Bushings and bearings both serve as components that reduce friction between moving parts in automotive applications, but they differ significantly in design and function. Bushings are simple, cylindrical sleeves made from materials like rubber or metal, providing basic support and vibration isolation without rolling elements, which makes them ideal for controlling noise and wear in suspension systems. Bearings contain rolling elements such as balls or rollers, allowing for smoother rotation and handling higher loads with less friction, making them essential for wheel hubs and precise engine components.

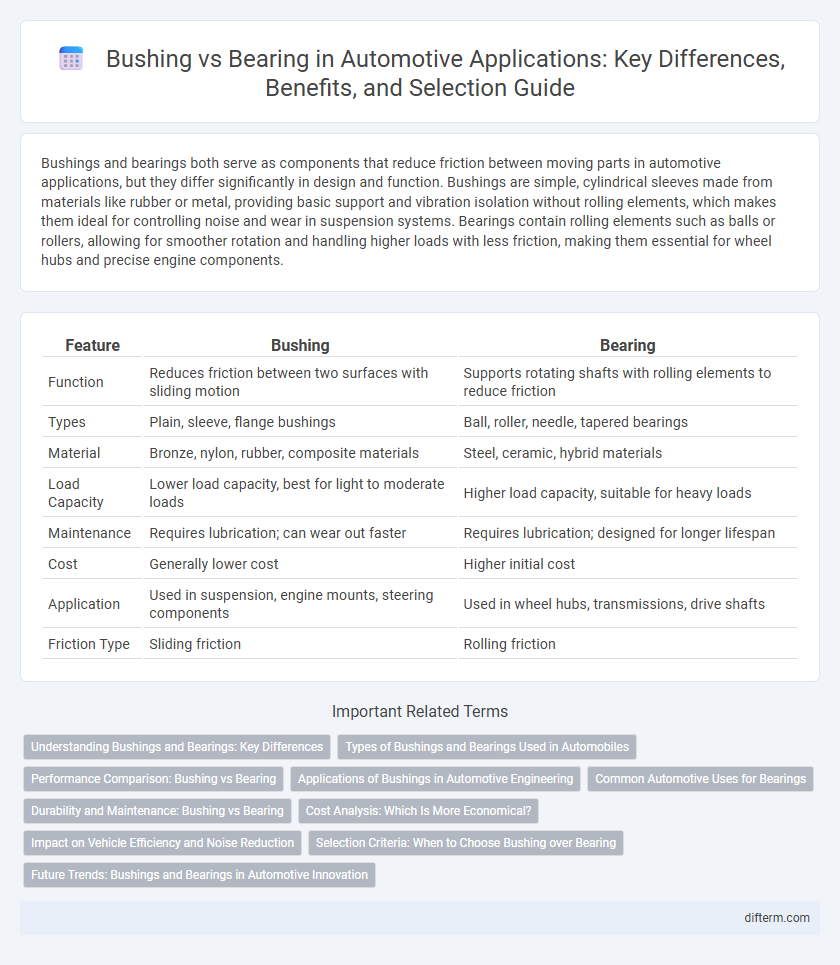

Table of Comparison

| Feature | Bushing | Bearing |

|---|---|---|

| Function | Reduces friction between two surfaces with sliding motion | Supports rotating shafts with rolling elements to reduce friction |

| Types | Plain, sleeve, flange bushings | Ball, roller, needle, tapered bearings |

| Material | Bronze, nylon, rubber, composite materials | Steel, ceramic, hybrid materials |

| Load Capacity | Lower load capacity, best for light to moderate loads | Higher load capacity, suitable for heavy loads |

| Maintenance | Requires lubrication; can wear out faster | Requires lubrication; designed for longer lifespan |

| Cost | Generally lower cost | Higher initial cost |

| Application | Used in suspension, engine mounts, steering components | Used in wheel hubs, transmissions, drive shafts |

| Friction Type | Sliding friction | Rolling friction |

Understanding Bushings and Bearings: Key Differences

Bushings and bearings both serve to reduce friction and wear in automotive applications, but bushings are typically simpler, made from materials like bronze or plastic, and provide sliding motion support without moving parts. Bearings, on the other hand, contain rolling elements such as balls or rollers, allowing for smoother rotation and higher load capacity in components like wheel hubs or transmissions. Selecting between bushings and bearings depends on factors such as load type, speed, maintenance requirements, and cost efficiency in vehicle systems.

Types of Bushings and Bearings Used in Automobiles

Automobiles utilize various types of bushings such as rubber, polyurethane, and bronze, each designed to reduce vibration, absorb shocks, and provide flexibility in suspension and steering systems. Bearings commonly used include ball bearings, roller bearings, and tapered bearings, engineered to support rotating parts, minimize friction, and handle both radial and axial loads in wheels, engines, and transmissions. The selection of bushings and bearings directly influences vehicle performance, durability, and ride comfort.

Performance Comparison: Bushing vs Bearing

Bearings provide superior performance over bushings in automotive applications due to lower friction and higher load capacity, enhancing overall efficiency and durability. Bushings, while simpler and cost-effective, exhibit higher wear rates and limited speed tolerance, making them suitable primarily for low-speed, low-load conditions. Selecting bearings improves vehicle responsiveness and longevity, particularly in high-stress components such as suspension and steering systems.

Applications of Bushings in Automotive Engineering

Bushings in automotive engineering serve as cost-effective solutions for reducing friction and wear in suspension systems, steering components, and engine mounts. Their ability to absorb vibrations and accommodate misalignment makes them ideal for applications requiring noise reduction and improved ride comfort. Unlike bearings, bushings provide durable, low-maintenance performance in load-bearing joints subjected to oscillating or sliding motion.

Common Automotive Uses for Bearings

Bearings in automotive applications are primarily used in wheel hubs, transmissions, and engine components to reduce friction and support rotational motion under varying loads. Common types include ball bearings, roller bearings, and needle bearings, each selected for specific performance criteria such as load capacity and speed. These components enhance vehicle efficiency, durability, and safety by ensuring smooth and reliable operation of moving parts.

Durability and Maintenance: Bushing vs Bearing

Bushings offer superior durability in harsh environments due to their ability to absorb shock and resist contamination without requiring frequent lubrication. Bearings generally provide smoother operation but demand regular maintenance and lubrication to prevent wear and extend service life. In automotive applications, choosing bushings enhances longevity with lower maintenance costs, while bearings prioritize precision and reduced friction at the expense of more intensive upkeep.

Cost Analysis: Which Is More Economical?

Bushings generally offer a more economical solution than bearings due to lower manufacturing costs and simpler design, making them ideal for low-speed or light-load automotive applications. Bearings, while typically more expensive upfront, provide superior performance and longevity under high-speed or heavy-load conditions, potentially reducing long-term maintenance expenses. Analyzing total cost of ownership reveals that bushings are cost-effective for budget-sensitive automotive projects, whereas bearings justify their higher price through enhanced durability and reliability in critical components.

Impact on Vehicle Efficiency and Noise Reduction

Bushings significantly enhance vehicle efficiency by reducing friction and wear between moving parts, leading to lower energy consumption and prolonged component life. Bearings offer superior noise reduction due to their precision design and ability to maintain consistent alignment under dynamic loads, minimizing vibrations and operational noise. Selecting the appropriate component directly influences fuel economy and passenger comfort by optimizing mechanical performance and dampening sound emissions.

Selection Criteria: When to Choose Bushing over Bearing

Bushing is preferred over bearing in applications requiring simple design, cost-effectiveness, and low-speed or oscillating motion due to its low maintenance and ability to withstand contamination. Bushings offer superior performance in environments with limited space or where noise reduction is critical, making them ideal for automotive suspension components and steering systems. Selection criteria favor bushings when durability and load distribution are prioritized over rotational speed and precision alignment.

Future Trends: Bushings and Bearings in Automotive Innovation

Future trends in automotive innovation indicate a growing shift towards advanced composite bushings and hybrid ceramic bearings, enhancing durability and reducing vehicle weight. Smart materials integrated with sensors within bushings and bearings are improving predictive maintenance and real-time performance monitoring. Electrification and autonomous vehicle technologies drive the demand for components with higher efficiency, lower friction, and extended service life.

bushing vs bearing Infographic

difterm.com

difterm.com