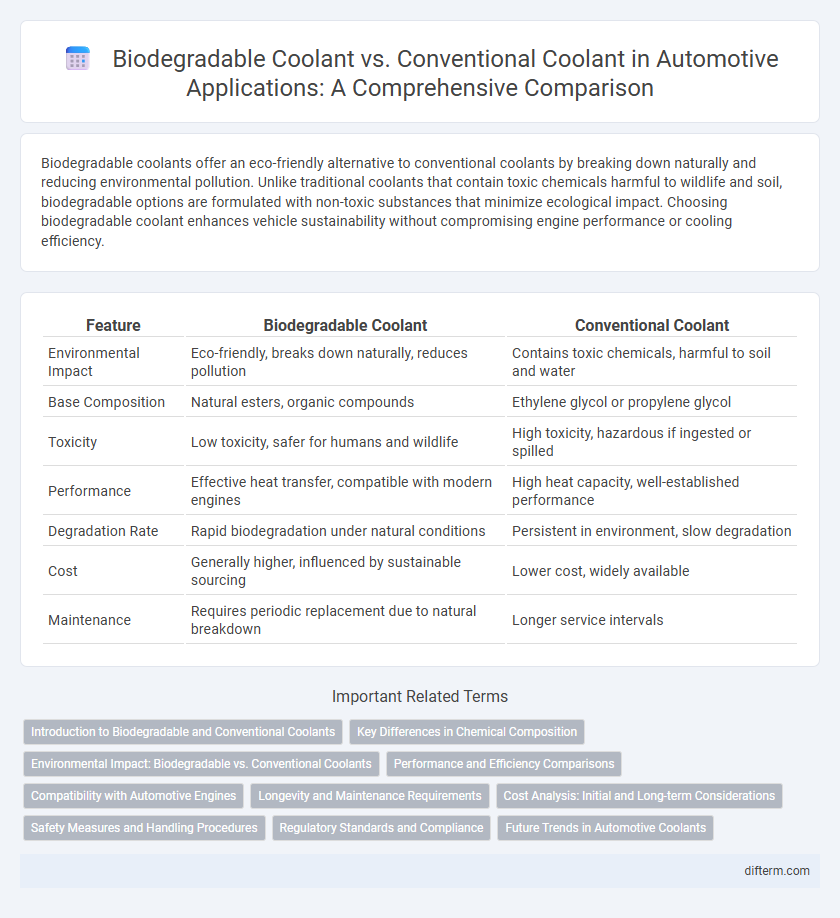

Biodegradable coolants offer an eco-friendly alternative to conventional coolants by breaking down naturally and reducing environmental pollution. Unlike traditional coolants that contain toxic chemicals harmful to wildlife and soil, biodegradable options are formulated with non-toxic substances that minimize ecological impact. Choosing biodegradable coolant enhances vehicle sustainability without compromising engine performance or cooling efficiency.

Table of Comparison

| Feature | Biodegradable Coolant | Conventional Coolant |

|---|---|---|

| Environmental Impact | Eco-friendly, breaks down naturally, reduces pollution | Contains toxic chemicals, harmful to soil and water |

| Base Composition | Natural esters, organic compounds | Ethylene glycol or propylene glycol |

| Toxicity | Low toxicity, safer for humans and wildlife | High toxicity, hazardous if ingested or spilled |

| Performance | Effective heat transfer, compatible with modern engines | High heat capacity, well-established performance |

| Degradation Rate | Rapid biodegradation under natural conditions | Persistent in environment, slow degradation |

| Cost | Generally higher, influenced by sustainable sourcing | Lower cost, widely available |

| Maintenance | Requires periodic replacement due to natural breakdown | Longer service intervals |

Introduction to Biodegradable and Conventional Coolants

Biodegradable coolants, formulated with environmentally friendly organic compounds, offer efficient heat transfer while minimizing ecological impact through rapid decomposition in natural environments. Conventional coolants commonly contain ethylene glycol and heavy metals, providing robust thermal management but posing significant environmental hazards due to their toxicity and persistence. The growing automotive demand for sustainable materials has accelerated the adoption of biodegradable coolants, aligning with regulatory requirements for reduced chemical pollution.

Key Differences in Chemical Composition

Biodegradable coolants primarily consist of natural esters and organic additives that break down easily in the environment, reducing toxicity and landfill impact. Conventional coolants contain ethylene glycol or propylene glycol combined with corrosion inhibitors and additives that provide longer-lasting thermal protection but are less environmentally friendly. The chemical composition of biodegradable coolants emphasizes eco-safety and biodegradability, while conventional coolants prioritize performance and longevity under high-temperature conditions.

Environmental Impact: Biodegradable vs. Conventional Coolants

Biodegradable coolants significantly reduce environmental pollution by breaking down naturally without releasing toxic substances, unlike conventional coolants that often contain harmful chemicals such as ethylene glycol and heavy metals. These traditional coolants pose risks of soil and water contamination, leading to adverse effects on wildlife and ecosystems. Choosing biodegradable coolants supports sustainable automotive practices by minimizing ecological damage and promoting safer disposal methods.

Performance and Efficiency Comparisons

Biodegradable coolants demonstrate comparable thermal conductivity and heat transfer efficiency to conventional coolants, ensuring effective engine temperature regulation. Their enhanced chemical stability reduces corrosion and deposit formation, prolonging radiator and water pump lifespan. Despite slightly higher initial costs, biodegradable coolants offer improved environmental benefits without compromising vehicle performance or fuel efficiency.

Compatibility with Automotive Engines

Biodegradable coolants are formulated with environmentally friendly additives that maintain compatibility with various automotive engine materials, such as aluminum, rubber, and plastic components, reducing the risk of corrosion and degradation. Conventional coolants often contain ethylene glycol and traditional corrosion inhibitors, which provide proven protection but may pose higher environmental hazards if leaked. Engine manufacturers increasingly recognize biodegradable coolants as suitable alternatives that align with modern emission standards without compromising engine performance and longevity.

Longevity and Maintenance Requirements

Biodegradable coolants typically have a shorter lifespan compared to conventional coolants due to their natural additive composition, requiring more frequent replacement to maintain optimal engine performance. Conventional coolants generally offer extended durability with corrosion inhibitors that prolong cooling system integrity, reducing maintenance intervals and costs. Proper monitoring and timely coolant changes are essential for both types to ensure effective heat dissipation and prevent engine overheating.

Cost Analysis: Initial and Long-term Considerations

Biodegradable coolants typically have a higher initial cost compared to conventional coolants due to eco-friendly ingredients and specialized formulation. Long-term considerations reveal potential savings through reduced environmental compliance fees, lower disposal costs, and extended equipment lifespan. Conventional coolants may offer upfront affordability but incur higher expenses from environmental fines and waste management over time.

Safety Measures and Handling Procedures

Biodegradable coolants offer enhanced safety benefits due to their non-toxic, environmentally friendly composition, significantly reducing hazardous exposure risks during handling and disposal compared to conventional coolants containing ethylene glycol or propylene glycol. Proper handling procedures for biodegradable coolants emphasize the use of standard personal protective equipment (PPE) and adherence to spill containment protocols, while conventional coolants require more rigorous management to prevent skin irritation, ingestion hazards, and environmental contamination. Compliance with regulatory guidelines such as OSHA and EPA standards is critical for both types, but biodegradable coolants simplify safety measures by minimizing toxic waste and ecological impact.

Regulatory Standards and Compliance

Biodegradable coolants comply with stringent regulatory standards such as REACH and EPA guidelines, ensuring reduced environmental impact through lower toxicity and enhanced biodegradability. Conventional coolants often face stricter limitations due to harmful chemicals like ethylene glycol, which are subject to rigorous disposal and handling regulations. Automotive manufacturers increasingly prefer biodegradable coolants to meet evolving global emissions standards and promote sustainability in vehicle maintenance.

Future Trends in Automotive Coolants

Future trends in automotive coolants emphasize the shift towards biodegradable formulations to reduce environmental impact and improve sustainability. Advanced biodegradable coolants utilize plant-based additives and non-toxic corrosion inhibitors, offering comparable thermal performance to conventional ethylene glycol-based coolants while enhancing eco-friendliness. Research continues to focus on optimizing biodegradability, freeze protection, and heat transfer properties to meet stricter emissions regulations and green vehicle manufacturing standards.

biodegradable coolant vs conventional coolant Infographic

difterm.com

difterm.com