Deadstock in retail pet refers to products that have never sold and remain unsold for extended periods, often resulting in wasted shelf space and capital. Slow-moving inventory consists of items that sell infrequently but still generate occasional sales, requiring strategic promotions or markdowns to clear stock effectively. Managing both types efficiently is crucial to optimize cash flow and maintain a fresh, appealing product assortment for pet owners.

Table of Comparison

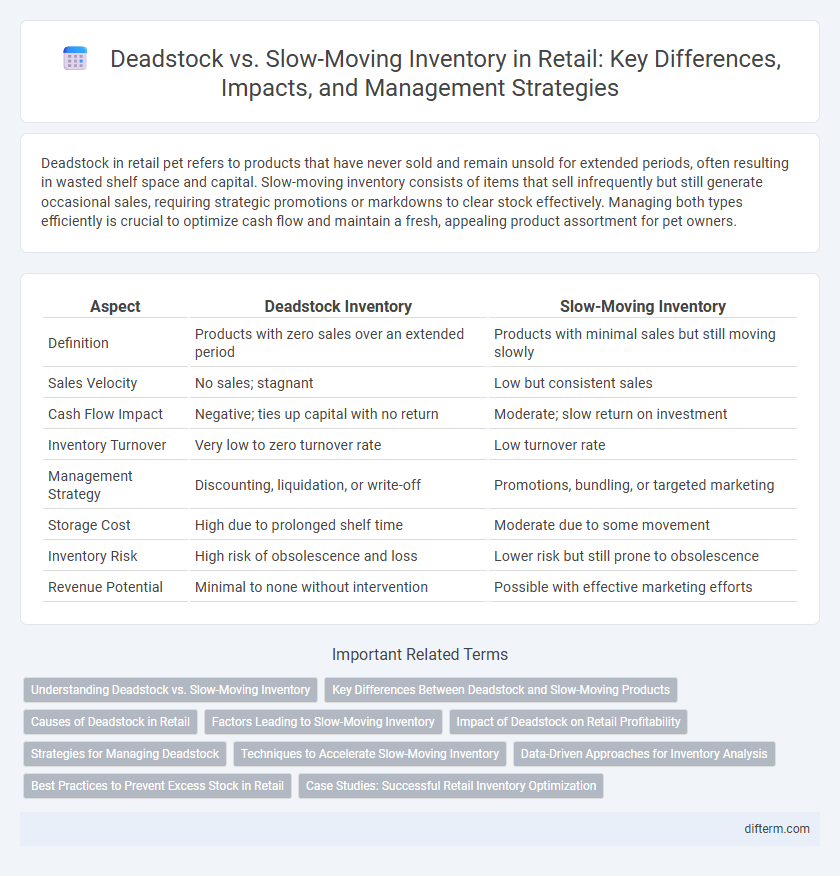

| Aspect | Deadstock Inventory | Slow-Moving Inventory |

|---|---|---|

| Definition | Products with zero sales over an extended period | Products with minimal sales but still moving slowly |

| Sales Velocity | No sales; stagnant | Low but consistent sales |

| Cash Flow Impact | Negative; ties up capital with no return | Moderate; slow return on investment |

| Inventory Turnover | Very low to zero turnover rate | Low turnover rate |

| Management Strategy | Discounting, liquidation, or write-off | Promotions, bundling, or targeted marketing |

| Storage Cost | High due to prolonged shelf time | Moderate due to some movement |

| Inventory Risk | High risk of obsolescence and loss | Lower risk but still prone to obsolescence |

| Revenue Potential | Minimal to none without intervention | Possible with effective marketing efforts |

Understanding Deadstock vs. Slow-Moving Inventory

Deadstock refers to products that have never sold and remain in inventory, often due to seasonality, outdated trends, or over-purchasing, while slow-moving inventory consists of items selling at a much slower rate than expected but still generate occasional sales. Efficient inventory management requires distinguishing deadstock to avoid holding costs and prevent cash flow issues, whereas slow-moving goods can be strategically discounted or promoted to boost turnover. Retailers leveraging accurate sales data and demand forecasting can optimize stock levels, reduce deadstock risk, and improve profitability through targeted actions on slow-moving inventory.

Key Differences Between Deadstock and Slow-Moving Products

Deadstock refers to inventory that has never been sold and is unlikely to sell due to obsolescence or lack of demand, while slow-moving products are items that sell at a much slower rate compared to other stock but still have some sales activity. Deadstock typically occupies warehouse space without generating revenue and often requires discounting or clearance strategies to liquidate. Slow-moving inventory can provide insights into customer preferences and may be rejuvenated through targeted promotions or repositioning within the retail mix.

Causes of Deadstock in Retail

Deadstock in retail primarily results from inaccurate demand forecasting, seasonal changes, and shifts in consumer preferences that leave products unsold. Overstocking due to poor inventory management and abrupt market trends also contribute significantly to accumulating deadstock. Ineffective marketing strategies and lack of product differentiation further exacerbate the problem, causing retailers to struggle with excess inventory that ties up capital.

Factors Leading to Slow-Moving Inventory

Slow-moving inventory in retail often results from factors such as inaccurate demand forecasting, seasonal fluctuations, and ineffective marketing strategies. Poor product assortment and changes in consumer preferences also contribute significantly to stock lingering on shelves. Unlike deadstock, which remains unsold indefinitely, slow-moving items may eventually sell but tie up capital and storage space inefficiently.

Impact of Deadstock on Retail Profitability

Deadstock in retail significantly reduces profitability by tying up capital and storage space without generating revenue, unlike slow-moving inventory that at least contributes marginally through occasional sales. High levels of deadstock increase holding costs, markdowns, and write-offs, negatively impacting cash flow and overall financial health. Effective inventory management and demand forecasting are critical to minimizing deadstock and preserving retail profit margins.

Strategies for Managing Deadstock

Effective strategies for managing deadstock in retail include implementing dynamic pricing models and targeted promotions to accelerate turnover and reduce holding costs. Utilizing data analytics to identify trends and adjust procurement can prevent future accumulation, while partnering with secondary markets or donation programs transforms deadstock into value. Integrating inventory management software enhances visibility, enabling timely decisions that optimize stock levels and improve cash flow.

Techniques to Accelerate Slow-Moving Inventory

Techniques to accelerate slow-moving inventory include dynamic pricing strategies like flash sales and discounts that create urgency and increase turnover rates. Implementing inventory segmentation and predictive analytics enables retailers to identify slow-moving SKUs and tailor marketing efforts effectively. Leveraging omnichannel distribution through online marketplaces and in-store promotions also enhances product visibility and stimulates faster sales.

Data-Driven Approaches for Inventory Analysis

Data-driven approaches for inventory analysis leverage advanced analytics and machine learning to distinguish deadstock--products with no sales over extended periods--from slow-moving inventory that sells gradually but inefficiently. Retailers use real-time sales data, historical trends, and predictive modeling to optimize stock levels, minimize carrying costs, and improve turnover rates. Integrating point-of-sale systems with inventory management software enables precise identification and strategic decision-making to reduce excess stock and enhance overall profitability.

Best Practices to Prevent Excess Stock in Retail

Implementing accurate demand forecasting using advanced analytics helps retailers minimize deadstock and slow-moving inventory by aligning purchases with consumer trends. Optimizing inventory turnover through real-time data tracking and adaptive replenishment strategies reduces excess stock while maintaining product availability. Incorporating flexible supply chain management and dynamic markdown pricing further prevents stock obsolescence and maximizes revenue in retail operations.

Case Studies: Successful Retail Inventory Optimization

Case studies in retail inventory optimization reveal strategies to convert deadstock--obsolete items with no sales velocity--into profitable assets through targeted promotions and dynamic pricing models. Successful retailers leverage real-time data analytics and AI-driven demand forecasting to identify slow-moving inventory early, enabling agile inventory adjustments and minimizing carrying costs. Implementing cross-channel inventory visibility and automated replenishment systems has consistently improved turnover rates and reduced markdowns, driving enhanced operational efficiency and profitability.

deadstock vs slow-moving inventory Infographic

difterm.com

difterm.com