FPGA offers flexibility with its reprogrammable logic, making it ideal for prototyping and applications requiring rapid iteration, while ASIC provides high performance and energy efficiency through custom-designed circuits optimized for specific tasks. FPGA excels in reducing time-to-market and supports hardware adaptability, whereas ASIC delivers superior speed and lower power consumption in mass production. Choosing between FPGA and ASIC depends on factors such as development cost, volume requirements, and performance needs in technology-driven pet devices.

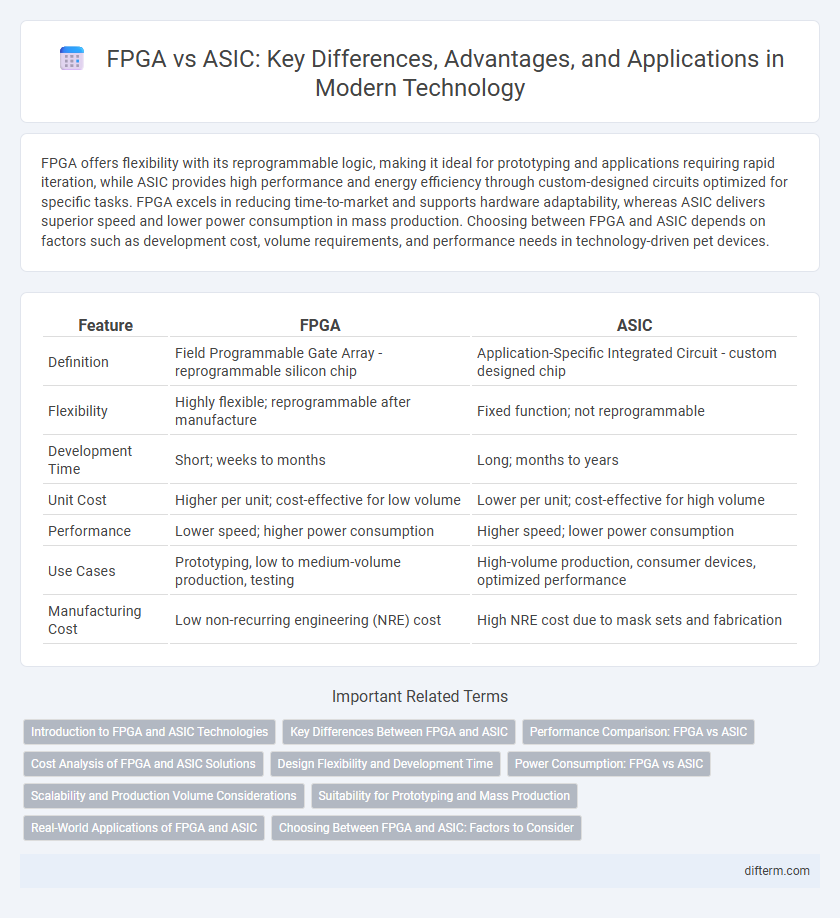

Table of Comparison

| Feature | FPGA | ASIC |

|---|---|---|

| Definition | Field Programmable Gate Array - reprogrammable silicon chip | Application-Specific Integrated Circuit - custom designed chip |

| Flexibility | Highly flexible; reprogrammable after manufacture | Fixed function; not reprogrammable |

| Development Time | Short; weeks to months | Long; months to years |

| Unit Cost | Higher per unit; cost-effective for low volume | Lower per unit; cost-effective for high volume |

| Performance | Lower speed; higher power consumption | Higher speed; lower power consumption |

| Use Cases | Prototyping, low to medium-volume production, testing | High-volume production, consumer devices, optimized performance |

| Manufacturing Cost | Low non-recurring engineering (NRE) cost | High NRE cost due to mask sets and fabrication |

Introduction to FPGA and ASIC Technologies

Field-Programmable Gate Arrays (FPGAs) are integrated circuits designed to be configured by customers or designers after manufacturing, providing flexibility in hardware programming through reconfigurable logic blocks and interconnects. Application-Specific Integrated Circuits (ASICs) are custom-designed chips optimized for specific applications, offering higher performance and lower power consumption at the cost of fixed functionality and longer development times. Both FPGA and ASIC technologies play crucial roles in modern electronics, with FPGAs enabling rapid prototyping and adaptability, while ASICs deliver efficient, high-volume production solutions.

Key Differences Between FPGA and ASIC

FPGA (Field-Programmable Gate Array) offers reconfigurability and faster prototyping, enabling multiple iterations of design changes without manufacturing new hardware. ASIC (Application-Specific Integrated Circuit) provides superior performance, lower power consumption, and cost efficiency for high-volume production due to its customized architecture. Key differences include flexibility in FPGA versus fixed functionality in ASIC, time-to-market speed favoring FPGAs, and unit cost advantages for ASICs in large-scale deployments.

Performance Comparison: FPGA vs ASIC

ASICs deliver superior performance compared to FPGAs by offering higher operating frequencies and lower latency due to their custom-designed silicon architecture. FPGAs provide more flexibility and shorter development cycles but typically consume more power and have lower throughput than ASICs. For applications demanding maximum speed and efficiency, ASICs are the preferred choice, while FPGAs excel in prototyping and adaptable deployments.

Cost Analysis of FPGA and ASIC Solutions

FPGA solutions typically have lower initial development costs due to their reprogrammable nature, making them ideal for prototyping and low to medium volume production runs. ASICs involve high upfront design and fabrication expenses but offer significantly lower per-unit costs at large-scale production, benefiting mass-market applications. Cost efficiency depends on production volume, with FPGAs favored for flexibility and short time-to-market, while ASICs deliver optimized performance and lower long-term expenses in high-volume deployments.

Design Flexibility and Development Time

FPGA offers superior design flexibility due to its reprogrammable architecture, enabling rapid prototyping and iterative development. ASICs require longer development time because of custom design and fabrication processes but deliver optimized performance and lower unit costs for high-volume production. Choosing FPGA accelerates time-to-market, while ASIC suits mass production with fixed design requirements.

Power Consumption: FPGA vs ASIC

ASICs demonstrate markedly lower power consumption compared to FPGAs due to their tailored hardware design optimized for specific tasks. FPGAs consume more power as their reconfigurable logic fabric and routing resources introduce higher static and dynamic power overhead. In power-sensitive applications such as mobile devices and wearables, ASICs offer superior energy efficiency essential for prolonged battery life.

Scalability and Production Volume Considerations

FPGA offers high scalability due to its reconfigurable architecture, making it ideal for prototyping and low to medium production volumes. ASICs provide superior efficiency and lower unit costs at high production volumes but lack the flexibility of FPGAs. The choice between FPGA and ASIC depends on project scale, with FPGA preferred for small-scale, adaptable designs and ASIC for mass production and optimized performance.

Suitability for Prototyping and Mass Production

FPGAs offer rapid reconfigurability, making them ideal for prototyping complex digital circuits and iterative design testing. ASICs, while requiring higher upfront design costs and longer development cycles, provide superior performance and energy efficiency for large-scale mass production. The choice between FPGA and ASIC pivots on production volume and flexibility requirements, with FPGAs excelling in early-stage development and ASICs dominating high-volume deployment.

Real-World Applications of FPGA and ASIC

FPGAs excel in real-world applications requiring rapid prototyping and flexible hardware design, such as aerospace systems, telecommunications, and defense equipment, where adaptability to changing standards is crucial. ASICs dominate in mass-produced consumer electronics like smartphones, automotive control units, and data center accelerators due to their optimized performance, lower unit cost, and power efficiency. Both technologies serve critical roles in AI hardware, with FPGAs enabling customizable neural network implementations and ASICs powering high-throughput inference chips.

Choosing Between FPGA and ASIC: Factors to Consider

Choosing between FPGA and ASIC depends on factors such as development cost, time-to-market, and production volume. FPGAs offer flexibility and rapid prototyping with lower initial costs, ideal for small to medium production runs or evolving designs. ASICs provide higher performance, lower unit cost, and optimized power efficiency, making them suitable for high-volume, fixed-function applications.

FPGA vs ASIC Infographic

difterm.com

difterm.com