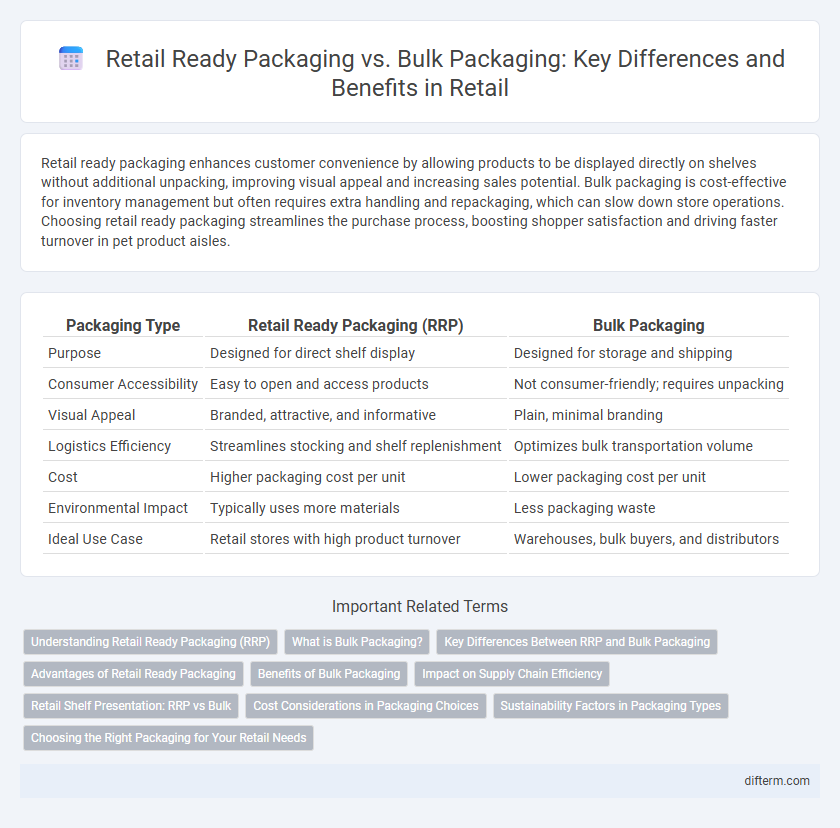

Retail ready packaging enhances customer convenience by allowing products to be displayed directly on shelves without additional unpacking, improving visual appeal and increasing sales potential. Bulk packaging is cost-effective for inventory management but often requires extra handling and repackaging, which can slow down store operations. Choosing retail ready packaging streamlines the purchase process, boosting shopper satisfaction and driving faster turnover in pet product aisles.

Table of Comparison

| Packaging Type | Retail Ready Packaging (RRP) | Bulk Packaging |

|---|---|---|

| Purpose | Designed for direct shelf display | Designed for storage and shipping |

| Consumer Accessibility | Easy to open and access products | Not consumer-friendly; requires unpacking |

| Visual Appeal | Branded, attractive, and informative | Plain, minimal branding |

| Logistics Efficiency | Streamlines stocking and shelf replenishment | Optimizes bulk transportation volume |

| Cost | Higher packaging cost per unit | Lower packaging cost per unit |

| Environmental Impact | Typically uses more materials | Less packaging waste |

| Ideal Use Case | Retail stores with high product turnover | Warehouses, bulk buyers, and distributors |

Understanding Retail Ready Packaging (RRP)

Retail Ready Packaging (RRP) enhances product visibility and simplifies shelf stocking by delivering merchandise in pre-designed, easy-to-display units that reduce labor costs and improve inventory management. Unlike bulk packaging, which typically requires extensive unpacking and arrangement, RRP is engineered to seamlessly integrate with retail shelving, boosting consumer engagement and sales conversion rates. Its use of branded graphics and structural design contributes to a stronger in-store presence and streamlines the supply chain from warehouse to point of sale.

What is Bulk Packaging?

Bulk packaging involves grouping large quantities of products in a single container or package without individual retail presentation, designed primarily for transportation and storage efficiency. It reduces packaging material costs and optimizes space during shipping, but often requires additional handling for individual product display at retail locations. This type of packaging is common in wholesale distribution and supply chains where products are later repackaged or merchandised.

Key Differences Between RRP and Bulk Packaging

Retail Ready Packaging (RRP) is designed to be both the shipping and display unit, allowing products to be quickly placed on shelves without unpacking; it enhances shelf appeal and streamlines stocking processes. Bulk packaging, in contrast, prioritizes maximizing product quantity per container for cost-efficient shipping but requires additional unpacking and merchandising at the retail location. The key differences involve convenience and presentation with RRP, versus cost-efficiency and volume with bulk packaging solutions.

Advantages of Retail Ready Packaging

Retail ready packaging improves product visibility and enhances shelf appeal, driving higher consumer engagement and increased sales. Designed for quick stocking and easy access, it reduces labor costs and minimizes out-of-stock situations. This packaging optimizes shelf space, supports sustainable practices through reduced waste, and strengthens brand recognition in competitive retail environments.

Benefits of Bulk Packaging

Bulk packaging reduces overall packaging costs by minimizing materials and labor required per unit, making it ideal for large-volume shipments. It enhances supply chain efficiency through easier handling, storage, and transportation due to its compact nature. Lower environmental impact results from decreased packaging waste, supporting sustainability initiatives in retail operations.

Impact on Supply Chain Efficiency

Retail ready packaging (RRP) streamlines the supply chain by enabling faster shelf stocking and reducing handling time compared to bulk packaging. RRP minimizes storage space and lowers transportation costs through optimized carton sizes and modular designs. Enhanced visibility and easier inventory management from RRP further improve overall supply chain efficiency and responsiveness.

Retail Shelf Presentation: RRP vs Bulk

Retail Ready Packaging (RRP) enhances shelf presentation by allowing products to be displayed directly on shelves without repacking, improving visual appeal and ease of access. Bulk packaging requires manual unpacking and arranging, often leading to inconsistent presentation and increased labor costs. Effective RRP design boosts product visibility, encourages impulse buying, and streamlines stock replenishment in retail environments.

Cost Considerations in Packaging Choices

Retail ready packaging typically incurs higher upfront costs due to customized design, branding, and smaller production runs, but reduces labor and shelf stocking expenses by simplifying product display. Bulk packaging offers lower per-unit packaging costs and is ideal for high-volume shipments, though it often requires additional handling, repackaging, and labor at the retail location, increasing overall operational expenses. Evaluating total cost of ownership--including packaging, transportation, labor, and shelf replenishment--is critical for optimizing profit margins in retail supply chains.

Sustainability Factors in Packaging Types

Retail ready packaging (RRP) significantly reduces packaging waste by eliminating the need for secondary packaging, enhancing sustainability through efficient material usage and lower transportation emissions. In contrast, bulk packaging often involves larger quantities and heavier materials, which can increase carbon footprint but may reduce per-unit packaging waste. Choosing RRP supports circular economy goals by enabling easier recycling and minimizing landfill contributions compared to traditional bulk packaging solutions.

Choosing the Right Packaging for Your Retail Needs

Retail ready packaging enhances product visibility and accelerates shelf stocking by allowing immediate placement on store shelves, whereas bulk packaging optimizes shipping efficiency and reduces handling costs for large quantities. Selecting the right packaging depends on factors such as retail environment, product type, shelf life, and customer engagement goals. Prioritizing retail ready packaging can boost impulse purchases and streamline inventory management in fast-paced retail settings.

retail ready packaging vs bulk packaging Infographic

difterm.com

difterm.com