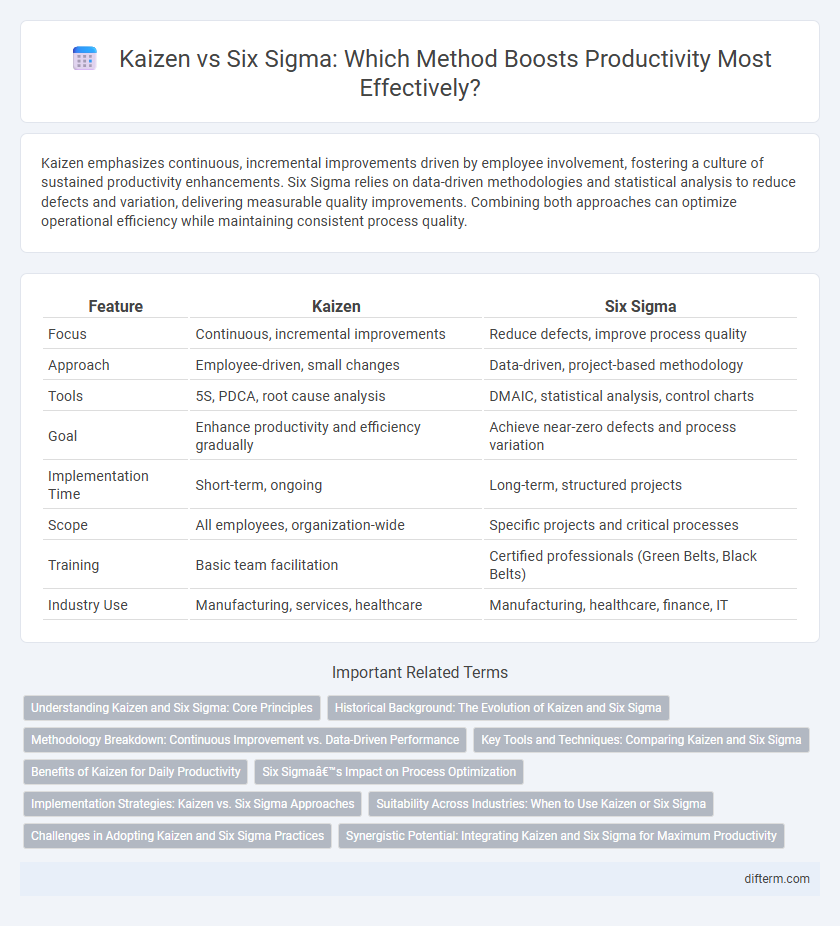

Kaizen emphasizes continuous, incremental improvements driven by employee involvement, fostering a culture of sustained productivity enhancements. Six Sigma relies on data-driven methodologies and statistical analysis to reduce defects and variation, delivering measurable quality improvements. Combining both approaches can optimize operational efficiency while maintaining consistent process quality.

Table of Comparison

| Feature | Kaizen | Six Sigma |

|---|---|---|

| Focus | Continuous, incremental improvements | Reduce defects, improve process quality |

| Approach | Employee-driven, small changes | Data-driven, project-based methodology |

| Tools | 5S, PDCA, root cause analysis | DMAIC, statistical analysis, control charts |

| Goal | Enhance productivity and efficiency gradually | Achieve near-zero defects and process variation |

| Implementation Time | Short-term, ongoing | Long-term, structured projects |

| Scope | All employees, organization-wide | Specific projects and critical processes |

| Training | Basic team facilitation | Certified professionals (Green Belts, Black Belts) |

| Industry Use | Manufacturing, services, healthcare | Manufacturing, healthcare, finance, IT |

Understanding Kaizen and Six Sigma: Core Principles

Kaizen emphasizes continuous, incremental improvements driven by all employees to enhance productivity and efficiency consistently. Six Sigma focuses on reducing defects and variability using data-driven methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) to achieve near-perfect process quality. Both methodologies aim to optimize business processes but differ in scope, with Kaizen promoting ongoing small changes and Six Sigma targeting specific problem-solving with statistical rigor.

Historical Background: The Evolution of Kaizen and Six Sigma

Kaizen originated in post-World War II Japan as a continuous improvement philosophy emphasizing small, incremental changes driven by all employees. Six Sigma was developed in the 1980s by Motorola to reduce process variation and defects through statistical methods and rigorous project management. Both methodologies evolved to enhance productivity but differ in origin, approach, and implementation focus.

Methodology Breakdown: Continuous Improvement vs. Data-Driven Performance

Kaizen emphasizes continuous, incremental improvements through employee involvement and iterative feedback, fostering a culture of ongoing productivity enhancement. Six Sigma relies on data-driven performance analysis using statistical tools to identify defects and reduce process variation, aiming for near-perfect quality. Both methodologies focus on improving efficiency but differ in execution: Kaizen through gradual, participative changes and Six Sigma through rigorous, quantifiable problem-solving.

Key Tools and Techniques: Comparing Kaizen and Six Sigma

Kaizen emphasizes continuous improvement through small, incremental changes using tools like 5S, Gemba walks, and PDCA cycles, fostering employee involvement at all levels. Six Sigma focuses on reducing defects and variability with data-driven techniques such as DMAIC, statistical process control (SPC), and root cause analysis, often led by certified Black Belts. Both methodologies utilize problem-solving frameworks, but Six Sigma relies more heavily on quantitative analysis, while Kaizen promotes cultural and procedural shifts.

Benefits of Kaizen for Daily Productivity

Kaizen enhances daily productivity by fostering continuous, incremental improvements that empower employees to identify and solve problems on the spot, leading to reduced waste and increased efficiency. Its focus on small, manageable changes promotes a culture of sustained engagement and teamwork, which improves workflow and minimizes downtime. Kaizen's emphasis on employee involvement and standardized processes results in consistent quality improvements and faster adaptation to operational challenges.

Six Sigma’s Impact on Process Optimization

Six Sigma's impact on process optimization is profound, leveraging data-driven methodologies to reduce defects and variability in manufacturing and service processes. By applying DMAIC (Define, Measure, Analyze, Improve, Control) cycles, organizations enhance efficiency, improve quality, and achieve consistent process outcomes. This structured approach results in measurable cost savings, higher customer satisfaction, and sustained productivity improvements.

Implementation Strategies: Kaizen vs. Six Sigma Approaches

Kaizen emphasizes continuous, incremental improvements through employee involvement at all levels, fostering a culture of sustained productivity enhancement. Six Sigma implements a data-driven, structured methodology focused on identifying and eliminating defects, utilizing DMAIC (Define, Measure, Analyze, Improve, Control) to achieve measurable quality improvements. While Kaizen encourages small, ongoing changes, Six Sigma targets significant process improvements through rigorous statistical analysis and project-based initiatives.

Suitability Across Industries: When to Use Kaizen or Six Sigma

Kaizen, emphasizing continuous incremental improvements, is most suitable for industries aiming to foster a culture of ongoing employee-driven enhancements, such as manufacturing, healthcare, and service sectors. Six Sigma, with its data-driven approach to reducing variability and defects, excels in highly regulated industries like automotive, aerospace, and finance where precision and compliance are critical. Organizations often deploy Kaizen for gradual process refinement and Six Sigma for solving complex quality issues requiring statistical analysis, optimizing productivity based on industry-specific demands.

Challenges in Adopting Kaizen and Six Sigma Practices

Challenges in adopting Kaizen and Six Sigma practices often include resistance to cultural change and the need for continuous employee involvement. Kaizen requires sustained incremental improvements, which can be hindered by inconsistent commitment and inadequate training. Six Sigma faces difficulties in data accuracy, complexity of statistical tools, and aligning projects with strategic business goals.

Synergistic Potential: Integrating Kaizen and Six Sigma for Maximum Productivity

Integrating Kaizen and Six Sigma leverages continuous incremental improvements with data-driven problem-solving, creating a powerful synergy that enhances overall productivity. Kaizen's focus on employee-driven, small-scale changes complements Six Sigma's structured methodology targeting defect reduction and process consistency. This combination accelerates operational excellence by fostering a culture of ongoing refinement supported by rigorous analysis, driving sustained performance gains.

Kaizen vs Six Sigma Infographic

difterm.com

difterm.com