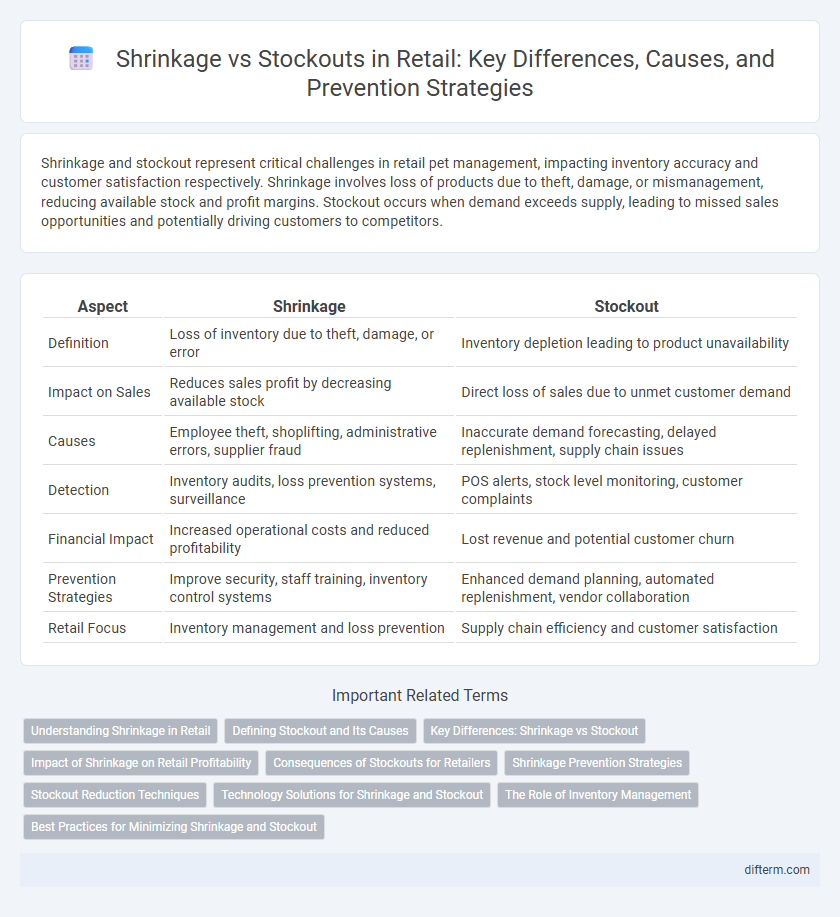

Shrinkage and stockout represent critical challenges in retail pet management, impacting inventory accuracy and customer satisfaction respectively. Shrinkage involves loss of products due to theft, damage, or mismanagement, reducing available stock and profit margins. Stockout occurs when demand exceeds supply, leading to missed sales opportunities and potentially driving customers to competitors.

Table of Comparison

| Aspect | Shrinkage | Stockout |

|---|---|---|

| Definition | Loss of inventory due to theft, damage, or error | Inventory depletion leading to product unavailability |

| Impact on Sales | Reduces sales profit by decreasing available stock | Direct loss of sales due to unmet customer demand |

| Causes | Employee theft, shoplifting, administrative errors, supplier fraud | Inaccurate demand forecasting, delayed replenishment, supply chain issues |

| Detection | Inventory audits, loss prevention systems, surveillance | POS alerts, stock level monitoring, customer complaints |

| Financial Impact | Increased operational costs and reduced profitability | Lost revenue and potential customer churn |

| Prevention Strategies | Improve security, staff training, inventory control systems | Enhanced demand planning, automated replenishment, vendor collaboration |

| Retail Focus | Inventory management and loss prevention | Supply chain efficiency and customer satisfaction |

Understanding Shrinkage in Retail

Shrinkage in retail refers to the loss of inventory due to theft, damage, or administrative errors, directly impacting profit margins. Unlike stockouts, which occur when demand exceeds supply causing missed sales opportunities, shrinkage reduces the actual available stock without replenishment options. Understanding the causes and effects of shrinkage is crucial for retailers to implement effective loss prevention strategies and maintain accurate inventory levels.

Defining Stockout and Its Causes

Stockout occurs when inventory levels are insufficient to meet customer demand, resulting in lost sales and diminished customer satisfaction. Common causes of stockouts include inaccurate demand forecasting, supply chain disruptions, and delays in replenishment due to supplier issues. Effective inventory management and real-time tracking systems help mitigate stockouts by aligning stock availability with consumer purchasing patterns.

Key Differences: Shrinkage vs Stockout

Shrinkage refers to the loss of inventory due to theft, damage, or administrative errors, directly impacting a retailer's profit margins by reducing available stock. Stockout occurs when demand exceeds inventory, leading to missed sales opportunities and decreased customer satisfaction. Unlike shrinkage, which involves inventory loss without sales, stockouts stem from insufficient inventory replenishment or inaccurate demand forecasting.

Impact of Shrinkage on Retail Profitability

Shrinkage directly reduces retail profitability by causing lost inventory that cannot be sold, resulting in decreased revenue and increased operational costs. Unlike stockouts, which lead to missed sales opportunities and potential customer dissatisfaction, shrinkage erodes profit margins through theft, damage, or administrative errors. Controlling shrinkage is essential for maintaining accurate inventory levels and preserving retail profit margins.

Consequences of Stockouts for Retailers

Stockouts in retail lead to significant lost sales, diminished customer loyalty, and damaged brand reputation, directly impacting revenue and profitability. Retailers face increased operational costs as they rush to replenish out-of-stock items and manage dissatisfied customers. Persistent stockouts can drive shoppers to competitors, eroding market share and hindering long-term business growth.

Shrinkage Prevention Strategies

Shrinkage prevention strategies in retail focus on reducing inventory loss due to theft, damage, or administrative errors, directly impacting profitability by maintaining accurate stock levels. Implementing advanced inventory management systems, employee training programs, and enhanced surveillance technologies effectively minimize shrinkage incidents. These strategies ensure product availability, mitigate financial losses, and improve overall operational efficiency.

Stockout Reduction Techniques

Implementing real-time inventory tracking systems and demand forecasting models significantly reduces stockouts by enabling retailers to anticipate product shortages accurately. Employing automated replenishment tools and safety stock algorithms ensures timely restocking, preventing lost sales and customer dissatisfaction. Enhancing supplier collaboration and using RFID technology streamline supply chain visibility, further minimizing stockout risks in retail environments.

Technology Solutions for Shrinkage and Stockout

Advanced technology solutions such as RFID tagging and real-time inventory management systems play a crucial role in minimizing retail shrinkage by enabling precise tracking of stock movement and deterring theft. Predictive analytics and AI-powered demand forecasting help prevent stockouts by optimizing inventory levels and ensuring product availability. Integrating IoT sensors with cloud-based platforms enhances visibility across the supply chain, reducing both shrinkage and stockouts through timely alerts and automated replenishment processes.

The Role of Inventory Management

Effective inventory management plays a crucial role in balancing shrinkage and stockouts by optimizing stock levels to minimize losses and ensure product availability. Implementing real-time tracking systems and demand forecasting tools enables retailers to detect discrepancies early, reducing shrinkage caused by theft, damage, or errors. Maintaining accurate inventory records with advanced software helps prevent stockouts, enhancing customer satisfaction and driving sales growth.

Best Practices for Minimizing Shrinkage and Stockout

Implement rigorous inventory management using real-time tracking systems and frequent cycle counts to reduce both shrinkage and stockouts in retail environments. Employ loss prevention strategies such as employee training, surveillance, and secure storage to minimize shrinkage risks, while optimizing demand forecasting and automated replenishment to prevent stockouts. Enhance transparency across the supply chain to quickly identify discrepancies, ensuring accurate stock levels and improving overall inventory accuracy.

Shrinkage vs Stockout Infographic

difterm.com

difterm.com