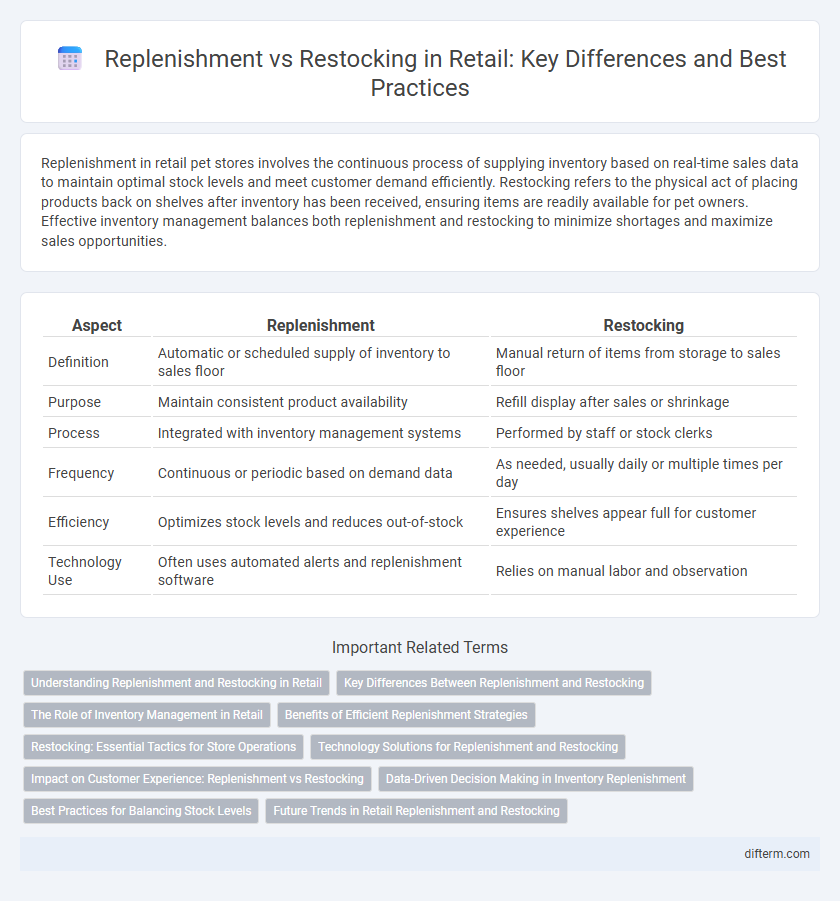

Replenishment in retail pet stores involves the continuous process of supplying inventory based on real-time sales data to maintain optimal stock levels and meet customer demand efficiently. Restocking refers to the physical act of placing products back on shelves after inventory has been received, ensuring items are readily available for pet owners. Effective inventory management balances both replenishment and restocking to minimize shortages and maximize sales opportunities.

Table of Comparison

| Aspect | Replenishment | Restocking |

|---|---|---|

| Definition | Automatic or scheduled supply of inventory to sales floor | Manual return of items from storage to sales floor |

| Purpose | Maintain consistent product availability | Refill display after sales or shrinkage |

| Process | Integrated with inventory management systems | Performed by staff or stock clerks |

| Frequency | Continuous or periodic based on demand data | As needed, usually daily or multiple times per day |

| Efficiency | Optimizes stock levels and reduces out-of-stock | Ensures shelves appear full for customer experience |

| Technology Use | Often uses automated alerts and replenishment software | Relies on manual labor and observation |

Understanding Replenishment and Restocking in Retail

Replenishment in retail refers to the process of automatically refilling inventory based on real-time sales data and predictive analytics to maintain optimal stock levels, ensuring continuous product availability. Restocking involves physically placing sold items back onto shelves, often as a manual or scheduled task performed by staff. Efficient replenishment systems reduce stockouts and excess inventory, while restocking ensures the store shelves are consistently organized and ready for customers.

Key Differences Between Replenishment and Restocking

Replenishment in retail involves proactively forecasting demand and ordering inventory before stock levels run low, ensuring continuous product availability. Restocking refers to the process of physically placing received goods onto shelves or storage areas after inventory has been replenished or sold. Key differences include replenishment's focus on inventory planning and supply chain coordination, while restocking centers on operational execution within the store environment.

The Role of Inventory Management in Retail

Inventory management in retail plays a crucial role in distinguishing replenishment from restocking, where replenishment involves the proactive forecasting and ordering of stock to maintain optimal inventory levels, while restocking is the physical process of placing products on shelves. Effective inventory management systems utilize real-time data analytics and demand forecasting to ensure timely replenishment, minimizing stockouts and excess inventory. This strategic approach enhances customer satisfaction and operational efficiency by aligning supply with consumer demand patterns.

Benefits of Efficient Replenishment Strategies

Efficient replenishment strategies in retail minimize stockouts and reduce excess inventory, leading to improved customer satisfaction and optimized cash flow. Leveraging real-time sales data and demand forecasting enables precise inventory levels, enhancing product availability while minimizing holding costs. These methods also streamline supply chain operations, increasing agility and responsiveness to market fluctuations.

Restocking: Essential Tactics for Store Operations

Restocking plays a critical role in retail store operations by ensuring that inventory levels on shelves are consistently maintained to meet customer demand and enhance shopping experiences. Effective restocking tactics include strategic shelf organization, timely inventory checks, and efficient backroom-to-floor workflows, all aimed at reducing stockouts and optimizing sales. Leveraging real-time data and automated restocking systems further streamlines operations, minimizes labor costs, and supports seamless inventory turnover.

Technology Solutions for Replenishment and Restocking

Advanced technology solutions for replenishment and restocking in retail leverage AI-driven demand forecasting, real-time inventory tracking, and automated ordering systems to optimize stock levels and reduce out-of-stock incidents. IoT sensors and RFID technology enable continuous monitoring of product shelf status and trigger timely replenishment requests, enhancing operational efficiency. Integrating these technologies with ERP and POS systems allows seamless data synchronization, ensuring accurate inventory management and improved customer satisfaction.

Impact on Customer Experience: Replenishment vs Restocking

Replenishment ensures shelves remain consistently stocked by proactively forecasting demand and maintaining inventory flow, directly enhancing customer satisfaction with product availability. Restocking, a reactive process triggered by depleted inventory, may lead to temporary stockouts and negatively impact the shopping experience during peak hours. Efficient replenishment strategies reduce lost sales opportunities and foster brand loyalty by minimizing out-of-stock situations in retail environments.

Data-Driven Decision Making in Inventory Replenishment

Data-driven decision making in inventory replenishment leverages real-time sales data, historical trends, and predictive analytics to optimize stock levels, minimizing both overstock and stockouts. Utilizing advanced algorithms and machine learning models enables retailers to forecast demand accurately and trigger timely replenishment orders, enhancing supply chain efficiency. This approach differentiates from traditional restocking by proactively anticipating customer needs rather than reactively refilling inventory.

Best Practices for Balancing Stock Levels

Effective replenishment involves forecasting demand accurately and timing orders to maintain optimal inventory turnover, whereas restocking focuses on physically refilling shelves to ensure product availability. Best practices for balancing stock levels include leveraging real-time sales data, implementing automated inventory management systems, and setting reorder points based on variable lead times. Prioritizing these strategies minimizes stockouts and overstocks, enhancing customer satisfaction and operational efficiency.

Future Trends in Retail Replenishment and Restocking

Future trends in retail replenishment and restocking emphasize automated inventory management powered by AI and machine learning to predict demand with greater accuracy. Smart shelves, IoT sensors, and real-time data analytics enable dynamic restocking schedules, minimizing stockouts and excess inventory. Blockchain technology enhances transparency and traceability in supply chains, streamlining replenishment processes and reducing operational costs.

replenishment vs restocking Infographic

difterm.com

difterm.com