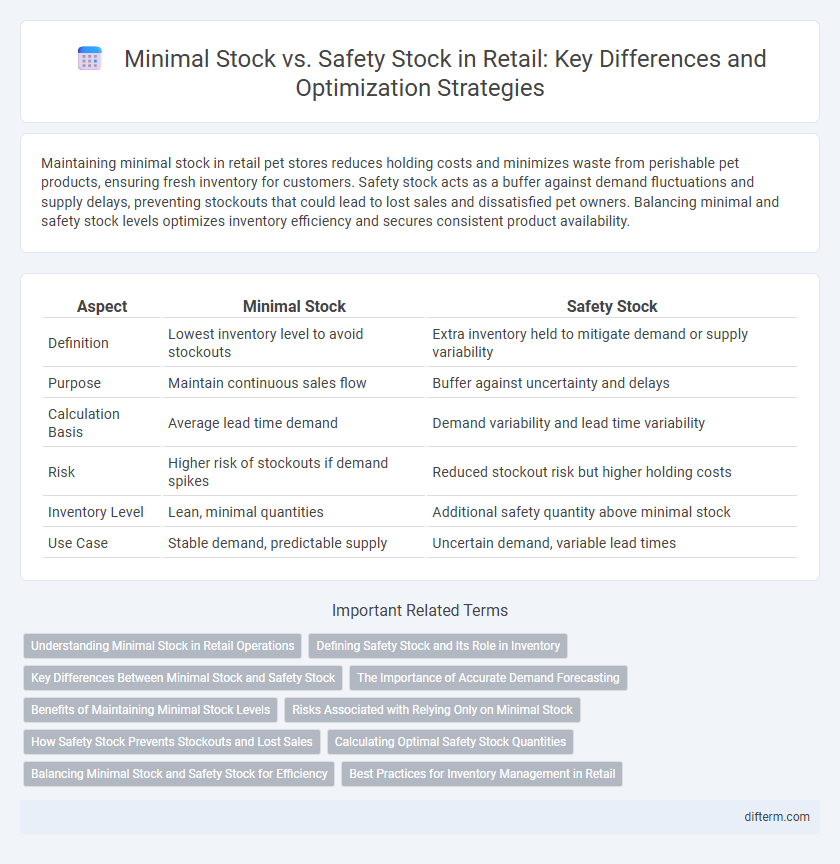

Maintaining minimal stock in retail pet stores reduces holding costs and minimizes waste from perishable pet products, ensuring fresh inventory for customers. Safety stock acts as a buffer against demand fluctuations and supply delays, preventing stockouts that could lead to lost sales and dissatisfied pet owners. Balancing minimal and safety stock levels optimizes inventory efficiency and secures consistent product availability.

Table of Comparison

| Aspect | Minimal Stock | Safety Stock |

|---|---|---|

| Definition | Lowest inventory level to avoid stockouts | Extra inventory held to mitigate demand or supply variability |

| Purpose | Maintain continuous sales flow | Buffer against uncertainty and delays |

| Calculation Basis | Average lead time demand | Demand variability and lead time variability |

| Risk | Higher risk of stockouts if demand spikes | Reduced stockout risk but higher holding costs |

| Inventory Level | Lean, minimal quantities | Additional safety quantity above minimal stock |

| Use Case | Stable demand, predictable supply | Uncertain demand, variable lead times |

Understanding Minimal Stock in Retail Operations

Minimal stock in retail operations represents the lowest inventory level maintained to meet immediate customer demand without interruption, ensuring efficient cash flow and reduced holding costs. It accounts for predictable sales patterns and lead times, minimizing excess stock while preventing stockouts. Accurate calculation of minimal stock leverages sales forecasts, supplier lead times, and historical demand data to optimize inventory turnover and enhance operational responsiveness.

Defining Safety Stock and Its Role in Inventory

Safety stock serves as a buffer inventory level designed to prevent stockouts caused by demand variability and supply chain disruptions. It is calculated based on factors such as lead time, demand forecast accuracy, and service level targets to ensure continuous product availability. Unlike minimal stock, which represents the lowest acceptable inventory level, safety stock specifically accounts for uncertainties and helps maintain retail operations without interruption.

Key Differences Between Minimal Stock and Safety Stock

Minimal stock represents the absolute lowest inventory level required to continue operations without disruption, while safety stock acts as a buffer to protect against demand variability and supply delays. Minimal stock is calculated based on expected demand during lead time, whereas safety stock accounts for uncertainties and fluctuations in demand and supply chain. Retailers rely on minimal stock to avoid stockouts under normal conditions and safety stock to manage unexpected disruptions.

The Importance of Accurate Demand Forecasting

Accurate demand forecasting plays a critical role in balancing minimal stock and safety stock levels in retail inventory management. Underestimating demand leads to insufficient safety stock, increasing the risk of stockouts and lost sales, while overestimating inflates holding costs and excess inventory. Implementing advanced predictive analytics enables retailers to optimize stock quantities, ensuring product availability without tying up capital in surplus inventory.

Benefits of Maintaining Minimal Stock Levels

Maintaining minimal stock levels in retail reduces carrying costs and frees up capital for other operational investments. It enhances inventory turnover rates, minimizing the risk of obsolescence and reducing storage space requirements. This approach also improves responsiveness to market trends by enabling faster adjustment to demand fluctuations.

Risks Associated with Relying Only on Minimal Stock

Relying solely on minimal stock in retail increases the risk of stockouts during unexpected demand surges or supply chain disruptions, leading to lost sales and diminished customer satisfaction. Without safety stock as a buffer, retailers face higher vulnerability to delays from suppliers, seasonal fluctuations, and forecasting errors. Consequently, minimal stock strategies can jeopardize inventory resilience and financial stability when market conditions become volatile.

How Safety Stock Prevents Stockouts and Lost Sales

Safety stock acts as a buffer inventory in retail, preventing stockouts during unexpected demand surges or supply delays. By maintaining a calculated level of safety stock, retailers ensure continuous product availability, reducing the risk of lost sales and dissatisfied customers. This strategic reserve supports supply chain resilience and strengthens customer loyalty through consistent inventory fulfillment.

Calculating Optimal Safety Stock Quantities

Calculating optimal safety stock quantities involves analyzing demand variability and lead time to prevent stockouts while minimizing holding costs in retail. Incorporating factors such as sales forecasts, supplier lead times, and service level targets ensures the right balance between minimal stock and safety stock. Advanced inventory management systems leverage historical sales data and real-time analytics to optimize safety stock levels effectively.

Balancing Minimal Stock and Safety Stock for Efficiency

Balancing minimal stock and safety stock is crucial for retail efficiency by preventing stockouts while minimizing holding costs. Maintaining minimal stock ensures lean inventory levels, reducing excess capital tied up in unsold products, whereas safety stock acts as a buffer against demand variability and supply chain disruptions. An optimal balance leverages demand forecasting and real-time inventory tracking to align stock levels with consumer demand patterns, improving turnover rates and customer satisfaction.

Best Practices for Inventory Management in Retail

Maintaining optimal inventory levels involves balancing minimal stock to reduce holding costs and safety stock to prevent stockouts during demand fluctuations. Best practices in retail inventory management include analyzing historical sales data, lead times, and supplier reliability to calculate accurate safety stock levels while keeping minimal stock aligned with just-in-time replenishment strategies. Employing inventory management software with real-time tracking enables retailers to adjust stock dynamically, ensuring efficient capital use and enhanced customer satisfaction.

Minimal Stock vs Safety Stock Infographic

difterm.com

difterm.com