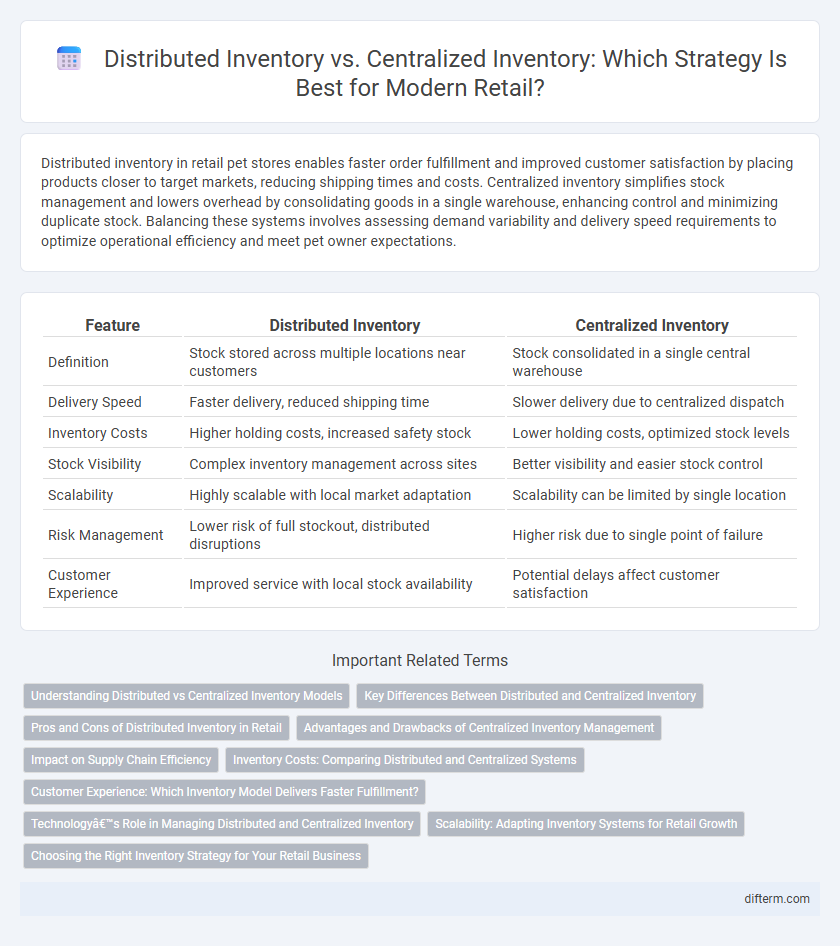

Distributed inventory in retail pet stores enables faster order fulfillment and improved customer satisfaction by placing products closer to target markets, reducing shipping times and costs. Centralized inventory simplifies stock management and lowers overhead by consolidating goods in a single warehouse, enhancing control and minimizing duplicate stock. Balancing these systems involves assessing demand variability and delivery speed requirements to optimize operational efficiency and meet pet owner expectations.

Table of Comparison

| Feature | Distributed Inventory | Centralized Inventory |

|---|---|---|

| Definition | Stock stored across multiple locations near customers | Stock consolidated in a single central warehouse |

| Delivery Speed | Faster delivery, reduced shipping time | Slower delivery due to centralized dispatch |

| Inventory Costs | Higher holding costs, increased safety stock | Lower holding costs, optimized stock levels |

| Stock Visibility | Complex inventory management across sites | Better visibility and easier stock control |

| Scalability | Highly scalable with local market adaptation | Scalability can be limited by single location |

| Risk Management | Lower risk of full stockout, distributed disruptions | Higher risk due to single point of failure |

| Customer Experience | Improved service with local stock availability | Potential delays affect customer satisfaction |

Understanding Distributed vs Centralized Inventory Models

Distributed inventory models allocate stock across multiple regional warehouses or retail locations, enabling faster delivery and improved customer service by reducing shipping distances. Centralized inventory consolidates all stock in a single location, streamlining inventory management and lowering storage costs but potentially increasing lead times for customers. Retailers must balance inventory holding costs, transportation expenses, and service levels when choosing between distributed and centralized inventory systems.

Key Differences Between Distributed and Centralized Inventory

Distributed inventory spreads stock across multiple locations near customers, enhancing delivery speed and local demand responsiveness, while centralized inventory concentrates all products in a single warehouse, optimizing inventory management and reducing holding costs. Distributed systems increase complexity in coordination and higher transportation expenses but improve customer satisfaction through faster fulfillment. Centralized inventory benefits from economies of scale and simplified control but may face longer delivery times and higher risk of stockouts in distant markets.

Pros and Cons of Distributed Inventory in Retail

Distributed inventory in retail enhances product availability by positioning stock closer to customers, significantly reducing delivery times and improving service levels. However, it increases operational complexity and costs due to multiple storage locations requiring inventory management, security, and coordination efforts. While it boosts flexibility and resilience against supply chain disruptions, it can lead to higher overall inventory holding costs compared to centralized inventory models.

Advantages and Drawbacks of Centralized Inventory Management

Centralized inventory management streamlines stock control by consolidating products in a single location, reducing storage costs and simplifying order fulfillment processes. However, it increases the risk of stockouts and longer delivery times in distant markets, potentially impacting customer satisfaction. This approach requires robust demand forecasting and efficient logistics to minimize disruptions and maintain optimal inventory levels.

Impact on Supply Chain Efficiency

Distributed inventory enhances supply chain efficiency by reducing transportation time and costs through geographically dispersed stock locations, enabling faster response to local demand fluctuations. Centralized inventory consolidates stock in a single location, which simplifies inventory management and can lower holding costs but risks longer lead times and potential supply disruptions. Efficient supply chain operations balance these models by leveraging distributed inventory for agility while maintaining centralized hubs for economies of scale.

Inventory Costs: Comparing Distributed and Centralized Systems

Distributed inventory systems generally incur higher carrying costs due to the need to maintain stock at multiple locations, increasing expenses related to storage, insurance, and labor. Centralized inventory minimizes holding costs by consolidating stock in a single warehouse, enabling bulk purchasing and streamlined management yet potentially raising transportation expenses and risking stockouts in distant markets. Balancing these cost factors depends on factors like order volume, delivery speed requirements, and geographic reach, influencing a retailer's choice between distributed versus centralized inventory models.

Customer Experience: Which Inventory Model Delivers Faster Fulfillment?

Distributed inventory models enhance customer experience by reducing shipping distances and enabling faster order fulfillment through multiple localized warehouses. Centralized inventory systems often face longer delivery times due to single-location stock, which can delay order processing and shipping. Retailers adopting distributed inventory frameworks benefit from improved order accuracy and quicker response to demand fluctuations, directly boosting customer satisfaction.

Technology’s Role in Managing Distributed and Centralized Inventory

Advanced inventory management software utilizes real-time data analytics and IoT integration to optimize both distributed and centralized inventory systems, enhancing accuracy and responsiveness. Cloud-based platforms enable seamless synchronization across multiple locations, improving demand forecasting and reducing stockouts in distributed inventory models. Centralized inventory benefits from AI-driven automation tools that streamline replenishment processes and lower operational costs through efficient resource allocation.

Scalability: Adapting Inventory Systems for Retail Growth

Distributed inventory systems enhance scalability by enabling retailers to allocate stock across multiple locations, reducing delivery times and optimizing local demand fulfillment. Centralized inventory consolidates stock in a single warehouse, simplifying management but potentially limiting responsiveness as retail operations expand. For rapid retail growth, distributed inventory offers better flexibility to scale with market demand and geographic reach.

Choosing the Right Inventory Strategy for Your Retail Business

Distributed inventory enhances product availability by placing stock closer to customers, reducing delivery times and improving customer satisfaction. Centralized inventory consolidates stock in a single location, optimizing inventory control and reducing operational costs through economies of scale. Selecting the right inventory strategy depends on factors such as order volume, geographic customer distribution, and supply chain efficiency, ensuring alignment with business goals and customer expectations.

Distributed Inventory vs Centralized Inventory Infographic

difterm.com

difterm.com