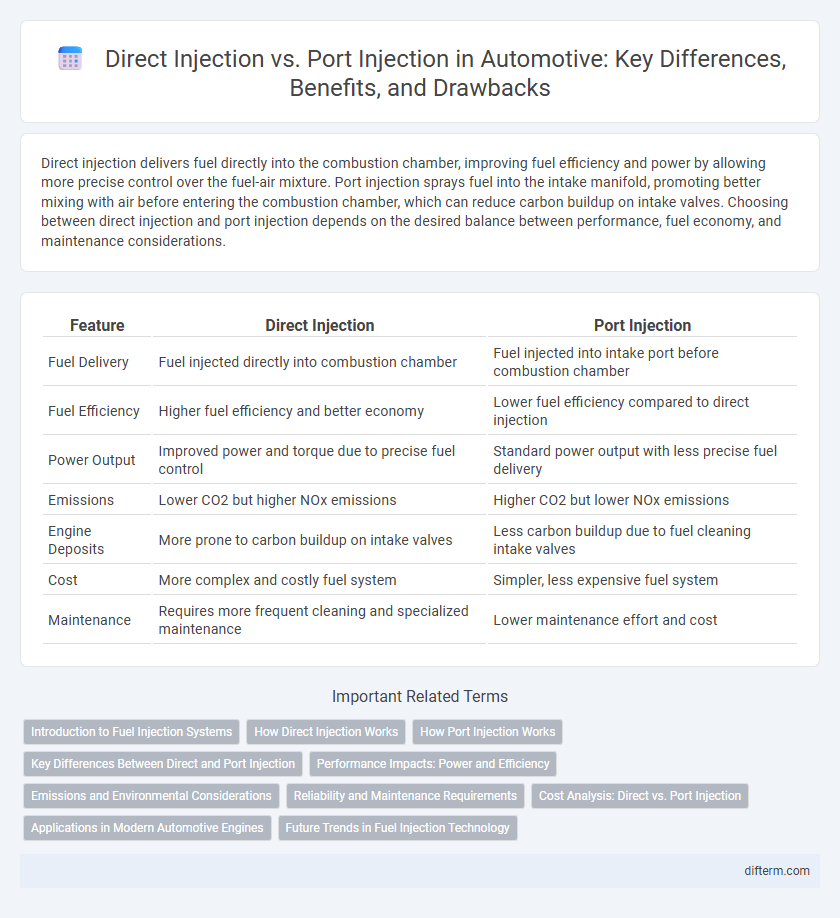

Direct injection delivers fuel directly into the combustion chamber, improving fuel efficiency and power by allowing more precise control over the fuel-air mixture. Port injection sprays fuel into the intake manifold, promoting better mixing with air before entering the combustion chamber, which can reduce carbon buildup on intake valves. Choosing between direct injection and port injection depends on the desired balance between performance, fuel economy, and maintenance considerations.

Table of Comparison

| Feature | Direct Injection | Port Injection |

|---|---|---|

| Fuel Delivery | Fuel injected directly into combustion chamber | Fuel injected into intake port before combustion chamber |

| Fuel Efficiency | Higher fuel efficiency and better economy | Lower fuel efficiency compared to direct injection |

| Power Output | Improved power and torque due to precise fuel control | Standard power output with less precise fuel delivery |

| Emissions | Lower CO2 but higher NOx emissions | Higher CO2 but lower NOx emissions |

| Engine Deposits | More prone to carbon buildup on intake valves | Less carbon buildup due to fuel cleaning intake valves |

| Cost | More complex and costly fuel system | Simpler, less expensive fuel system |

| Maintenance | Requires more frequent cleaning and specialized maintenance | Lower maintenance effort and cost |

Introduction to Fuel Injection Systems

Fuel injection systems in automotive engines primarily include direct injection and port injection, each delivering fuel differently to optimize combustion efficiency. Direct injection sprays fuel directly into the combustion chamber, allowing for precise fuel control and improved power output, while port injection injects fuel into the intake manifold, promoting better air-fuel mixing and cleaner emissions. Understanding the distinctions between direct and port injection is crucial for evaluating engine performance, fuel economy, and emission control technologies.

How Direct Injection Works

Direct injection delivers fuel directly into the combustion chamber at high pressure, enabling precise control over the fuel-air mixture and improving combustion efficiency. This method promotes better atomization of fuel, which enhances power output and reduces emissions compared to port injection. By injecting fuel directly, the engine achieves faster response times and increased fuel economy under various operating conditions.

How Port Injection Works

Port injection delivers fuel directly into the intake manifold just before the intake valve, allowing precise fuel-air mixing for improved combustion efficiency. This method ensures better fuel atomization and distribution compared to direct injection, reducing the risk of carbon buildup on intake valves. Port injection systems are often combined with direct injection in modern engines to optimize fuel economy and emissions control.

Key Differences Between Direct and Port Injection

Direct injection delivers fuel directly into the combustion chamber, enabling precise fuel control and improved combustion efficiency, which results in better power output and fuel economy. Port injection sprays fuel into the intake manifold, promoting better air-fuel mixing and reducing carbon buildup on intake valves, enhancing engine durability. Key differences include fuel atomization location, impact on emissions, and effects on engine cooling and knock resistance.

Performance Impacts: Power and Efficiency

Direct injection improves power output by delivering fuel directly into the combustion chamber, promoting a more precise air-fuel mixture and enhanced combustion efficiency. Port injection enhances fuel atomization by injecting fuel into the intake ports, which can improve throttle response and reduce carbon buildup on intake valves. Combining both systems in dual injection engines maximizes combustion control, leading to superior power delivery and fuel efficiency in modern automotive applications.

Emissions and Environmental Considerations

Direct injection engines offer improved fuel atomization and combustion efficiency, resulting in lower carbon dioxide (CO2) emissions compared to port injection systems. However, direct injection tends to produce higher particulate matter (PM) and nitrogen oxides (NOx) emissions, necessitating advanced after-treatment technologies such as gasoline particulate filters (GPFs) and selective catalytic reduction (SCR) systems. Port injection engines typically emit fewer particulates but have higher overall fuel consumption, leading to increased greenhouse gas output relative to optimized direct injection setups.

Reliability and Maintenance Requirements

Direct injection systems offer improved fuel efficiency and power but tend to accumulate carbon deposits on intake valves, increasing maintenance frequency compared to port injection. Port injection injects fuel into the intake manifold, providing cleaner intake valves and generally greater reliability with less frequent maintenance. Despite higher maintenance demands, modern direct injection engines often incorporate dual injection systems to mitigate reliability concerns and balance performance benefits.

Cost Analysis: Direct vs. Port Injection

Direct injection systems generally incur higher initial costs due to advanced fuel injectors and high-pressure fuel pumps required for precise fuel delivery. Port injection systems offer lower manufacturing and maintenance expenses, benefiting from simpler components and less stringent fuel quality requirements. Long-term cost analysis must also consider fuel efficiency gains and emission compliance associated with direct injection technology.

Applications in Modern Automotive Engines

Direct injection systems deliver fuel directly into the combustion chamber, enabling precise control over fuel atomization and combustion timing, which enhances power output and fuel efficiency in modern turbocharged and high-performance engines. Port injection sprays fuel into the intake ports, mixing with air before entering the combustion chamber, offering improved fuel-air mixing and lower particulate emissions, commonly used in naturally aspirated engines and hybrid powertrains. Automakers often combine direct and port injection technologies in dual injection systems to optimize performance, reduce engine knocking, and meet stringent emission standards across various driving conditions.

Future Trends in Fuel Injection Technology

Future trends in fuel injection technology emphasize the integration of advanced direct injection systems with improved spray atomization and multiple injection events to enhance combustion efficiency and reduce emissions. Emerging port injection designs incorporate variable injection timing and optimized injector placement to balance power output and fuel economy, especially in hybrid and flex-fuel vehicles. Innovations in fuel injection continue to focus on precise fuel delivery control using AI-driven engine management systems and adaptive sensors to meet stricter environmental regulations and evolving consumer demands.

direct injection vs port injection Infographic

difterm.com

difterm.com