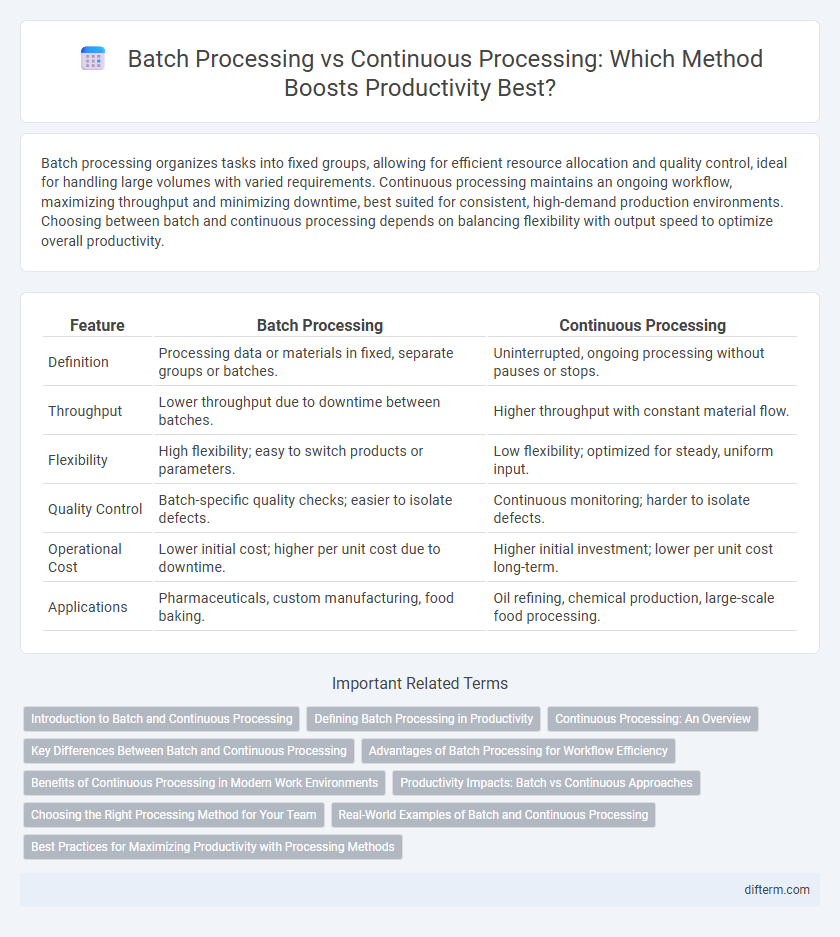

Batch processing organizes tasks into fixed groups, allowing for efficient resource allocation and quality control, ideal for handling large volumes with varied requirements. Continuous processing maintains an ongoing workflow, maximizing throughput and minimizing downtime, best suited for consistent, high-demand production environments. Choosing between batch and continuous processing depends on balancing flexibility with output speed to optimize overall productivity.

Table of Comparison

| Feature | Batch Processing | Continuous Processing |

|---|---|---|

| Definition | Processing data or materials in fixed, separate groups or batches. | Uninterrupted, ongoing processing without pauses or stops. |

| Throughput | Lower throughput due to downtime between batches. | Higher throughput with constant material flow. |

| Flexibility | High flexibility; easy to switch products or parameters. | Low flexibility; optimized for steady, uniform input. |

| Quality Control | Batch-specific quality checks; easier to isolate defects. | Continuous monitoring; harder to isolate defects. |

| Operational Cost | Lower initial cost; higher per unit cost due to downtime. | Higher initial investment; lower per unit cost long-term. |

| Applications | Pharmaceuticals, custom manufacturing, food baking. | Oil refining, chemical production, large-scale food processing. |

Introduction to Batch and Continuous Processing

Batch processing involves handling large volumes of data or tasks in grouped sets, maximizing efficiency by processing similar items collectively during scheduled intervals. Continuous processing maintains an uninterrupted flow, enabling real-time data handling and immediate output, which is essential in industries requiring constant throughput like manufacturing or data streaming. Understanding these approaches enables businesses to optimize operational workflows by selecting the method aligned with their productivity and processing speed requirements.

Defining Batch Processing in Productivity

Batch processing is a productivity method where tasks or data are collected and processed as a single group, enhancing efficiency by minimizing setup and downtime. This approach is ideal for repetitive tasks with predictable workloads, enabling better resource management and throughput optimization. Batch processing improves overall productivity by allowing systems to handle large volumes systematically without constant human intervention.

Continuous Processing: An Overview

Continuous processing maximizes productivity by maintaining an uninterrupted flow of materials through the production system, significantly reducing downtime associated with batch changes. This method enhances efficiency, consistency, and scalability, especially in industries such as chemicals, pharmaceuticals, and food processing where steady-state operations are critical. Advanced automation and real-time monitoring technologies further optimize continuous processing by enabling precise control and immediate adjustments to process variables.

Key Differences Between Batch and Continuous Processing

Batch processing involves handling large groups of items simultaneously, while continuous processing manages materials continuously without interruption. Batch processing offers flexibility by allowing customization per batch and easier quality control, whereas continuous processing emphasizes higher efficiency, consistent output, and reduced labor costs. Key differences include throughput speed, operational complexity, and suitability for different production scales and product types.

Advantages of Batch Processing for Workflow Efficiency

Batch processing enhances workflow efficiency by allowing the grouping of similar tasks, reducing setup times and minimizing interruptions. It enables better resource allocation and easier error detection since processes are executed in defined batches. This method also facilitates bulk data handling, improving throughput and streamlining task management in complex production environments.

Benefits of Continuous Processing in Modern Work Environments

Continuous processing in modern work environments enhances productivity by minimizing downtime and streamlining workflows, allowing for real-time data analysis and faster decision-making. It enables seamless integration with automated systems and IoT devices, promoting higher efficiency and consistent output quality. This approach reduces bottlenecks and supports scalable operations, essential for industries requiring rapid responsiveness and adaptability.

Productivity Impacts: Batch vs Continuous Approaches

Batch processing allows for processing large volumes of work in set intervals, optimizing resource allocation and reducing downtime between tasks. Continuous processing ensures a steady flow of operations, minimizing wait times and increasing throughput by maintaining consistent production rates. The choice between batch and continuous approaches significantly impacts overall productivity, with batch processing suited for variability and continuous processing favoring uniform demand and constant output.

Choosing the Right Processing Method for Your Team

Selecting the appropriate processing method depends on your team's workload, project complexity, and deadlines. Batch processing suits tasks that can be grouped and handled simultaneously, maximizing efficiency for repetitive activities, while continuous processing excels in real-time operations requiring constant data flow and immediate feedback. Evaluate the nature of your team's tasks and resource availability to optimize productivity and streamline workflows effectively.

Real-World Examples of Batch and Continuous Processing

Batch processing is exemplified by payroll systems where employee salaries are calculated and distributed at scheduled intervals, ensuring accurate and organized compensation management. Continuous processing is illustrated by petroleum refining, where raw materials are processed non-stop to maintain a steady output of fuel products. These real-world examples highlight how batch processing suits discrete, periodic tasks while continuous processing enhances efficiency in constant, large-scale production environments.

Best Practices for Maximizing Productivity with Processing Methods

Batch processing maximizes productivity by grouping similar tasks to reduce setup time and enhance resource utilization, making it ideal for large volumes with predictable workflows. Continuous processing delivers real-time output and minimizes downtime by maintaining constant operation, fitting best for processes requiring steady, uninterrupted production. Optimal productivity balances batch processing for efficiency in bulk tasks and continuous processing for responsiveness, tailored to specific industry demands and operational goals.

batch processing vs continuous processing Infographic

difterm.com

difterm.com