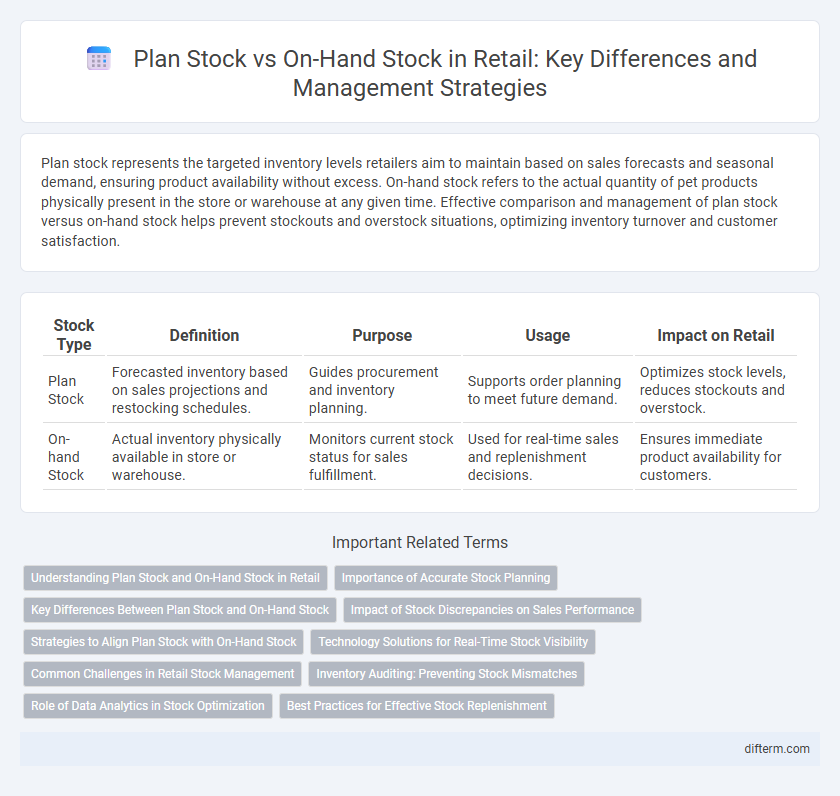

Plan stock represents the targeted inventory levels retailers aim to maintain based on sales forecasts and seasonal demand, ensuring product availability without excess. On-hand stock refers to the actual quantity of pet products physically present in the store or warehouse at any given time. Effective comparison and management of plan stock versus on-hand stock helps prevent stockouts and overstock situations, optimizing inventory turnover and customer satisfaction.

Table of Comparison

| Stock Type | Definition | Purpose | Usage | Impact on Retail |

|---|---|---|---|---|

| Plan Stock | Forecasted inventory based on sales projections and restocking schedules. | Guides procurement and inventory planning. | Supports order planning to meet future demand. | Optimizes stock levels, reduces stockouts and overstock. |

| On-hand Stock | Actual inventory physically available in store or warehouse. | Monitors current stock status for sales fulfillment. | Used for real-time sales and replenishment decisions. | Ensures immediate product availability for customers. |

Understanding Plan Stock and On-Hand Stock in Retail

Plan Stock represents the forecasted inventory levels based on sales projections and replenishment schedules, ensuring product availability aligns with demand trends. On-Hand Stock refers to the actual physical inventory present in stores or warehouses at a given time, critical for fulfilling immediate customer orders. Accurate synchronization between Plan Stock and On-Hand Stock optimizes inventory management, reducing stockouts and excess inventory costs.

Importance of Accurate Stock Planning

Accurate stock planning ensures the alignment between plan stock and on-hand stock, minimizing stockouts and overstock situations that impact retail profitability. Efficient synchronization of inventory levels supports demand forecasting, reduces carrying costs, and enhances customer satisfaction through timely product availability. Retailers leveraging precise stock data improve supply chain responsiveness and optimize replenishment strategies to maximize sales opportunities.

Key Differences Between Plan Stock and On-Hand Stock

Plan stock represents the projected inventory levels based on sales forecasts, purchase orders, and planned replenishments, while on-hand stock reflects the actual physical inventory available in the retail store or warehouse. The key difference lies in plan stock being forward-looking and used for inventory planning and demand management, whereas on-hand stock provides real-time data essential for immediate sales and operations decisions. Accurate synchronization between plan stock and on-hand stock is critical to optimizing inventory turnover, reducing stockouts, and enhancing overall supply chain efficiency in retail.

Impact of Stock Discrepancies on Sales Performance

Stock discrepancies between plan stock and on-hand stock lead to inaccurate inventory levels, causing stockouts or overstock situations that directly affect sales performance. Retailers experience lost revenue from missed sales opportunities when on-hand stock falls short of plan stock, while excess inventory increases holding costs and reduces cash flow efficiency. Accurate alignment of plan and on-hand stock optimizes product availability and maximizes sales conversion rates.

Strategies to Align Plan Stock with On-Hand Stock

Strategies to align plan stock with on-hand stock involve accurate demand forecasting using historical sales data and market trends to minimize stock discrepancies. Implementing real-time inventory tracking systems enhances visibility, allowing for timely adjustments in replenishment and reducing stockouts or overstock situations. Collaborative planning between sales, procurement, and warehouse teams ensures synchronization of stock levels with sales forecasts, optimizing inventory turnover and improving customer satisfaction.

Technology Solutions for Real-Time Stock Visibility

Technology solutions like RFID and IoT sensors enhance real-time stock visibility by providing accurate data on on-hand stock compared to planned stock levels. Advanced inventory management systems integrate AI-driven analytics to predict discrepancies and optimize stock replenishment strategies. Cloud-based platforms enable seamless synchronization of stock information across multiple retail locations, reducing stockouts and overstock scenarios.

Common Challenges in Retail Stock Management

Plan stock often deviates from on-hand stock due to inaccuracies in demand forecasting and supplier lead time variability, leading to frequent stockouts or overstock situations. Retailers struggle to synchronize inventory data across multiple channels, causing discrepancies that impact sales and customer satisfaction. Inefficient stock turnover and inadequate real-time visibility further complicate the effective management of both planned and actual inventory levels.

Inventory Auditing: Preventing Stock Mismatches

Accurate inventory auditing ensures alignment between Plan Stock, the forecasted inventory levels based on sales projections, and On-hand Stock, the actual physical count in retail stores. Discrepancies often arise from data entry errors, theft, or supply chain delays, causing stock mismatches that impact sales and customer satisfaction. Implementing regular cycle counts and integrating real-time inventory management systems minimizes the risk of stock variances, optimizing stock replenishment and reducing stockouts or overstock scenarios.

Role of Data Analytics in Stock Optimization

Data analytics plays a pivotal role in optimizing retail stock by accurately comparing planned stock levels against on-hand inventory to reduce overstock and stockouts. Advanced algorithms analyze historical sales data, seasonality, and demand patterns to adjust stock plans in real-time, enhancing inventory turnover and customer satisfaction. Predictive analytics enables retailers to make informed decisions on replenishment and allocation, driving operational efficiency and minimizing carrying costs.

Best Practices for Effective Stock Replenishment

Accurate comparison between plan stock and on-hand stock is vital for effective stock replenishment in retail, ensuring optimal inventory levels that meet consumer demand without overstocking. Employing real-time inventory tracking systems and demand forecasting tools helps maintain alignment between projected purchase needs and actual stock availability. Regular audits and data-driven adjustments improve replenishment accuracy, reduce stockouts, and enhance overall supply chain efficiency.

Plan Stock vs On-hand Stock Infographic

difterm.com

difterm.com