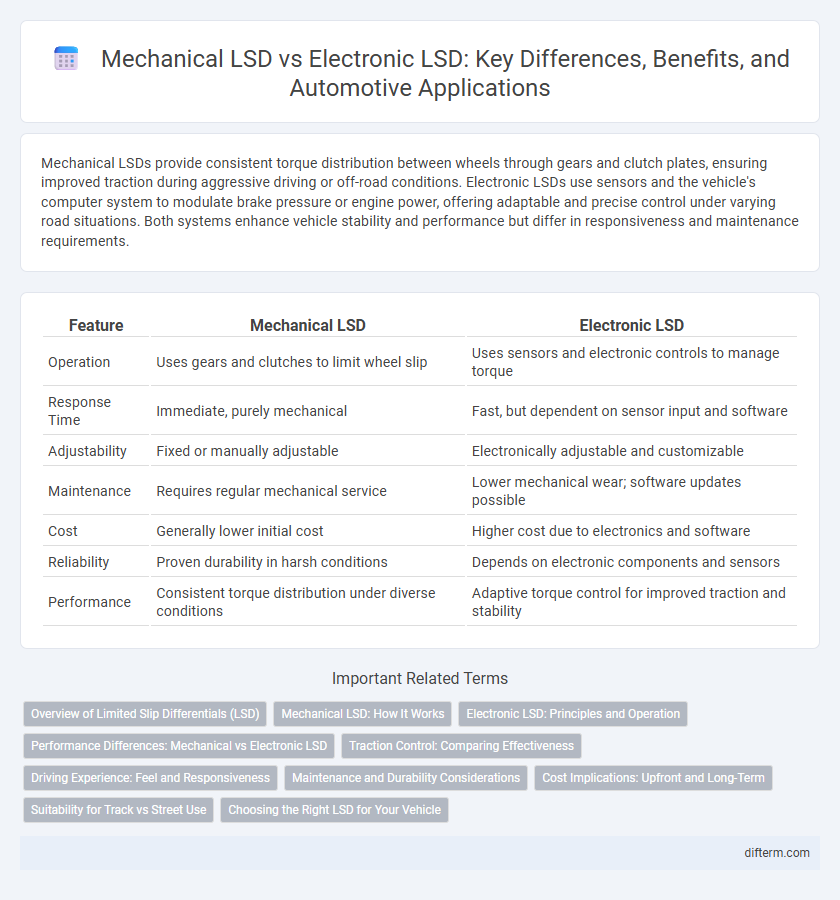

Mechanical LSDs provide consistent torque distribution between wheels through gears and clutch plates, ensuring improved traction during aggressive driving or off-road conditions. Electronic LSDs use sensors and the vehicle's computer system to modulate brake pressure or engine power, offering adaptable and precise control under varying road situations. Both systems enhance vehicle stability and performance but differ in responsiveness and maintenance requirements.

Table of Comparison

| Feature | Mechanical LSD | Electronic LSD |

|---|---|---|

| Operation | Uses gears and clutches to limit wheel slip | Uses sensors and electronic controls to manage torque |

| Response Time | Immediate, purely mechanical | Fast, but dependent on sensor input and software |

| Adjustability | Fixed or manually adjustable | Electronically adjustable and customizable |

| Maintenance | Requires regular mechanical service | Lower mechanical wear; software updates possible |

| Cost | Generally lower initial cost | Higher cost due to electronics and software |

| Reliability | Proven durability in harsh conditions | Depends on electronic components and sensors |

| Performance | Consistent torque distribution under diverse conditions | Adaptive torque control for improved traction and stability |

Overview of Limited Slip Differentials (LSD)

Limited Slip Differentials (LSD) are crucial in automotive drivetrains for improving traction by distributing torque between wheels while allowing some difference in wheel speed. Mechanical LSDs use physical components like clutch packs, gears, or cones to limit wheel slip through direct torque transfer, offering durability and predictable performance in aggressive driving conditions. Electronic LSDs employ sensors and actuators to modulate torque distribution actively, providing adaptive control for enhanced stability and traction under varying driving environments.

Mechanical LSD: How It Works

Mechanical Limited Slip Differentials (LSDs) function through a system of clutch plates or gears that distribute torque between the wheels based on traction demands. When one wheel begins to slip, the mechanical LSD transfers torque to the wheel with more grip, enhancing stability and cornering performance. This purely mechanical operation requires no electronic intervention, providing reliable, immediate torque distribution in various driving conditions.

Electronic LSD: Principles and Operation

Electronic LSD (Limited Slip Differential) enhances vehicle traction by using sensors and an electronic control unit (ECU) to monitor wheel speed and torque distribution. It operates by selectively applying braking force to slipping wheels and redistributing torque to wheels with better grip, improving stability and handling without the mechanical wear associated with traditional LSDs. This system integrates seamlessly with traction control and stability programs, providing dynamic and precise torque vectoring for optimal performance in various driving conditions.

Performance Differences: Mechanical vs Electronic LSD

Mechanical LSDs offer consistent torque distribution through physical gear engagement, providing reliable performance in high-demand driving conditions such as track racing or off-road environments. Electronic LSDs utilize sensors and computer-controlled clutches to modulate torque dynamically, enhancing traction adaptability and reducing wheel slip during varying road surfaces. Performance differences primarily hinge on mechanical LSD's predictability and durability versus electronic LSD's precision and responsiveness in real-time driving scenarios.

Traction Control: Comparing Effectiveness

Mechanical LSD provides consistent traction control by physically distributing torque between wheels, enhancing grip during cornering without electronic intervention. Electronic LSD uses sensors and the vehicle's ECU to modulate torque distribution dynamically, offering adaptive traction control that responds to varying road conditions more precisely. Comparing effectiveness, mechanical LSD delivers reliable mechanical resistance, while electronic LSD excels in customizable traction management and integration with stability control systems.

Driving Experience: Feel and Responsiveness

Mechanical LSDs deliver a more direct, tactile driving experience by using gears and clutch plates that mechanically distribute torque, offering immediate feedback and enhanced traction during aggressive cornering. Electronic LSDs use sensors and actuators to modulate torque, providing smoother, adaptive responses that improve stability and control under varying road conditions. Drivers seeking raw mechanical engagement prefer Mechanical LSDs, while Electronic LSDs appeal to those prioritizing seamless, customizable handling.

Maintenance and Durability Considerations

Mechanical LSDs require regular inspection of the clutch packs and gears, with maintenance intervals typically including fluid changes and wear assessments to ensure optimal performance. Electronic LSDs feature fewer mechanical components, reducing physical wear and often resulting in lower maintenance demands, but their reliance on sensors and electronic control units makes them susceptible to software faults and electronic failures. Durability for mechanical LSDs is generally robust under high-stress conditions, while electronic LSD lifespan depends heavily on the vehicle's overall electrical system health and software updates.

Cost Implications: Upfront and Long-Term

Mechanical LSDs typically have lower upfront costs due to simpler design and fewer electronic components, making them more budget-friendly for initial installation. Electronic LSDs, while more expensive initially because of advanced sensors and control units, offer enhanced performance and adaptability that can reduce long-term maintenance expenses. Over time, mechanical LSDs may incur higher wear-related repair costs, whereas electronic LSDs can benefit from software updates and diagnostics that optimize longevity and reliability.

Suitability for Track vs Street Use

Mechanical LSDs offer consistent torque distribution and durability ideal for aggressive track conditions and high-performance driving, providing reliable traction during rapid acceleration and cornering. Electronic LSDs deliver adaptive, sensor-driven torque control, enhancing stability and comfort for everyday street use by adjusting to variable road conditions and driver inputs. Track enthusiasts benefit from the mechanical LSD's predictable engagement, while street drivers prefer the electronic LSD's seamless modulation and safety features.

Choosing the Right LSD for Your Vehicle

Mechanical LSDs provide consistent torque distribution through internal clutches or gears, offering reliable performance in high-stress driving conditions and durability suited for off-road and racing applications. Electronic LSDs use sensors and actuators to dynamically adjust torque based on driving conditions, enhancing traction and stability with greater precision and adaptability for street and all-weather driving. Selecting the right LSD depends on your driving style and vehicle use, where mechanical units excel in aggressive, performance-focused settings, while electronic LSDs optimize everyday handling and safety.

Mechanical LSD vs Electronic LSD Infographic

difterm.com

difterm.com