Inventory shrinkage in retail pet stores refers to the loss of products due to theft, damage, or administrative errors, while inventory spoilage involves products becoming unsellable due to expiration or degradation. Effective inventory management systems help minimize both shrinkage and spoilage by tracking stock levels and monitoring product shelf life. Reducing these losses improves profitability and ensures customers receive fresh, high-quality pet products.

Table of Comparison

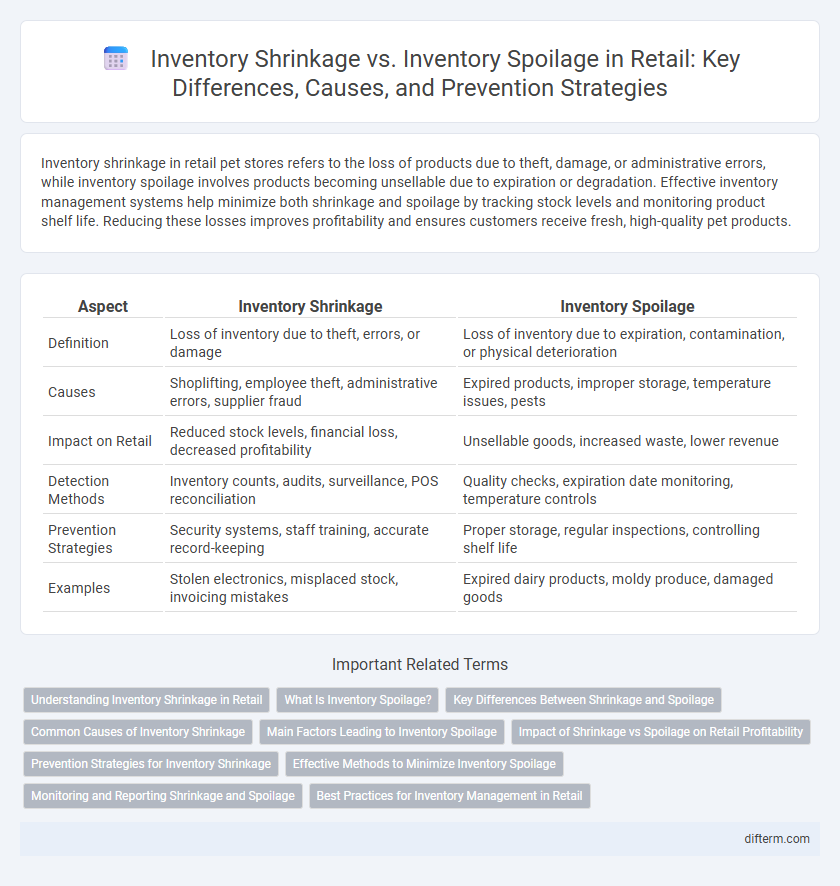

| Aspect | Inventory Shrinkage | Inventory Spoilage |

|---|---|---|

| Definition | Loss of inventory due to theft, errors, or damage | Loss of inventory due to expiration, contamination, or physical deterioration |

| Causes | Shoplifting, employee theft, administrative errors, supplier fraud | Expired products, improper storage, temperature issues, pests |

| Impact on Retail | Reduced stock levels, financial loss, decreased profitability | Unsellable goods, increased waste, lower revenue |

| Detection Methods | Inventory counts, audits, surveillance, POS reconciliation | Quality checks, expiration date monitoring, temperature controls |

| Prevention Strategies | Security systems, staff training, accurate record-keeping | Proper storage, regular inspections, controlling shelf life |

| Examples | Stolen electronics, misplaced stock, invoicing mistakes | Expired dairy products, moldy produce, damaged goods |

Understanding Inventory Shrinkage in Retail

Inventory shrinkage in retail refers to the loss of products between purchase from suppliers and sale to customers, primarily due to theft, administrative errors, or supplier fraud. It significantly impacts profit margins, with the National Retail Federation reporting shrinkage costs retailers approximately $100 billion annually in the U.S. Identifying and controlling shrinkage requires robust loss prevention strategies, accurate inventory tracking systems, and regular audits to differentiate it from inventory spoilage caused by product damage or expiration.

What Is Inventory Spoilage?

Inventory spoilage refers to the loss of stock value due to products deteriorating over time, often caused by expiration, damage, or environmental factors such as humidity and temperature fluctuations. This type of shrinkage directly impacts perishable goods like food, pharmaceuticals, and cosmetics, leading to unsellable inventory and financial loss. Businesses use inventory management systems and regular quality checks to minimize spoilage and maintain accurate stock levels.

Key Differences Between Shrinkage and Spoilage

Inventory shrinkage refers to the loss of products due to theft, administrative errors, or supplier fraud, impacting overall stock accuracy and financial records. Inventory spoilage involves the deterioration or expiration of perishable goods, rendering items unsellable and directly affecting product quality and customer satisfaction. The key difference lies in shrinkage being primarily a result of external or internal misappropriation, while spoilage is caused by natural product degradation over time.

Common Causes of Inventory Shrinkage

Inventory shrinkage in retail primarily results from employee theft, shoplifting, administrative errors, and supplier fraud, significantly impacting profit margins. Poor inventory management, inaccurate record-keeping, and inadequate security measures exacerbate these losses. Unlike inventory spoilage, which involves perishable goods deteriorating over time, shrinkage refers to unaccounted stock reductions due to theft or mismanagement.

Main Factors Leading to Inventory Spoilage

Inventory spoilage in retail mainly results from improper storage conditions, such as temperature fluctuations and humidity, which accelerate product decay. Expired perishable goods, including food and pharmaceuticals, contribute significantly to inventory loss due to strict safety regulations. Additionally, inadequate handling during transportation and shelf stocking increases the risk of physical damage and contamination, intensifying spoilage rates.

Impact of Shrinkage vs Spoilage on Retail Profitability

Inventory shrinkage, caused by theft, errors, or fraud, directly reduces sellable stock and results in immediate revenue loss for retailers. Inventory spoilage, often due to expiration or poor storage conditions, leads to unsellable products that increase operational costs and erode profit margins. Shrinkage typically has a more significant impact on retail profitability because it affects inventory accuracy and triggers additional security and loss prevention expenses.

Prevention Strategies for Inventory Shrinkage

Inventory shrinkage, primarily caused by theft, administrative errors, and supplier fraud, demands targeted prevention strategies such as implementing advanced surveillance systems, regular inventory audits, and employee training programs. Utilizing inventory management software with real-time tracking and barcode scanning enhances accuracy and deters unauthorized access. Establishing strict supplier controls and conducting background checks further minimizes shrinkage risks, optimizing retail profitability.

Effective Methods to Minimize Inventory Spoilage

Inventory spoilage, caused by product expiration, damage, or environmental factors, leads to costly losses in retail operations, distinct from inventory shrinkage which primarily involves theft or administrative errors. Implementing strict temperature controls, regular stock rotation using the First-In-First-Out (FIFO) method, and accurate demand forecasting significantly minimize spoilage. Leveraging real-time inventory management systems and employee training further enhances product handling and reduces waste.

Monitoring and Reporting Shrinkage and Spoilage

Monitoring inventory shrinkage involves tracking discrepancies between recorded and actual stock levels caused by theft, administrative errors, or damage, using regular cycle counts and audit reports. Reporting shrinkage requires detailed documentation of loss incidents and integrating these findings into inventory management systems for real-time visibility and corrective action. Spoilage monitoring focuses on perishable goods, employing expiration date tracking and quality control checks, while spoilage reporting highlights product deterioration patterns to optimize stock rotation and reduce waste.

Best Practices for Inventory Management in Retail

Effective inventory management in retail minimizes both inventory shrinkage and spoilage by implementing robust tracking systems and regular audits. Leveraging real-time inventory data and adopting first-in, first-out (FIFO) practices reduce losses from theft, damage, and product expiration. Integrating technology such as barcode scanning and RFID enhances accuracy, ensuring optimal stock levels and product quality.

Inventory Shrinkage vs Inventory Spoilage Infographic

difterm.com

difterm.com