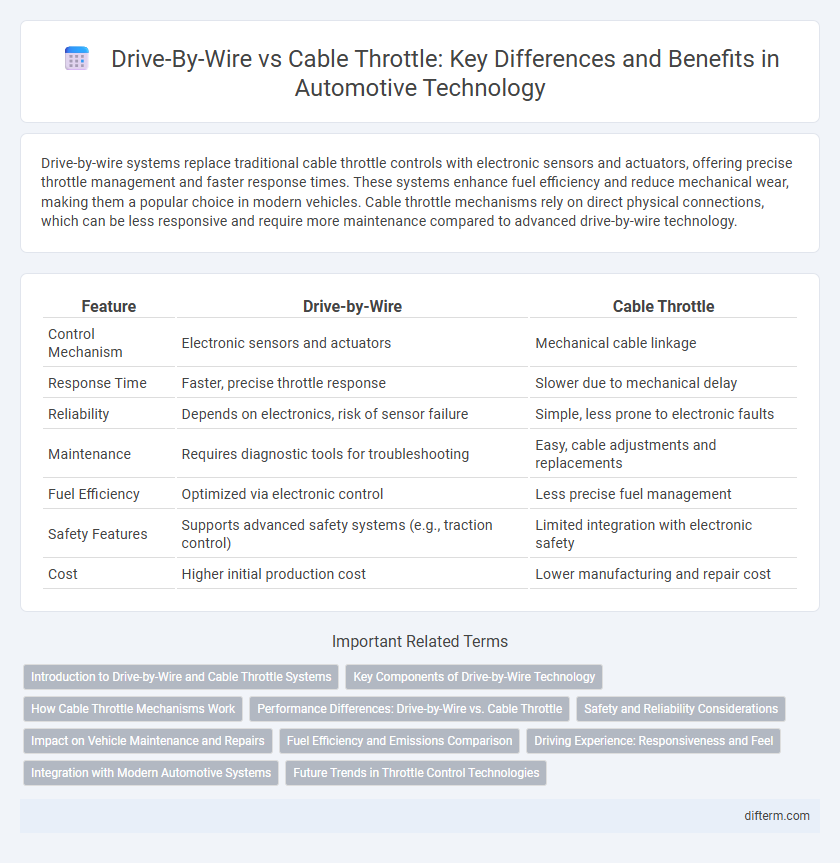

Table of Comparison

| Feature | Drive-by-Wire | Cable Throttle |

|---|---|---|

| Control Mechanism | Electronic sensors and actuators | Mechanical cable linkage |

| Response Time | Faster, precise throttle response | Slower due to mechanical delay |

| Reliability | Depends on electronics, risk of sensor failure | Simple, less prone to electronic faults |

| Maintenance | Requires diagnostic tools for troubleshooting | Easy, cable adjustments and replacements |

| Fuel Efficiency | Optimized via electronic control | Less precise fuel management |

| Safety Features | Supports advanced safety systems (e.g., traction control) | Limited integration with electronic safety |

| Cost | Higher initial production cost | Lower manufacturing and repair cost |

Introduction to Drive-by-Wire and Cable Throttle Systems

Drive-by-wire systems replace traditional mechanical cable throttles with electronic sensors and actuators, enabling precise throttle control and improved fuel efficiency. Cable throttle systems rely on physical cables to connect the accelerator pedal to the throttle valve, offering simplicity and direct feedback. Modern drive-by-wire technology enhances vehicle responsiveness and allows integration with advanced driver-assistance systems (ADAS), transforming automotive performance and safety.

Key Components of Drive-by-Wire Technology

Drive-by-wire technology replaces traditional mechanical cable throttles with electronic control systems, enhancing vehicle responsiveness and precision. Key components include sensors that monitor pedal position, an electronic control unit (ECU) that processes input signals, and actuators that adjust the throttle valve accordingly. This setup enables smoother acceleration, improved fuel efficiency, and integration with advanced driver-assistance systems.

How Cable Throttle Mechanisms Work

Cable throttle mechanisms operate by physically linking the accelerator pedal to the throttle valve through a steel cable, translating the driver's foot pressure directly into throttle movement. This mechanical connection ensures immediate feedback and a tactile feel, allowing precise control over engine power output. The simplicity and reliability of cable throttles make them a longstanding choice in automotive design despite the growing adoption of electronic drive-by-wire systems.

Performance Differences: Drive-by-Wire vs. Cable Throttle

Drive-by-wire systems offer more precise throttle control and faster response times compared to traditional cable throttles, enhancing acceleration and fuel efficiency in modern vehicles. Electronic sensors and actuators in drive-by-wire setups enable adaptive performance tuning and integration with stability control systems, which cable throttles cannot provide due to mechanical limitations. The absence of physical cables reduces wear and maintenance needs, improving long-term reliability and driving consistency in automotive applications.

Safety and Reliability Considerations

Drive-by-wire systems enhance safety by eliminating mechanical linkages prone to wear, providing precise throttle control through electronic signals and enabling advanced features like adaptive cruise control and traction management. Cable throttle mechanisms offer mechanical simplicity and robust reliability but are susceptible to cable stretch or breakage, which can lead to throttle sticking or failure. Automotive manufacturers increasingly favor drive-by-wire technology for its superior fault diagnosis, redundancy options, and integration with vehicle stability systems, significantly improving overall reliability and passenger safety.

Impact on Vehicle Maintenance and Repairs

Drive-by-wire systems reduce mechanical wear by replacing cables with electronic sensors and actuators, leading to fewer throttle-related maintenance issues compared to cable throttles. Repairing drive-by-wire components often requires specialized diagnostic tools and software updates, increasing repair costs and technical complexity. Conversely, cable throttles offer simpler, more accessible repairs but demand regular adjustments and replacements due to cable wear and potential binding.

Fuel Efficiency and Emissions Comparison

Drive-by-wire throttle systems optimize fuel efficiency by precisely controlling air intake through electronic sensors and actuators, reducing fuel consumption compared to traditional cable throttles that rely on mechanical linkages with potential lag. This enhanced control lowers emissions by improving combustion accuracy and enabling advanced engine management strategies such as variable valve timing and adaptive fuel injection. Consequently, drive-by-wire technology supports stricter emission standards and contributes to more environmentally sustainable automotive performance.

Driving Experience: Responsiveness and Feel

Drive-by-wire throttle systems provide enhanced responsiveness through electronic sensors that allow precise throttle control, resulting in smoother acceleration and consistent performance. In contrast, cable throttle mechanisms offer a direct physical connection, delivering a tactile feel that some drivers prefer for its immediacy and feedback. The choice between these systems impacts driving experience, where drive-by-wire emphasizes efficiency and adaptability, while cable throttles prioritize mechanical simplicity and direct driver engagement.

Integration with Modern Automotive Systems

Drive-by-wire throttle systems offer seamless integration with modern automotive technologies such as advanced driver-assistance systems (ADAS), electronic stability control, and adaptive cruise control, enabling precise electronic control and real-time data communication. Unlike cable throttle systems, which rely on mechanical linkages, drive-by-wire eliminates physical constraints, facilitating better compatibility with vehicle network architectures like CAN and Ethernet. The ability of drive-by-wire to interface directly with vehicle control units enhances responsiveness, fuel efficiency, and safety features in contemporary automotive designs.

Future Trends in Throttle Control Technologies

Drive-by-wire throttle systems are increasingly replacing traditional cable throttles due to their enhanced precision, reduced mechanical complexity, and seamless integration with advanced driver-assistance systems (ADAS). Emerging trends emphasize the incorporation of artificial intelligence and sensor fusion to optimize throttle response, improve fuel efficiency, and enable more sophisticated vehicle-to-everything (V2X) communications. The shift towards electric and autonomous vehicles further accelerates the adoption of drive-by-wire technologies as a foundation for intelligent throttle control.

drive-by-wire vs cable throttle Infographic

difterm.com

difterm.com