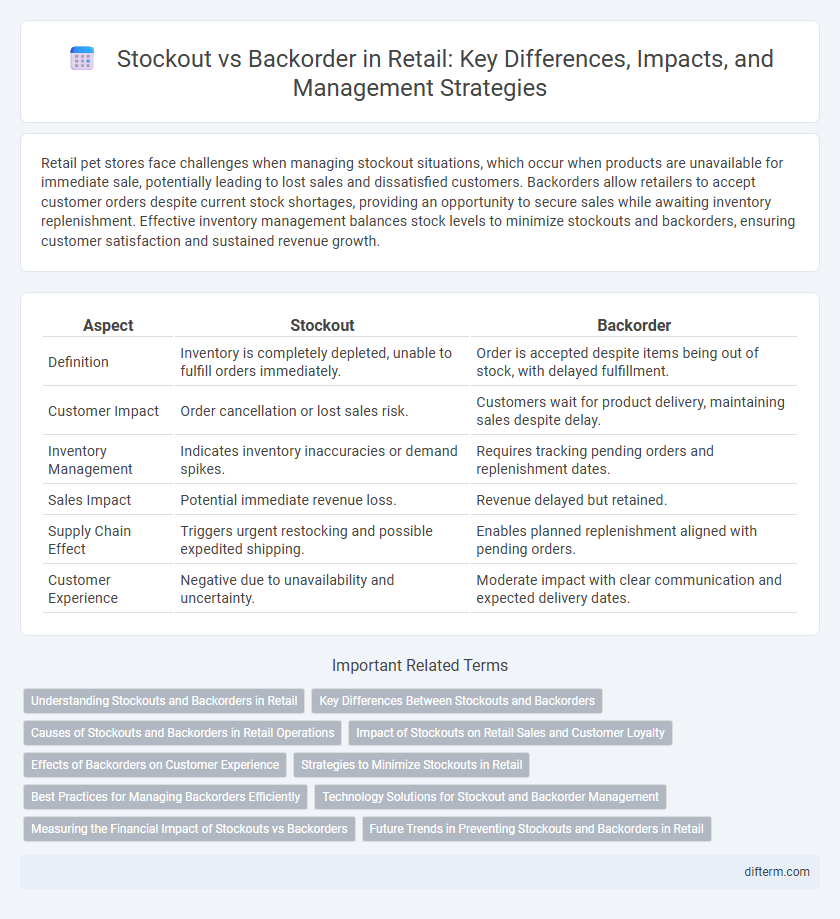

Retail pet stores face challenges when managing stockout situations, which occur when products are unavailable for immediate sale, potentially leading to lost sales and dissatisfied customers. Backorders allow retailers to accept customer orders despite current stock shortages, providing an opportunity to secure sales while awaiting inventory replenishment. Effective inventory management balances stock levels to minimize stockouts and backorders, ensuring customer satisfaction and sustained revenue growth.

Table of Comparison

| Aspect | Stockout | Backorder |

|---|---|---|

| Definition | Inventory is completely depleted, unable to fulfill orders immediately. | Order is accepted despite items being out of stock, with delayed fulfillment. |

| Customer Impact | Order cancellation or lost sales risk. | Customers wait for product delivery, maintaining sales despite delay. |

| Inventory Management | Indicates inventory inaccuracies or demand spikes. | Requires tracking pending orders and replenishment dates. |

| Sales Impact | Potential immediate revenue loss. | Revenue delayed but retained. |

| Supply Chain Effect | Triggers urgent restocking and possible expedited shipping. | Enables planned replenishment aligned with pending orders. |

| Customer Experience | Negative due to unavailability and uncertainty. | Moderate impact with clear communication and expected delivery dates. |

Understanding Stockouts and Backorders in Retail

Stockouts occur when retail inventory runs out, causing immediate sales loss and potential customer dissatisfaction. Backorders allow retailers to accept orders despite stock unavailability, postponing fulfillment until replenishment arrives. Efficient inventory management and demand forecasting reduce stockouts and backorders, optimizing customer experience and operational efficiency.

Key Differences Between Stockouts and Backorders

Stockouts occur when inventory is completely depleted, preventing immediate product availability, whereas backorders allow customers to place orders for out-of-stock items that will be shipped once replenished. Stockouts typically result in lost sales and diminished customer satisfaction, while backorders maintain demand continuity but may extend delivery timelines. Efficient inventory management systems monitor stock levels to minimize stockouts and manage backorders, balancing supply chain responsiveness and customer expectations.

Causes of Stockouts and Backorders in Retail Operations

Stockouts in retail often result from inaccurate demand forecasting, supplier delays, and insufficient inventory management systems. Backorders typically arise when demand exceeds current stock levels, exacerbated by supply chain disruptions and production delays. Both scenarios highlight the importance of real-time inventory tracking and robust supplier relationships to minimize sales loss and customer dissatisfaction.

Impact of Stockouts on Retail Sales and Customer Loyalty

Stockouts in retail significantly reduce sales revenue by causing immediate loss of purchase opportunities and shifting customer demand to competitors. Frequent stockouts erode customer trust and loyalty, leading to long-term declines in repeat business and brand reputation. Implementing backorder systems can mitigate these effects by allowing customers to secure products despite inventory shortages, preserving sales and maintaining customer satisfaction.

Effects of Backorders on Customer Experience

Backorders in retail often lead to delayed delivery times and increased customer frustration, negatively impacting customer satisfaction and brand loyalty. Extended backorder durations can cause inventory uncertainty, reducing trust and prompting customers to seek alternative retailers. Effective communication and accurate backorder updates are crucial for mitigating negative customer experiences and maintaining retention rates.

Strategies to Minimize Stockouts in Retail

Implementing real-time inventory tracking systems and demand forecasting analytics helps retailers anticipate product demand and prevent stockouts. Collaborating closely with suppliers to ensure flexible replenishment schedules and maintaining safety stock levels can reduce backorder occurrences. Leveraging omnichannel fulfillment strategies enhances product availability and customer satisfaction by efficiently managing stock distribution across channels.

Best Practices for Managing Backorders Efficiently

Efficient backorder management in retail involves transparent communication with customers about expected delays and potential alternatives to maintain satisfaction. Implementing real-time inventory tracking and automated backorder alerts helps prevent stockouts and streamline order fulfillment. Prioritizing backorders based on customer value and product demand optimizes warehouse operations and revenue retention.

Technology Solutions for Stockout and Backorder Management

Technology solutions such as AI-driven inventory management systems optimize stock levels by predicting demand patterns and minimizing stockouts in retail environments. Backorder management platforms integrate real-time tracking and automated customer notifications to improve order fulfillment transparency and reduce wait times. Cloud-based systems enhance scalability and data accuracy, enabling retailers to swiftly address supply chain disruptions and maintain customer satisfaction.

Measuring the Financial Impact of Stockouts vs Backorders

Stockouts result in immediate lost sales and decreased customer satisfaction, directly impacting revenue and brand loyalty. Backorders, while delaying fulfillment, preserve sales opportunities but increase carrying costs, administrative expenses, and potential order cancellations. Accurately measuring the financial impact involves analyzing lost profit margins from stockouts against additional costs and customer retention rates associated with backorders.

Future Trends in Preventing Stockouts and Backorders in Retail

Future trends in preventing stockouts and backorders in retail emphasize advanced AI-driven demand forecasting and real-time inventory management systems. Integration of IoT devices enhances supply chain visibility, enabling proactive restocking and minimizing disruptions. Retailers increasingly adopt automated replenishment solutions combined with blockchain technology to ensure transparency and reduce fulfillment delays.

stockout vs backorder Infographic

difterm.com

difterm.com