Stock Keeping Unit (SKU) is an internal alphanumeric code used by retail pet stores to track inventory and manage stock levels, tailored specifically to their product range. Universal Product Code (UPC) is a standardized barcode found on pet products, enabling quick scanning at checkout and facilitating supplier and retailer communication. SKUs offer customization for inventory control, while UPCs ensure consistency and efficiency across the entire supply chain.

Table of Comparison

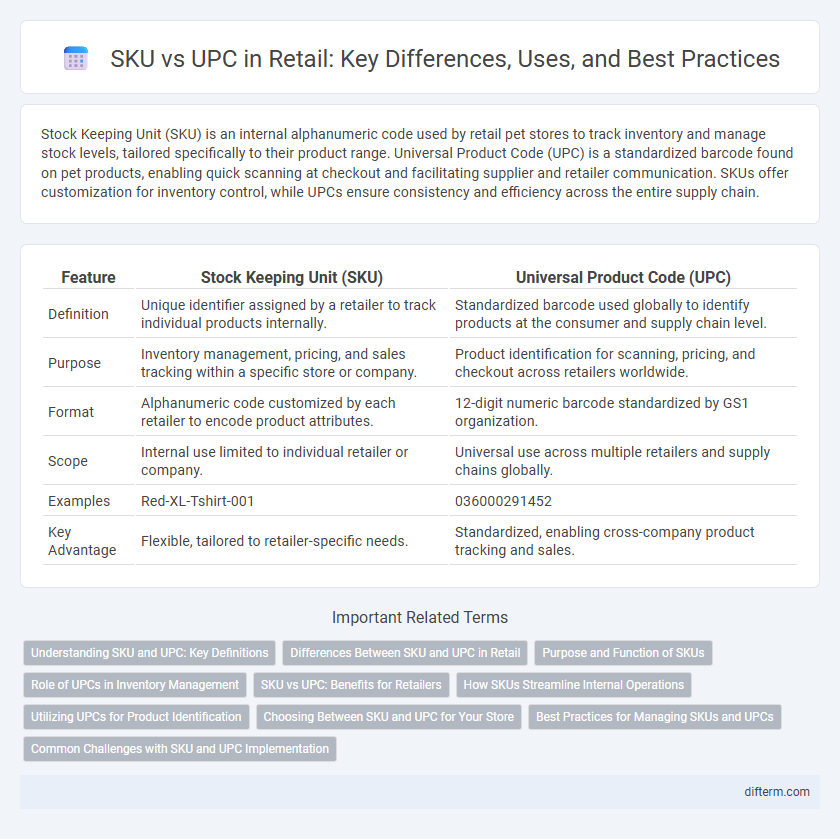

| Feature | Stock Keeping Unit (SKU) | Universal Product Code (UPC) |

|---|---|---|

| Definition | Unique identifier assigned by a retailer to track individual products internally. | Standardized barcode used globally to identify products at the consumer and supply chain level. |

| Purpose | Inventory management, pricing, and sales tracking within a specific store or company. | Product identification for scanning, pricing, and checkout across retailers worldwide. |

| Format | Alphanumeric code customized by each retailer to encode product attributes. | 12-digit numeric barcode standardized by GS1 organization. |

| Scope | Internal use limited to individual retailer or company. | Universal use across multiple retailers and supply chains globally. |

| Examples | Red-XL-Tshirt-001 | 036000291452 |

| Key Advantage | Flexible, tailored to retailer-specific needs. | Standardized, enabling cross-company product tracking and sales. |

Understanding SKU and UPC: Key Definitions

Stock Keeping Unit (SKU) is a unique alphanumeric code used by retailers to identify and track inventory at the product level, often customized for internal management. Universal Product Code (UPC) is a standardized barcode symbology consisting of 12 numeric digits, designed to be scanned at point of sale for product identification across retail environments. While SKUs facilitate internal inventory control, UPCs enable universal product recognition and streamline checkout processes globally.

Differences Between SKU and UPC in Retail

Stock Keeping Unit (SKU) is a unique alphanumeric code assigned by retailers to identify and track individual products within their inventory, focusing on internal management and specific product attributes like size or color. Universal Product Code (UPC) is a standardized barcode symbology used globally to uniquely identify products at the point of sale, facilitating cross-retailer recognition and efficient checkout processing. While SKUs are retailer-specific and customizable, UPCs are manufacturer-assigned and consistent across all retailers, making UPCs essential for universal product identification and SKUs critical for detailed inventory control.

Purpose and Function of SKUs

Stock Keeping Units (SKUs) serve as unique alphanumeric identifiers created by retailers to track inventory internally, enabling precise management of product variations such as size, color, and style within a store. Unlike Universal Product Codes (UPCs), which are standardized barcodes used mainly for point-of-sale scanning and universal identification of products across retailers, SKUs focus on optimizing inventory control, pricing strategies, and sales analysis specific to each retailer's system. The purpose of SKUs is to facilitate efficient stock management, reorder accuracy, and detailed reporting tailored to a retailer's operational needs.

Role of UPCs in Inventory Management

Universal Product Codes (UPCs) serve as essential identifiers in retail inventory management by enabling efficient product scanning and real-time stock tracking at the point of sale. UPCs facilitate streamlined replenishment processes by providing accurate sales data that helps predict inventory needs and reduce stockouts. Their standardized format supports seamless integration across supply chains, improving accuracy in demand forecasting and inventory control.

SKU vs UPC: Benefits for Retailers

SKUs provide retailers with detailed, customizable tracking of inventory specific to store needs, improving stock management accuracy and sales analysis. UPCs offer standardized product identification across suppliers and retail chains, facilitating efficient checkout and supply chain integration. Leveraging both SKUs and UPCs enhances inventory control, reduces errors, and optimizes overall retail operations.

How SKUs Streamline Internal Operations

Stock Keeping Units (SKUs) are unique alphanumeric codes assigned internally by retailers to track inventory, manage stock levels, and facilitate efficient order fulfillment, enabling precise control over product variations such as size, color, and style. Unlike Universal Product Codes (UPCs), which are standardized barcodes used for external identification and sales scanning, SKUs provide retailers with detailed insights into sales trends and inventory movements specific to their store or chain. This internal optimization reduces stockouts, improves replenishment accuracy, and enhances overall supply chain efficiency within retail operations.

Utilizing UPCs for Product Identification

Utilizing Universal Product Codes (UPCs) for product identification enables retailers to streamline inventory management and enhance checkout efficiency by providing a unique, standardized barcode for each product. Unlike Stock Keeping Units (SKUs), which are internally generated and vary between retailers, UPCs are globally recognized and facilitate accurate tracking across supply chains and retail platforms. Implementing UPCs improves data accuracy, reduces errors in sales transactions, and supports seamless integration with digital inventory systems and point-of-sale technologies.

Choosing Between SKU and UPC for Your Store

Selecting between a Stock Keeping Unit (SKU) and a Universal Product Code (UPC) depends on the retail store's inventory management needs and scale. SKUs are unique alphanumeric codes created internally to track products at a granular level, offering detailed organization tailored to specific store operations. UPCs are standardized barcodes used globally for product identification and are essential for sales tracking and supply chain management across multiple retailers.

Best Practices for Managing SKUs and UPCs

Effective management of Stock Keeping Units (SKUs) and Universal Product Codes (UPCs) enhances inventory accuracy and sales tracking in retail. Best practices include assigning unique SKUs tailored to internal inventory needs while ensuring each product's UPC remains standardized for external scanning and supply chain efficiency. Regular audits and integration of SKU and UPC data into centralized inventory management systems enable seamless tracking and reduce errors in stock replenishment.

Common Challenges with SKU and UPC Implementation

Common challenges with SKU and UPC implementation in retail include inconsistencies in SKU assignment leading to inventory errors and difficulties in tracking product variations. UPC scanning errors and mismatches often result from damaged barcodes or incorrect database entries, causing delays at checkout and discrepancies in sales data. Efficient synchronization between SKU systems and UPC databases is critical to maintaining accurate inventory management and seamless retail operations.

Stock Keeping Unit (SKU) vs Universal Product Code (UPC) Infographic

difterm.com

difterm.com