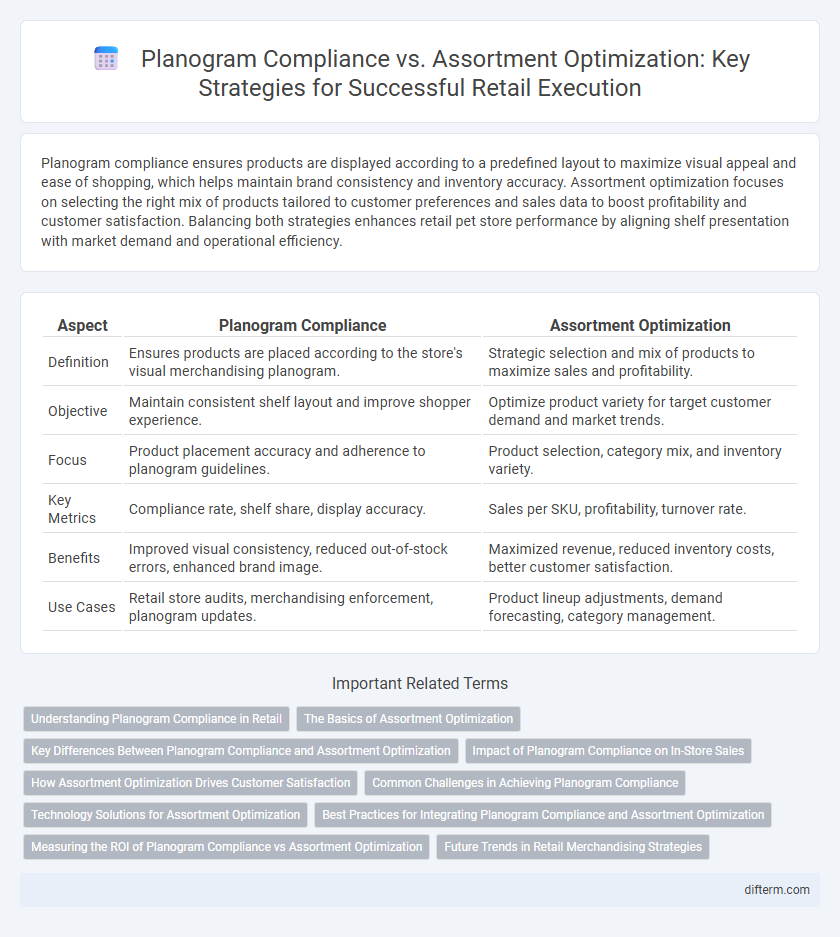

Planogram compliance ensures products are displayed according to a predefined layout to maximize visual appeal and ease of shopping, which helps maintain brand consistency and inventory accuracy. Assortment optimization focuses on selecting the right mix of products tailored to customer preferences and sales data to boost profitability and customer satisfaction. Balancing both strategies enhances retail pet store performance by aligning shelf presentation with market demand and operational efficiency.

Table of Comparison

| Aspect | Planogram Compliance | Assortment Optimization |

|---|---|---|

| Definition | Ensures products are placed according to the store's visual merchandising planogram. | Strategic selection and mix of products to maximize sales and profitability. |

| Objective | Maintain consistent shelf layout and improve shopper experience. | Optimize product variety for target customer demand and market trends. |

| Focus | Product placement accuracy and adherence to planogram guidelines. | Product selection, category mix, and inventory variety. |

| Key Metrics | Compliance rate, shelf share, display accuracy. | Sales per SKU, profitability, turnover rate. |

| Benefits | Improved visual consistency, reduced out-of-stock errors, enhanced brand image. | Maximized revenue, reduced inventory costs, better customer satisfaction. |

| Use Cases | Retail store audits, merchandising enforcement, planogram updates. | Product lineup adjustments, demand forecasting, category management. |

Understanding Planogram Compliance in Retail

Planogram compliance in retail ensures that products are displayed according to the designed layout, maximizing shelf space efficiency and enhancing customer experience. Accurate planogram adherence drives increased sales by making popular and high-margin items more visible and accessible. Monitoring compliance enables retailers to identify gaps and adjust assortments strategically for optimal inventory management and competitive advantage.

The Basics of Assortment Optimization

Assortment optimization involves strategically selecting the right mix of products to meet consumer demand, maximize sales, and improve inventory turnover, while planogram compliance ensures that these products are displayed according to predefined layouts for consistency and brand standards. Effective assortment optimization uses data analytics and customer insights to determine the optimal product variety and depth, enhancing shelf productivity and reducing stockouts. Understanding the basics of assortment optimization is crucial for retailers aiming to balance product availability with planogram execution to drive profitability and customer satisfaction.

Key Differences Between Planogram Compliance and Assortment Optimization

Planogram compliance ensures that retail shelves precisely match predetermined layouts, maximizing shelf space utilization and enhancing visual merchandising consistency. Assortment optimization focuses on selecting the right mix and variety of products to meet customer demand and improve sales performance. The key difference lies in planogram compliance maintaining display accuracy, while assortment optimization centers on strategic product selection for maximizing profitability.

Impact of Planogram Compliance on In-Store Sales

Planogram compliance significantly impacts in-store sales by ensuring optimal product placement and maximizing shelf visibility, which drives customer purchases and enhances shopping experience. Retailers who maintain over 90% planogram compliance see up to a 15% increase in sales due to improved product accessibility and reduced stockouts. Consistent adherence to planograms also supports assortment optimization by aligning product variety with consumer demand, ultimately boosting overall store performance.

How Assortment Optimization Drives Customer Satisfaction

Assortment optimization enhances customer satisfaction by strategically selecting products that meet consumer preferences and demand patterns, ensuring availability of desired items. This targeted assortment increases shopper engagement and reduces stockouts, leading to a more seamless shopping experience. In contrast, planogram compliance focuses on the precise placement of products, but without optimized assortment, it cannot fully address customer needs or boost satisfaction levels.

Common Challenges in Achieving Planogram Compliance

Achieving planogram compliance faces common challenges such as inconsistent shelf placement, frequent stockouts, and inaccurate inventory levels that hinder optimal product visibility and customer experience. Retailers often struggle with real-time monitoring and enforcement across multiple locations, complicating adherence to planogram guidelines. Variability in store layouts and employee training also impact the consistency needed for successful planogram execution.

Technology Solutions for Assortment Optimization

Technology solutions for assortment optimization utilize advanced analytics and AI-driven algorithms to dynamically adjust product mixes based on real-time consumer demand, shelf space availability, and sales data. These tools enhance planogram compliance by enabling retailers to implement data-backed decisions that maximize shelf efficiency and product visibility. Integrating machine learning models with inventory management systems ensures optimal stock levels and tailored assortments that improve customer satisfaction and drive revenue growth.

Best Practices for Integrating Planogram Compliance and Assortment Optimization

Achieving seamless integration of planogram compliance and assortment optimization requires leveraging real-time sales data and consumer behavior insights to align inventory with store layouts accurately. Employing advanced analytics and AI-driven software enhances decision-making, ensuring product placements maximize visibility and cater to local demand variations. Regular audits combined with adaptive planogram adjustments foster consistent compliance, driving improved shelf performance and increased revenue in retail environments.

Measuring the ROI of Planogram Compliance vs Assortment Optimization

Measuring the ROI of planogram compliance involves analyzing sales lift, inventory turnover, and shelf space efficiency to ensure products are displayed as intended, driving consumer purchase behavior. In contrast, assortment optimization focuses on maximizing product mix profitability by balancing variety and consumer demand, using data analytics to identify top-performing SKUs and reduce stockouts or overstock. Comparing these metrics reveals that while planogram compliance improves in-store execution and brand consistency, assortment optimization directly enhances revenue by aligning inventory with customer preferences.

Future Trends in Retail Merchandising Strategies

Planogram compliance ensures product placement aligns with retailer standards, maximizing shelf efficiency and customer experience, while assortment optimization leverages data analytics to tailor product mix based on consumer demand and sales patterns. Future trends in retail merchandising increasingly integrate AI-driven technologies to dynamically adjust planograms in real-time, enhancing both compliance and assortment precision. The synergy between these approaches, supported by machine learning and IoT, drives higher sales conversion and inventory turnover in omnichannel retail environments.

Planogram Compliance vs Assortment Optimization Infographic

difterm.com

difterm.com