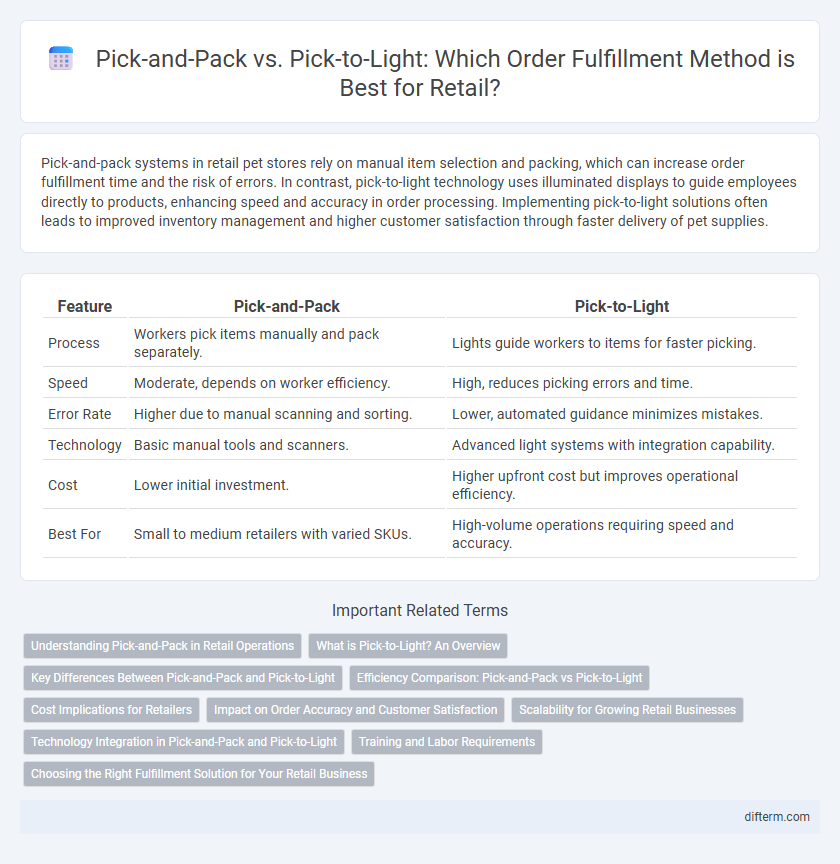

Pick-and-pack systems in retail pet stores rely on manual item selection and packing, which can increase order fulfillment time and the risk of errors. In contrast, pick-to-light technology uses illuminated displays to guide employees directly to products, enhancing speed and accuracy in order processing. Implementing pick-to-light solutions often leads to improved inventory management and higher customer satisfaction through faster delivery of pet supplies.

Table of Comparison

| Feature | Pick-and-Pack | Pick-to-Light |

|---|---|---|

| Process | Workers pick items manually and pack separately. | Lights guide workers to items for faster picking. |

| Speed | Moderate, depends on worker efficiency. | High, reduces picking errors and time. |

| Error Rate | Higher due to manual scanning and sorting. | Lower, automated guidance minimizes mistakes. |

| Technology | Basic manual tools and scanners. | Advanced light systems with integration capability. |

| Cost | Lower initial investment. | Higher upfront cost but improves operational efficiency. |

| Best For | Small to medium retailers with varied SKUs. | High-volume operations requiring speed and accuracy. |

Understanding Pick-and-Pack in Retail Operations

Pick-and-pack in retail operations involves manually selecting products from inventory and packing them for shipment or customer pickup, which streamlines order fulfillment by consolidating items efficiently. This method relies on accurate inventory management and employee training to reduce errors and improve speed, making it suitable for businesses with diverse product lines. Compared to pick-to-light systems, pick-and-pack offers flexibility but may require more labor input, balancing cost with operational complexity.

What is Pick-to-Light? An Overview

Pick-to-light is a warehouse order fulfillment technology that uses illuminated indicators to guide workers to the exact product locations, enhancing speed and accuracy. This system reduces errors compared to traditional pick-and-pack methods by providing real-time visual cues that streamline the picking process. Retailers leveraging pick-to-light experience increased operational efficiency, faster order processing, and improved inventory management.

Key Differences Between Pick-and-Pack and Pick-to-Light

Pick-and-pack involves manually selecting items from inventory and packing them for shipment, emphasizing accuracy and flexibility but often requiring more labor and time. Pick-to-light uses LED displays to guide workers to the correct bin locations, significantly increasing picking speed and reducing errors through visual cues. The main differences lie in technology integration, operational efficiency, and scalability, with pick-to-light offering automation benefits over the traditional pick-and-pack method.

Efficiency Comparison: Pick-and-Pack vs Pick-to-Light

Pick-to-light systems enhance order fulfillment efficiency by reducing picking errors and accelerating item retrieval through visual cues, compared to traditional pick-and-pack methods that rely heavily on manual verification and slower batch processing. Warehouses implementing pick-to-light report up to a 30% increase in picking speed and a 50% reduction in error rates, streamlining labor costs and boosting throughput. While pick-and-pack remains effective for low-volume or complex orders, pick-to-light's automation significantly optimizes high-volume, repetitive picking operations in retail environments.

Cost Implications for Retailers

Pick-and-pack systems generally require higher labor costs due to manual item selection and packing, leading to increased operational expenses for retailers. Pick-to-light technology reduces errors and speeds up fulfillment by guiding workers with visual cues, significantly lowering labor costs and boosting productivity. Although initial investment in pick-to-light infrastructure is higher, the long-term savings from reduced labor and improved accuracy enhance overall cost efficiency in retail operations.

Impact on Order Accuracy and Customer Satisfaction

Pick-and-pack systems often result in lower order accuracy compared to pick-to-light technology, leading to increased errors and customer dissatisfaction. Pick-to-light enhances order accuracy by providing real-time visual cues, significantly reducing picking mistakes and accelerating fulfillment. Improved accuracy directly boosts customer satisfaction through faster deliveries and fewer returns, essential for competitive retail environments.

Scalability for Growing Retail Businesses

Pick-and-pack systems offer flexibility for growing retail businesses by handling diverse product types but may face limitations in speed and efficiency as order volumes rise. Pick-to-light technology enhances scalability by accelerating order fulfillment with visual guidance, reducing errors and labor costs in high-demand environments. Retailers scaling operations benefit from integrating pick-to-light to maintain accuracy and speed during peak periods, outperforming traditional pick-and-pack workflows.

Technology Integration in Pick-and-Pack and Pick-to-Light

Technology integration in pick-and-pack systems relies heavily on barcode scanning and warehouse management software (WMS) to accurately track inventory and streamline order processing. Pick-to-light technology enhances efficiency by using LED indicators to guide operators to specific locations, reducing errors and increasing speed. Both systems benefit from real-time data analytics and IoT connectivity, but pick-to-light offers superior accuracy and reduced training time through its visual cues.

Training and Labor Requirements

Pick-and-pack requires extensive manual training for warehouse staff to accurately select and package items, often resulting in longer onboarding times and higher dependency on worker expertise. Pick-to-light systems significantly reduce training complexity by using illuminated displays that guide employees to the correct items, enabling faster adaptation and minimizing errors. Labor requirements decrease with pick-to-light technology due to streamlined workflows and less reliance on individual skill, improving overall operational efficiency.

Choosing the Right Fulfillment Solution for Your Retail Business

Pick-and-pack offers a straightforward, flexible approach ideal for small to mid-sized retail operations with diverse inventory, emphasizing accuracy through manual order verification. Pick-to-light systems enhance efficiency and reduce errors in high-volume warehouses by guiding workers with illuminated indicators, speeding up the picking process and improving order accuracy. Retailers should assess order volume, SKU complexity, and budget constraints to select the fulfillment solution that maximizes operational efficiency and customer satisfaction.

pick-and-pack vs pick-to-light Infographic

difterm.com

difterm.com