Embodied energy refers to the total energy consumed during the production, transportation, and installation of pet products, including materials and manufacturing processes. Operational energy accounts for the energy used throughout the pet product's lifespan, such as cleaning, maintenance, and usage. Evaluating both embodied and operational energy is crucial for reducing the overall environmental impact of pet care items.

Table of Comparison

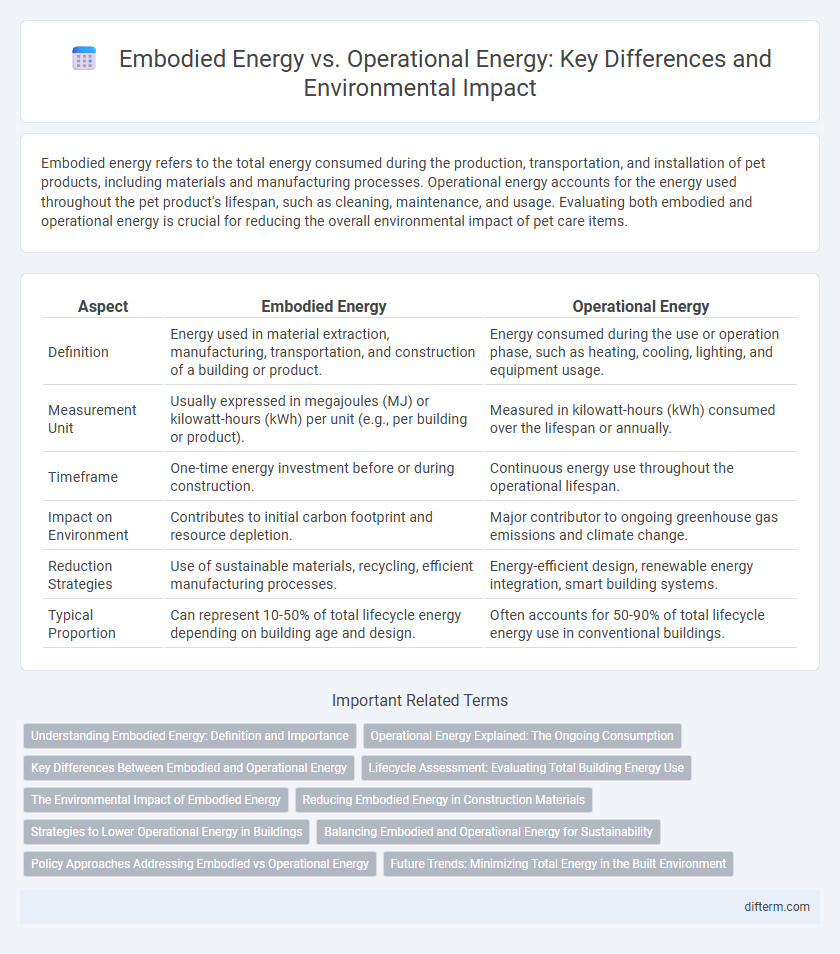

| Aspect | Embodied Energy | Operational Energy |

|---|---|---|

| Definition | Energy used in material extraction, manufacturing, transportation, and construction of a building or product. | Energy consumed during the use or operation phase, such as heating, cooling, lighting, and equipment usage. |

| Measurement Unit | Usually expressed in megajoules (MJ) or kilowatt-hours (kWh) per unit (e.g., per building or product). | Measured in kilowatt-hours (kWh) consumed over the lifespan or annually. |

| Timeframe | One-time energy investment before or during construction. | Continuous energy use throughout the operational lifespan. |

| Impact on Environment | Contributes to initial carbon footprint and resource depletion. | Major contributor to ongoing greenhouse gas emissions and climate change. |

| Reduction Strategies | Use of sustainable materials, recycling, efficient manufacturing processes. | Energy-efficient design, renewable energy integration, smart building systems. |

| Typical Proportion | Can represent 10-50% of total lifecycle energy depending on building age and design. | Often accounts for 50-90% of total lifecycle energy use in conventional buildings. |

Understanding Embodied Energy: Definition and Importance

Embodied energy represents the total energy required to extract, manufacture, transport, and assemble building materials before the structure becomes operational. This initial energy investment significantly impacts a building's overall environmental footprint, often accounting for a substantial portion of its life cycle energy consumption. Understanding embodied energy is crucial for making informed decisions that reduce carbon emissions and promote sustainable construction practices.

Operational Energy Explained: The Ongoing Consumption

Operational energy refers to the ongoing consumption of energy required to run and maintain a building or system throughout its lifecycle. It includes electricity for lighting, heating, cooling, ventilation, and equipment use, accounting for the majority of a building's total energy use over time. Reducing operational energy through efficient design and renewable energy sources is critical for lowering overall environmental impact and achieving sustainability goals.

Key Differences Between Embodied and Operational Energy

Embodied energy refers to the total energy consumed during the extraction, manufacturing, transportation, and construction of building materials, while operational energy is the energy used for heating, cooling, lighting, and powering appliances throughout the building's lifecycle. Embodied energy is a one-time upfront investment, predominantly influencing the environmental impact during the building's construction phase. In contrast, operational energy represents a continuous consumption linked to the building's performance and efficiency over time.

Lifecycle Assessment: Evaluating Total Building Energy Use

Lifecycle assessment of buildings emphasizes the significance of embodied energy--the total energy consumed in material extraction, manufacturing, transportation, and construction--alongside operational energy used during the building's occupancy. Studies reveal that embodied energy can represent up to 30-50% of a building's total energy use over its lifespan, especially in energy-efficient or net-zero designs where operational energy is minimized. Accurate evaluation through lifecycle assessment models supports informed decisions to reduce overall environmental impacts by optimizing both embodied and operational energy components.

The Environmental Impact of Embodied Energy

Embodied energy represents the total energy consumed during the extraction, manufacturing, transportation, and construction of building materials, often accounting for a significant portion of a building's life cycle energy use. This energy contributes to carbon emissions long before a building becomes operational, highlighting the importance of material selection and sustainable construction practices. Reducing embodied energy through recycled materials and efficient design can significantly minimize the overall environmental impact of built environments.

Reducing Embodied Energy in Construction Materials

Reducing embodied energy in construction materials significantly decreases the overall carbon footprint of buildings by minimizing energy consumption during extraction, manufacturing, and transportation phases. Utilizing low-impact materials like recycled steel, bamboo, and rammed earth reduces reliance on energy-intensive products such as concrete and aluminum. Prioritizing locally sourced and renewable materials further cuts embodied energy, enhancing sustainability in the construction industry.

Strategies to Lower Operational Energy in Buildings

Integrating energy-efficient HVAC systems and advanced building automation technologies significantly reduces operational energy consumption in buildings. Utilizing renewable energy sources such as solar panels and implementing smart lighting controls further optimize energy use during occupancy. Regular maintenance and occupant behavior adjustments also play crucial roles in minimizing operational energy demands.

Balancing Embodied and Operational Energy for Sustainability

Balancing embodied energy, the total energy consumed in materials extraction, manufacturing, and construction, with operational energy, the energy used during a building's lifespan, is crucial for sustainable design. Reducing embodied energy through low-impact materials and efficient construction methods complements ongoing energy-efficient operations like HVAC and lighting systems. Optimizing both energy components leads to lower overall carbon footprints and supports long-term environmental sustainability goals.

Policy Approaches Addressing Embodied vs Operational Energy

Policy approaches addressing embodied energy prioritize reducing carbon emissions through material efficiency, circular economy principles, and low-impact construction methods. Governments incentivize operational energy savings via building codes, energy performance standards, and renewable energy integration in building systems. Holistic frameworks increasingly combine embodied and operational energy targets to achieve comprehensive decarbonization in the built environment.

Future Trends: Minimizing Total Energy in the Built Environment

Future trends in the built environment emphasize reducing total energy consumption by integrating low embodied energy materials with highly efficient operational systems. Advances in building design prioritize renewable energy sources and smart technologies to optimize both embodied and operational energy throughout a building's lifecycle. Emerging standards and policies increasingly mandate holistic energy assessments, driving innovation toward sustainable construction and energy use reduction.

embodied energy vs operational energy Infographic

difterm.com

difterm.com